Vibrating Feeder Hammer Hardfacing Methods

Tungsten Carbide Hardfacing from Hardface Technologies

Postalloy® PS-98 Matrix hardfacing wire, alloyed with chromium and molybdenum is developed primarily to be used in conjunction with the MIG Carbide Embedding process.

MIG Tungsten Carbide Feeder Hardface Technologies

Postalloy® DURAMAX vibratory feeder is an automated hardfacing system used to deliver tungsten carbide particles into a molten weld puddle through the (GMAW) Gas Metal Arc

Vibrating Feeder Design StockpileReclaim General

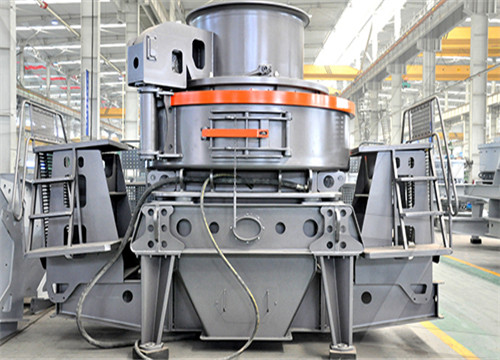

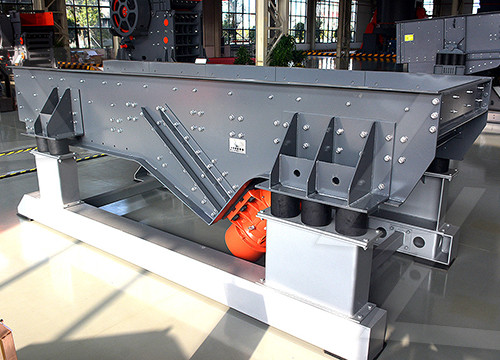

Vibrating Feeder Design Types: The mechanism for producing the vibratory forces can be classified as follows: 1. Direct-force type in

Vibrating feeder Schenck Process

Vibrating feeder. No easy task. When medium, heavy or extremely abrasive materials have to be transported over different conveyor lengths from silos or other storage containers.

Hardfacing Products Lincoln Electric

hardfacing. Hardfacing products are available for restoring parts to their original size that have been worn down due to metal-to-metal friction, severe impact, severe abrasion or

Basic Tooling Methods Automation Devices

Select a bowl having a 7° positive track. About 90° from the bowl discharge, install a wiper to permit one level of parts to pass under. Dish out the track under the wiper to allow one row to pass. Install a pressure break so

Pile Driving Part I: Introduction to Hammers and Techniques

2020年2月25日The first impact-vibration hammer was built in the Soviet Union in 1949. This type of hammer involves a vibratory pile driver that imparts both vibrations and impacts while driving the pile. The initial

Chipping Hammer Hardfacing Secret YouTube

2020年12月21日Chipping Hammer Hardfacing Secret YouTube 0:00 / 5:22 Intro Chipping Hammer Hardfacing Secret weldingtipsandtricks 995K subscribers Subscribe 9.9K 281K views

New Transmission Construction Method Uses Vibratory

2017年7月14日Solo-Driver is ATC’s new, patent-pending method for installing foundations using a vibratory hammer. To date, the utility industry has largely relied on two methods for installing transmission structures

Rankin Manual Vibratory Carbide Feeder Broco-Rankin

Rankin's Manual Vibratory Carbide Feeder is simple to operate and provides a unique handheld, automated feeder for all grades of tungsten carbide. It offers: Feeder offers extraordinary efficiency in making tungsten carbide deposits for extreme wear resistance and portable hardfacing applications for ground engagement tools in the

Tungsten Carbide Hardfacing from Hardface Technologies

Postalloy® PS-98 Matrix hardfacing wire, alloyed with chromium and molybdenum is developed primarily to be used in conjunction with the MIG Carbide Embedding process. The most efficient method to deposit tungsten carbide is to use the tungsten carbide embedding process using Postle's vibratory feeder, combined with our Sintered

Vibrating feeder Schenck Process

Schenck Process vibrating feeders are preferably used for discharging bulk solids from silos. They transport medium to large material flows over conveyor routes of varying length. Even very heavy, highly abrasive materials can be discharged under the most difficult of conditions with the aid of our specially designed vibrating feeders.

Vibrating Feeder Design StockpileReclaim General Kinematics

Vibrating Feeder Design Types: The mechanism for producing the vibratory forces can be classified as follows: 1. Direct-force type in which 100 percent of the vibratory forces are produced by heavy centrifugal counterweights. The forces developed are transmitted directly to the deck through heavy-duty bearings.

Basic Tooling Methods Automation Devices

Select a bowl having a 7° positive track. About 90° from the bowl discharge, install a wiper to permit one level of parts to pass under. Dish out the track under the wiper to allow one row to pass. Install a pressure break so that only one part at a time can move around it.

Hardfacing Products Lincoln Electric

hardfacing Hardfacing products are available for restoring parts to their original size that have been worn down due to metal-to-metal friction, severe impact, severe abrasion or abrasion plus impact. Hardfacing products can also be used for overlay to add a protective layer to carbon steel surfaces. Alloy Resources Welding Consumables Packaging

Pile Driving Basics, Common Problems, and Solutions

2021年6月5日Reduce the hammer stroke for low blow counts; increase for high blow counts. However, you may need to choose a different hammer even a different pile type. Hammer Issues. Sometimes the pile driving hammer is the cause of problems. One example is a when the field stroke of a diesel hammer is less than 90% of the calculated

Vibrating feeder SlideShare

2015年2月11日2. TYPES OF VIBRATING FEEDERS 2.1.1) Constructional details of a DFE vibro- feeder 5. 2. TYPES OF VIBRATING FEEDERS 6. 2. TYPES OF VIBRATING FEEDERS Trough/pan/deck is the tray on to which the material is fed from the hopper/bin. It consists of a mother plate (IS-2062 Gr-B/ST-42) and liner (SS- 409M/Tiscral/SAILHARD)

Pile Driving Part I: Introduction to Hammers and Techniques

2020年2月25日The first impact-vibration hammer was built in the Soviet Union in 1949. This type of hammer involves a vibratory pile driver that imparts both vibrations and impacts while driving the pile. The initial impact-vibration hammer was welded to the top of a metallic tube, and the hammer then drove the rube into a variety of soils.

Chipping Hammer Hardfacing Secret YouTube

2020年12月21日Chipping Hammer Hardfacing Secret YouTube 0:00 / 5:22 Intro Chipping Hammer Hardfacing Secret weldingtipsandtricks 995K subscribers Subscribe 9.9K 281K views

Vibratory Feeders Coperion

The advanced control system and feeder electronics include internal sensors which measure acceleration, displacement, load, current and temperature at rates of up to 25,000 times per second. The fast-acting controller then adjusts the vibratory drive signal to maintain clean sinusoidal displacement for optimal mass flow. Available Models V100 V200

Vibratory Feeders Cleveland Vibrator Company

Common applications of vibratory feeding include: Controlled flow of ingredients to mixing tanks Sprinkling toppings or coatings on and dairy products Adding binders and carbons to foundry sand reprocessing systems Chemical additive feeding in the pulp and stone bleaching or chip handling processes Feeding metal parts to heat treating furnaces

Vibration Measurement: The Complete Guide BrüelKjær

VIBRATION MEASUREMENT. Sometimes though, mechanical vibration performs a useful job. For example, we generate vibration intentionally in component feeders, concrete compactors, ultrasonic cleaning baths, rock drills, and pile drivers. Vibration testing machines are used extensively to impart a controlled level of vibration energy to products

Vibrating Feeders Kinergy

The Kinergy Vibrating Feeder, featuring the Kinergy Drive System, controls the rate of flow of bulk solids from storage in the same way a valve adjusts the flow of liquids. More specifically, a smooth, full range of adjustment from zero to the maximum amount output in infinite steps! Circular

Rankin Manual Vibratory Carbide Feeder Broco-Rankin

Rankin's Manual Vibratory Carbide Feeder is simple to operate and provides a unique handheld, automated feeder for all grades of tungsten carbide. It offers: Feeder offers extraordinary efficiency in making tungsten carbide deposits for extreme wear resistance and portable hardfacing applications for ground engagement tools in the

Tungsten Carbide Hardfacing from Hardface Technologies

Postalloy® PS-98 Matrix hardfacing wire, alloyed with chromium and molybdenum is developed primarily to be used in conjunction with the MIG Carbide Embedding process. The most efficient method to deposit tungsten carbide is to use the tungsten carbide embedding process using Postle's vibratory feeder, combined with our Sintered

Vibrating Feeders Kinergy

The Kinergy Vibrating Feeder, featuring the Kinergy Drive System, controls the rate of flow of bulk solids from storage in the same way a valve adjusts the flow of liquids. More specifically, a smooth, full range of adjustment from zero to the maximum amount output in infinite steps! Circular

Pile Driving Basics, Common Problems, and Solutions

2021年6月5日Reduce the hammer stroke for low blow counts; increase for high blow counts. However, you may need to choose a different hammer even a different pile type. Hammer Issues. Sometimes the pile driving hammer is the cause of problems. One example is a when the field stroke of a diesel hammer is less than 90% of the calculated

How Does Vibro Hammer Work? How To Use Vibro Hammer

OMS Vibro Hammer Machines also known as vibro drivers and vibratory hammers work on the idea of reducing the resistance of the ground with vibration and by changing the formation of the ground. The vibratory piling machine transfers vertical vibrations to the pile via the hydraulic clamp.

Vibrating feeder SlideShare

2015年2月11日2. TYPES OF VIBRATING FEEDERS 2.1.1) Constructional details of a DFE vibro- feeder 5. 2. TYPES OF VIBRATING FEEDERS 6. 2. TYPES OF VIBRATING FEEDERS Trough/pan/deck is the tray on to which the material is fed from the hopper/bin. It consists of a mother plate (IS-2062 Gr-B/ST-42) and liner (SS- 409M/Tiscral/SAILHARD)

Pile Driving Part I: Introduction to Hammers and Techniques

2020年2月25日The first impact-vibration hammer was built in the Soviet Union in 1949. This type of hammer involves a vibratory pile driver that imparts both vibrations and impacts while driving the pile. The initial impact-vibration hammer was welded to the top of a metallic tube, and the hammer then drove the rube into a variety of soils.

Chipping Hammer Hardfacing Secret YouTube

2020年12月21日Chipping Hammer Hardfacing Secret YouTube 0:00 / 5:22 Intro Chipping Hammer Hardfacing Secret weldingtipsandtricks 995K subscribers Subscribe 9.9K 281K views

New Transmission Construction Method Uses Vibratory Hammer

2017年7月14日Solo-Driver is ATC’s new, patent-pending method for installing foundations using a vibratory hammer. To date, the utility industry has largely relied on two methods for installing transmission structures when a concrete base is not needed: direct bury and traditional vibratory installation. With Solo-Driver, now there is a third choice

Vibration Measurement: The Complete Guide BrüelKjær

VIBRATION MEASUREMENT. Sometimes though, mechanical vibration performs a useful job. For example, we generate vibration intentionally in component feeders, concrete compactors, ultrasonic cleaning baths, rock drills, and pile drivers. Vibration testing machines are used extensively to impart a controlled level of vibration energy to products

Vibrating Feeders General Kinematics

Vibrating Feeders. General Kinematics Two-Mass Vibratory Feeders are ruggedly designed for the most demanding applications. This load responsive design takes on even the most challenging material load surges to keep your process flowing smoothly. The low maintenance high uptime design alleviates maintenance headaches and increases

DURAMAX d3qkr296kcvank.cloudfront.net

VIBRATORY FEEDER SYSTEM Postalloy® DURAMAX vibratory feeder is an automated hardfacing system used to deliver tungsten carbide particles into a molten weld puddle through the (GMAW) Gas Metal Arc Welding process. SYSTEM FUNCTIONS AND DESCRIPTION Power is supplied to the system via 110 or 220 volts depending which