List Of International Rock Crusher Or Mining Use Products

Jaw Crushers Mt Baker Mining and Metals

Jaw Crushers Mt. Baker Mining and Metals’ jaw crushers are ready-to-run, right out of the crate. They are engineered for long life, with low energy consumption and durable, industrial-grade moving parts. Applications for

Crushing Equipment Superior Industries U.S.

In the middle part of the 2010’s, Superior launched an aggressive strategy to improve reliability and performance of the products serving the

Mining Tools in 2022—A Guide to Mining Equipment and

Types of Mining MethodsMining Tools and EquipmentMiner ToolsMining PPESurface Mining EquipmentUnderground Mining EquipmentOther Mining Tools

Here are all the types of mining tools used in underground mining: 1. Crane lifts 2. Continuous miners 3. Drones 4. Jumbo drills 5. Loaders and haulers 6. Longwall mining machines 7. Personnel vehicles 8. Refuge chambers 9. Rock dusters 10. Roof bolters 11. Scoops 12. Shotcrete machines 13. Shuttle cars 14. Underground rails 15. Ventilation systems

Types of Rock Crushers Quarry Crushing Equipment

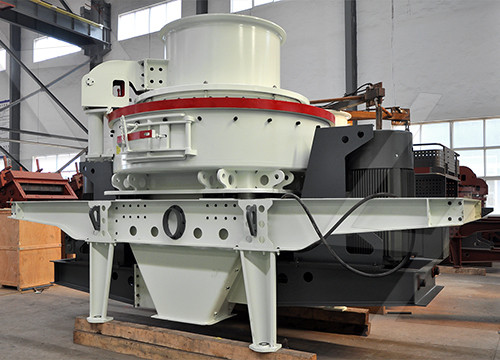

Impact-style crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone.

Home Mt Baker Mining and Metals

MBMM AT A GLANCE. World leader in design and manufacturer of small and medium scale hard rock ore processing and high-performance gravity concentration systems. Unique solutions for value-added benefits to

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries. At present, there are two types of stone crushing

Rock Crushers Best 2023 Models 911Metallurgist

Large Industrial Rock Crushers Cone Crusher (36″) 20 to 50 TPH US$ 100,000 Symons Cone Crushers >50 TPH US$ 150,000 ALL LABORATORY CRUSHERS 8″ Double Roll Crusher US$ 7,000 Roll

Rock Crushing Process in Mining Mineral Processing

2015年7月18日Rock Crusher Types Coarse crushers or breakers for rock are the jaw crusher, gyratory crusher, single- roll crusher, sledging or slugging roll, HPGR, and occasionally, the impact crusher. Intermediate

sbm/sbm list of international rock crusher or mining use

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

A world leader in rock processing solutions for the mining and construction industries. Our constantly evolving offering for mining and construction covers crushing, screening, breaking, demolition and service solutions. No matter the application, we'll ensure you're matched with the right solutions to maximize your productivity and

Rock Crushers, Stone Crushers, Screening and

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers

Crushing Metso Outotec

The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations. The Foresight™ Stations are focused on smart controls and automation for optimal productivity.

Mining Tools in 2022—A Guide to Mining Equipment and Mining

Here are all the types of mining tools used in surface mining: Blasthole drills Bucket-wheel excavators Dozers Dragline excavators Graders Highwall miners Mining trucks Shovels Wheel tractor scrapers Blasthole drills Blasthole drills are mining machines that drill holes into the earth’s surface for placing explosives.

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

Crushing in Mineral Processing

2015年12月26日Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a

11.19.2 Crushed Stone Processing and Pulverized Mineral

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to 1 inch), is returned to the sizing screen.

Rock Crushing Process in Mining Mineral Processing

2015年7月18日First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens. The coarse material that can’t fall through will remain to be crushed with the next gyration.

sbm/sbm list of international rock crusher or mining use products

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

github

international rock crusher mining use products. Rock Crusher Price,WholesaleSuppliers. 2.The applications of Heavy mining equipment of small cone rock crusher price in Turkey M

Common Types of Mining Equipment Used in the Mining Industry

2021年3月25日Material processing: The final step involves grinding, separating, crushing, refining, and smelting mined ore or other goods at an off-site plant to turn them into finished products. Surface Mining. Surface mining includes numerous techniques and is the most common method for non-fuel minerals, producing 97% of the amount mined. Miners

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Gyratories are compression crushers primarily used for heavy mining and quarried materials in extremely high tonnage applications. They provide a reduction ratio of 4:1 to 7:1. The main features of a Gyratory Crusher include a tall crushing chamber lined with replaceable manganese wear plates, a main shaft with head and mantle, and a

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023年2月15日4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it is contaminated. 6 Remove the fines or sticky material in the crushing chamber.

60 X 100 Jaw Crusher for Gold Mining, Granite, Concrete, Gravel, Rock

Find many great newused options and get the best deals for 60 X 100 Jaw Crusher for Gold Mining, Granite, Concrete, Gravel, Rock Crushing at the best online prices at eBay! Free shipping for many products!

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

A world leader in rock processing solutions for the mining and construction industries. Our constantly evolving offering for mining and construction covers crushing, screening, breaking, demolition and service solutions. No matter the application, we'll ensure you're matched with the right solutions to maximize your productivity and

Rock Crushers, Stone Crushers, Screening and

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers

Crushing Metso Outotec

The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations. The Foresight™ Stations are focused on smart controls and automation for optimal productivity.

Mining Tools in 2022—A Guide to Mining Equipment and Mining

Here are all the types of mining tools used in surface mining: Blasthole drills Bucket-wheel excavators Dozers Dragline excavators Graders Highwall miners Mining trucks Shovels Wheel tractor scrapers Blasthole drills Blasthole drills are mining machines that drill holes into the earth’s surface for placing explosives.

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

Common Types of Mining Equipment Used in the Mining Industry

2021年3月25日Material processing: The final step involves grinding, separating, crushing, refining, and smelting mined ore or other goods at an off-site plant to turn them into finished products. Surface Mining. Surface mining includes numerous techniques and is the most common method for non-fuel minerals, producing 97% of the amount mined. Miners

Crushing in Mineral Processing

2015年12月26日Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a

11.19.2 Crushed Stone Processing and Pulverized Mineral

crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers. Oversize material from the top deck of the sizing screen is fed to the tertiary crusher. The tertiary crusher output, which is typically about 0.50 to 2.5 centimeters (3/16th to 1 inch), is returned to the sizing screen.

Rock Crushing Process in Mining Mineral Processing

2015年7月18日First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens. The coarse material that can’t fall through will remain to be crushed with the next gyration.

sbm/sbm list of international rock crusher or mining use products

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

github

international rock crusher mining use products. Rock Crusher Price,WholesaleSuppliers. 2.The applications of Heavy mining equipment of small cone rock crusher price in Turkey M

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Gyratories are compression crushers primarily used for heavy mining and quarried materials in extremely high tonnage applications. They provide a reduction ratio of 4:1 to 7:1. The main features of a Gyratory Crusher include a tall crushing chamber lined with replaceable manganese wear plates, a main shaft with head and mantle, and a

Rock Crushers Gold Prospecting Mining Equipment Detectors

A rock crusher can be an invaluable tool if it has been designed and built by miners for miners just like you'll find below. Tough machines built well and rigorously tested in the field means less work for you. Warranted by the manufacturers. Powered Rock Crushers. Electric or gas powered rock crushers for larger amounts of gold bearing rock.

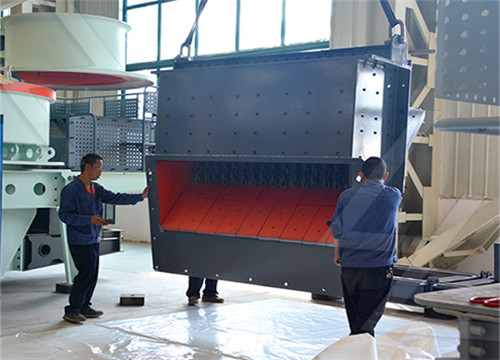

4 Types of Stone Crushers' Maintenance and Efficient Improvement

2023年2月15日There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. How to make your crushers efficiency