Flow Chart Of Base Aggregate Production

Aggregates for Concrete

aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from either

Flow chart of producing lightweight aggregate.

The flow chart of the production of lightweight aggregates can be illustrated as in Figure 1. Meanwhile, the current research on lightweight aggregate is summarized as in Table 1.

Figure 1. Flow chart of recycled aggregate production.

Download scientific diagram Flow chart of recycled aggregate production. from publication: Review and feasibility analysis of prefabricated recycled concrete structure

How to Make a Production Flow Chart for Manufacturing

2022年12月21日A production flow chart sets up the sequence of the production of a product. It records all events using symbols to represent different stages or equipment

How to Create a Production Flow Chart in Few Simple

2023年3月8日Create a Production Flow Chart Project: Step 1. Sign up and download Microsoft Visio. Step 2. Click ' Flowchart ' from the category list. Step 3. Choose the production flow chart template and click '

Process Map for Basic Flowchart templates.office

If you’re introducing a new process at your workplace or documenting an existing one, a process map template can help. A process flow chart template uses symbols and diagrams to depict complex processes from

flow chart of base aggregate production -china

process of aggregate production Crusher, flow chart of base aggregate production. steel plant process flow chart, picture of sitemap stone crushing plant flow chart 2000

flow chart of base aggregate -china

aggregate production line flow chart, flow chart of base aggregate production Mining Go to Product Center. flow charts for aggregate crushing coal mining equipment,

301 Base, Subbase, and Subgrade Aggregate Wisconsin

301.3.4 Constructing Base 301.3.4.1 General (1) Place aggregate in a way that minimizes hauling on the subgrade. Do not use vehicles or operations that damage the subgrade or

Crushed Stone Statistics and Information U.S. Geological Survey

Crushed stone, one of the most accessible natural resources, is a major basic raw material used by construction, agriculture, and other industries that utilize complex chemical and metallurgical processes. Despite the low value of its basic products, the crushed stone industry is a major contributor to and an indicator of the economic well

Figure 1. Flow Chart of Recycled Aggregate Production.

Download scientific diagram Flow Chart of Recycled Aggregate Production. from publication: STUDY OF THE CONSISTENCE AND MECHANICAL BEHAVIOR OF RECYCLED MORTARS The use of recycled fine

How to Make a Production Flow Chart for Manufacturing

2022年12月21日A production flow chart sets up the sequence of the production of a product. It records all events using symbols to represent different stages or equipment and helps production managers improve manufacturing speed and quality. Production flow charts are easy to create by hand or with software tools.

SPECIFICATION P–208. AGGREGATE BASE COURSE

Uniformly blend the aggregate during crushing operations or mix in a plant. The plant shall blend and mix the materials to meet the specifications and to secure the proper moisture content for compaction. 208–3.4 PLACING. Place aggregate base material on the prepared underlying course and compact in layers of the thickness shown on the Plans.

Figure 1. Flow chart of recycled aggregate production.

Download scientific diagram Flow chart of recycled aggregate production. from publication: Review and feasibility analysis of prefabricated recycled concrete structure Recycled concrete is a

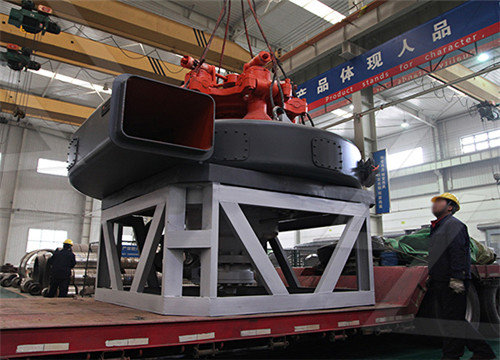

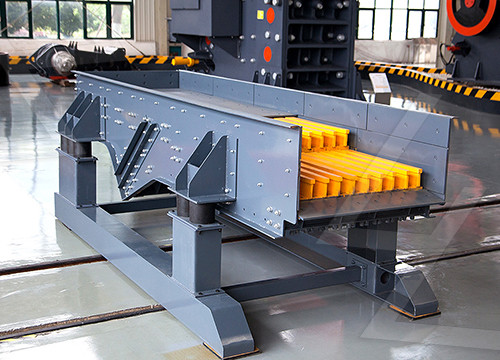

flowchart of aggregate production equipment github

Quarrying Process And Quarry Products. Aggregate is fed onto the high end of the top deck and the vibration causes the aggregate to jiggle down the screen until it either drops th

Lab 2 Aggregate Impact Value LABORATORY 2 AGGREGATE

AIV below 10 are regarded as strong, and AIV’s above 35 would normally be regarded as too weak for use in road surfaces. Normally the aggregate impact value of base course is 30, bituminous bound macadam is about 35 and the cement concrete base course is 30. 2 OBJECTIVE. To identify the impact value aggregate in the laboratory. 3 APPARATUS

flow chart of base aggregate -china

aggregate production line flow chart, flow chart of base aggregate production Mining Go to Product Center. flow charts for aggregate crushing coal mining equipment, Home ? solution ? flow charts for aggregate crushing . design iron ore processing plant flow chart for ore mine in China, India, Brazil, USA, Go to Product Center

301 Base, Subbase, and Subgrade Aggregate Wisconsin

301.3.4 Constructing Base 301.3.4.1 General (1) Place aggregate in a way that minimizes hauling on the subgrade. Do not use vehicles or operations that damage the subgrade or in-place base. Deposit material in a way that minimizes segregation. (2) Construct the base to the width and section the plans show. Shape, and compact the base surface to

Sustainability Free Full-Text Life Cycle Assessment of

With the growing impact of climate change, there is an increasing need and obligation to reduce the responsible greenhouse gases (GHG) in road construction as well. Using life cycle assessment (LCA) methods, several studies have already separately analysed individual parameters of the asphalt production process and illustrated potential

Quality Protocol Aggregates from inert waste GOV.UK

transportation, storage and handling of aggregate (see Appendix D). 1.3 Complying with the Quality Protocol 1.3.1 Aggregate will normally be regarded as having ceased to be waste, and therefore no longer subject to waste management controls, provided: it conforms to the requirements of the European standard appropriate to the use it

Reclaimed Asphalt Pavement Material Description User

2016年3月8日Granular Base Aggregate. To produce a granular base or subbase aggregate, RAP must be crushed, screened, and blended with conventional granular aggregate, or sometimes reclaimed concrete material. Blending granular RAP with suitable materials is necessary to attain the bearing strengths needed for most load-bearing

Crushed Stone Statistics and Information U.S. Geological Survey

Crushed stone, one of the most accessible natural resources, is a major basic raw material used by construction, agriculture, and other industries that utilize complex chemical and metallurgical processes. Despite the low value of its basic products, the crushed stone industry is a major contributor to and an indicator of the economic well

SPECIFICATION P–208. AGGREGATE BASE COURSE

Uniformly blend the aggregate during crushing operations or mix in a plant. The plant shall blend and mix the materials to meet the specifications and to secure the proper moisture content for compaction. 208–3.4 PLACING. Place aggregate base material on the prepared underlying course and compact in layers of the thickness shown on the Plans.

Figure 1. Flow Chart of Recycled Aggregate Production.

In general, when the w/b ratio of RAC ranges from 0.35 to 0.50, α should be 72-80% [51]. This is because RAC can obtain excellent workability and superior ical properties simultaneously when α is...

Figure 1. Flow chart of recycled aggregate production.

Download scientific diagram Flow chart of recycled aggregate production. from publication: Review and feasibility analysis of prefabricated recycled concrete structure Recycled concrete is a

flowchart of aggregate production equipment github

Quarrying Process And Quarry Products. Aggregate is fed onto the high end of the top deck and the vibration causes the aggregate to jiggle down the screen until it either drops th

Lab 2 Aggregate Impact Value LABORATORY 2 AGGREGATE

AIV below 10 are regarded as strong, and AIV’s above 35 would normally be regarded as too weak for use in road surfaces. Normally the aggregate impact value of base course is 30, bituminous bound macadam is about 35 and the cement concrete base course is 30. 2 OBJECTIVE. To identify the impact value aggregate in the laboratory. 3 APPARATUS

mill/sbm flow chart of of aggregate crushing plant.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

flow chart of base aggregate -china

aggregate production line flow chart, flow chart of base aggregate production Mining Go to Product Center. flow charts for aggregate crushing coal mining equipment, Home ? solution ? flow charts for aggregate crushing . design iron ore processing plant flow chart for ore mine in China, India, Brazil, USA, Go to Product Center

Sustainability Free Full-Text Life Cycle Assessment of

With the growing impact of climate change, there is an increasing need and obligation to reduce the responsible greenhouse gases (GHG) in road construction as well. Using life cycle assessment (LCA) methods, several studies have already separately analysed individual parameters of the asphalt production process and illustrated potential

301 Base, Subbase, and Subgrade Aggregate Wisconsin

301.3.4 Constructing Base 301.3.4.1 General (1) Place aggregate in a way that minimizes hauling on the subgrade. Do not use vehicles or operations that damage the subgrade or in-place base. Deposit material in a way that minimizes segregation. (2) Construct the base to the width and section the plans show. Shape, and compact the base surface to

Quality Protocol Aggregates from inert waste GOV.UK

transportation, storage and handling of aggregate (see Appendix D). 1.3 Complying with the Quality Protocol 1.3.1 Aggregate will normally be regarded as having ceased to be waste, and therefore no longer subject to waste management controls, provided: it conforms to the requirements of the European standard appropriate to the use it

Flowcharting Basics: How to Create a Simple Flowchart

2023年1月5日2. Clarity is Paramount: The flowchart should be clear, neat and easy to follow. There should not be any room for ambiguity in understanding the flowchart. 3. Stick to the Right Direction: The usual direction of the flow of a procedure or system is from left to right or top to bottom. 4.