Vs 40 Vibrating Screen

How To Size and Select a Vibrating Screen for an

2022年2月15日Sizing Vibratory Screens Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen

Linear vibrating screens LinaClass® Schenck Process

The applications are wide-ranging. Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is

进一步探索

VSMA Vibrating Screens Handbook PDFThe working principle and structure of the linear vibratin根据热度为您推荐•反馈

Vibrating Screen Working Principle Mineral Processing

IntroductionNamingMechanismApplicationsPurposeCauseUseSpecificationsSafetyOperationAssessmentCriticismsAnalysisExampleAdvantagesConstructionTypesDesign

The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when this wheel is rotated. You will find these simple screens in smaller operations and rock qua...

Woven Wire Mesh for Vibratory Screens (Definition,

No matter what you call them, vibratory screens are wire screens that are created to fit inside a screening machine for separation. At W.S. Tyler, Vibratory Screens are used to separate particles anywhere from 6 mesh

Screening, Separation and Vibration Mining Technology

Available screening, separation and vibration equipment and services for mining include: Vibrating conveyors, including trough conveyors, hopper discharge units, guided arm

Particle Size US Sieve Series and Tyler Mesh Size

2002年5月15日Linear vibrating sieves move products linearly and differ from circular sieves as they use rectangular screens. Linear sieves can replace a conventional

Trommel Screen VS Vibrating Screen, Which is better?

2020年8月14日The difference between trommel screen and vibrating screen. 1. Different screening methods Vibrating screens and trommel screens are both screening equipment but the two works in two different

Checking the amplitude of a vibrating screen Metso

The amplitude of vibration can be altered by changing the position of the movable counterweight. Such adjustment is performed based on the application. The screening of coarse material demands a higher

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Vibratory Screeners, Sifters,Separators Kason

We offer gravity-fed and in-line pneumatic models with single or multiple screening decks, one imbalanced-weight or two imbalanced-weight gyratory motors, and a wide range of diameters from 18 in (460mm) to 100 in

Vibrating screen SKF

ν = 200 mm 2 /s at 40 °C (105 °F) ν = 16 mm 2 /s at 100 °C (210 °F) Operating viscosity at 75 °C (165 °F) is around 40 mm 2 /s, based on diagram 3. κ = ν/ν 1 = 40/10 = 4 is confirmed; Relubrication interval and quantity. Experience suggests relubricating the bearings in the vibrating screen every 75 h with 30 g of grease.

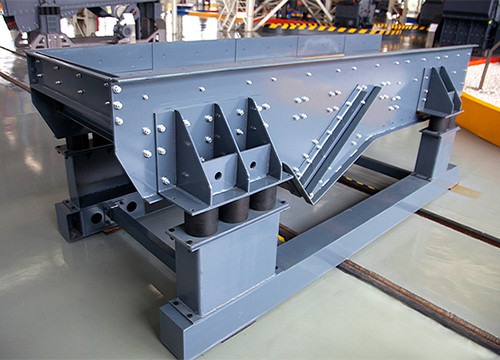

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your equipment. Usable in most applications, these screens come in a wide range of sizes, from 0.9m to 4.8m wide and up to 11.0m long. BRU Vibrating Screens are available in

Linear vibrating screens LinaClass® Schenck Process

The applications are wide-ranging. Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad

Screening, Separation and Vibration Mining Technology

Available screening, separation and vibration equipment and services for mining include: Vibrating conveyors, including trough conveyors, hopper discharge units, guided arm troughs and spiral conveyors. Advanced separation solutions using X-ray fluorescence technique and high-resolution RGB camera.

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Checking the amplitude of a vibrating screen

In the chart below, one can see and verify the shape of the vibratory motion: circular (A), elliptical (B) or even linear (C). Shape of the motion. It is also possible to assess the amplitude of motion, as provided in the illustration

Trommel Screen VS Vibrating Screen, Which is better?

2020年8月14日The screening effect of the trommel screen will be better. For screening dry materials, the vibrating screen is not easy to block holes, and the screening effect is better. 6. Different screening accuracy. The

SCREEN CAPACITY CALCULATION MetallurgistMineral

VIBRATING SCREEN CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency. It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or system.

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

Syntron Material Handling Vibrating Screens

Vibrating Screens. From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water bulk products. Powered by highly efficient electromagnetic drives which provide gentle handling with minimal product degradation, Syntron screen

7 Differences Between Linear Screen and Circular Vibrating Screen

2020年12月7日1. Movement track. The material on the linear screen moves forward in a straight line, and the material on the circular vibrating screen moves in a circular motion. 2. Vibration exciter. The linear vibrating screen exciter is composed of two shafts and works by the principle of vibration motor excitation, so it is also called a double shaft

Vibrating Screen Types Blog

Inclined Screen. Inclined screens are the most basic type of screen, fixed to an inclined frame at an angle of between 15° and 30°. The entire body of the screen vibrates on helical springs circularly with the same characteristics and material flow is supplied by gravitational acceleration. The slope of the inclined screen is fixed, although

Vibrating screen SKF

ν = 200 mm 2 /s at 40 °C (105 °F) ν = 16 mm 2 /s at 100 °C (210 °F) Operating viscosity at 75 °C (165 °F) is around 40 mm 2 /s, based on diagram 3. κ = ν/ν 1 = 40/10 = 4 is confirmed; Relubrication interval and quantity. Experience suggests relubricating the bearings in the vibrating screen every 75 h with 30 g of grease.

Syntron Material Handling Vibrating Screens

Vibrating Screens. From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water bulk products.

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your equipment. Usable in most applications, these screens come in a wide range of sizes, from 0.9m to 4.8m wide and up to 11.0m long. BRU Vibrating Screens are available in

Vibratory ScreenVibrating Sieves Russell Finex

Round vibrating screeners use a circular vibratory motion and are suited to both liquid and powder applications. While both linear and circular sieves use vibration to process materials, circular screening machines tend to

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

Particle Size US Sieve Series and Tyler Mesh Size Equivalents AZoM

2002年5月15日Linear vibrating sieves move products linearly and differ from circular sieves as they use rectangular screens. Linear sieves can replace a conventional conveyor belt to separate products efficiently. They are used for applications such as dewatering and for products that contain a lot of oversized particles.

Screening, Separation and Vibration Mining Technology

Available screening, separation and vibration equipment and services for mining include: Vibrating conveyors, including trough conveyors, hopper discharge units, guided arm troughs and spiral conveyors. Advanced separation solutions using X-ray fluorescence technique and high-resolution RGB camera.

SCREEN CAPACITY CALCULATION MetallurgistMineral

VIBRATING SCREEN CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency. It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or system.

Vibrating Screen vs Trommel? bulk-online

2008年3月4日Dear Bulkoholics, May somebody kindly advise me which one of vibrating/trommel screen is recommended in the outlet of a SAG mill (SBC circuit) with a new feed capacity around 900 mt/h copper ore with about 20% circulating load. If a trommel is considered for the case what is the dimension of such trommel? The circuit

Basic concepts of vibrating screens: What they are,

Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size,

Exciter MechanismsVibration Types MEKA MEKA

Vibration is transmitted to the screen deck by the exciter (vibrator) assembly. The vibrator assembly comprises eccentric masses mounted on the exciter shaft. The shaft is supported on either two or four (depending on the capabilities of the bearing and housing design) vibration screen duty self-aligning double row spherical roller bearings.

Circular vs. Linear, Round Vibrating Screens VibraScreener

Linear Vibrating Screens. The main difference with a linear vibrating screen is that its motion is linear. It uses a vibrating motor to throw materials in an upward and forward linear motion. These models typically operate with twin-vibrating motors that function in a synchronized fashion and move the centrifugal force parallel to the motor access.

Screening/Sizing McLanahan

To size and separate material, screening equipment employs a vibrating or tumbling action that causes the feed material to divide by size. The screen media removable, easily replaceable panels attached to the deck frame through which undersized particles pass makes the separation by allowing smaller particles to pass through its openings.