How To Design A Scrap Crushing Machine Based On Pneumatic System

Design and Fabrication of Pneumatic Can Crushing

1.3.3 Pneumatic Can Crusher: A pneumatic type of Can crusher uses compressed air as a working medium for power transmission. The system of operation is similar to that of

Pneumatic Can Crusher Awaits Your Command Hackaday

2021年4月26日The star of the show is a heavy duty wall-mounted can crusher that [Making Stuff] built from some scrap steel and a pneumatic cylinder hooked up to the

PNEUMATIC CAN CRUSHER IRJET-International

supplies the air from the air tank to the direction control valve is gradually opened. The 5/2 direction control valve is operated as can placed in front of the opto sensor. A can

(PDF) Design and Development of Plastic Crusher for a

2020年8月31日The waste plastic crusher consists of four major components: the feeding unit, the crushing unit, the power unit, and the machine frame. The design can be

Safe pneumatic system design

2017年5月1日A safe pneumatic system design starts at the connection to a machine’s air preparation hardware and continues to correctly pairing valves with cylinders. This

Pneumatic Can Crusher From Scrap Metal YouTube

2020年1月16日Pneumatic Can Crusher From Scrap Metal YouTube I had some scrap metal and wanted to use it for a simple project. This video shows my pneumatic can

Pneumatic System Design Considerations

2016年3月21日Pneumatic System Design Considerations. Pneumatic systems as a whole can be simple, but this simplicity can be deceptive when it comes to selecting

how to design a scrap crushing machine based on pneumatic system

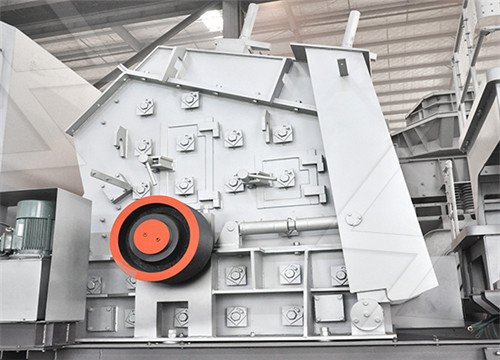

Crushing Plant Design and Layout Considerations. It’s necessary therefore to estimate crusher installation costs based on system design (hopper, feeder, sizer crusher,

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

material and design of the bin varies according to the crushing material. This is so because the crushing force required for crushing the tin is not same as that of the force required

How To Design A Scrap Crushing Machine Based On Pneumatic

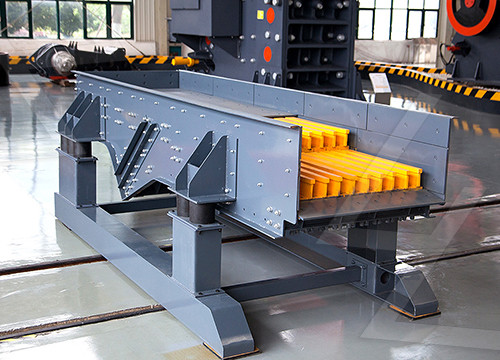

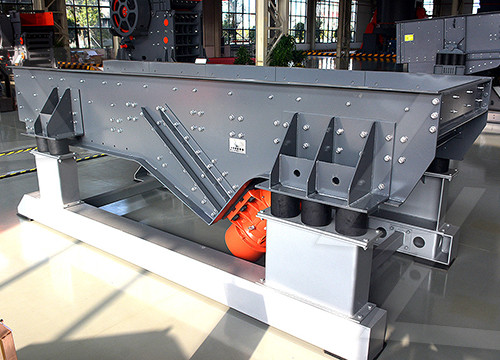

Portable mobile jaw crusher is developed according to novel series stone crushing equipment’s design idea, the adaption Mobile Jaw Crusher Vibrating Feeder is a kind

Design and Fabrication of Pneumatic Can Crushing Machine

1.3.3 Pneumatic Can Crusher: A pneumatic type of Can crusher uses compressed air as a working medium for power transmission. The system of operation is similar to that of hydraulic system except

PNEUMATIC CAN CRUSHER IRJET-International Research

supplies the air from the air tank to the direction control valve is gradually opened. The 5/2 direction control valve is operated as can placed in front of the opto sensor. A can crusher for environmental protection is generally composed of a pneumatic system to drive a piston forward or reverse backward. When the piston is move forward a

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

material and design of the bin varies according to the crushing material. This is so because the crushing force required for crushing the tin is not same as that of the force required for crushing a sheet metal waste or a metal scrap. The material is put into the crusher using a

Development of an automatic can crusher using

2019年6月1日Overall, the system can be controlled manually through the push start and stop button as well as using the Human Machine Interface (HMI) using NB-Designer, for displaying the total of cans...

Safe pneumatic system design

2017年5月1日The pneumatic system design should not only be safe for operators, but also protect the machine from damage. A drop in the air pressure, loss of air pressure or dumping of air pressure during an

Pneumatic System Design Considerations

2016年3月21日The first step in choosing a cylinder is deciding whether to use the single- or double-acting version. As mentioned previously, single-acting cylinders use compressed air to move the load in one direction

Pneumatic Can Crusher From Scrap Metal YouTube

2020年1月16日I had some scrap metal and wanted to use it for a simple project. This video shows my pneumatic can crusher working in action on a few cans.Google Play Appsh...

The General Design of a Pneumatic System and its

The most important elements at the machine-level. The sketch exemplifies a pneumatic system at the machine-level: The individual elements are represented by ISO-symbols, which are connected with lines. They

Simple Pneumatic Machine : 6 Steps (with Pictures) Instructables

Step 4: Add the Pneumatic System. To create a pneumatic system: Fill up one syringe with air, then connect it to the other empty syringe with vinyl tubing. Tightly wrap one end of the pipe cleaner around the syringe as shown, then tie it to the machine arm. Attach the syringe to the frame by taping the spot where the tubing connects to the

How To Design A Scrap Crushing Machine Based On Pneumatic System

Portable mobile jaw crusher is developed according to novel series stone crushing equipment’s design idea, the adaption Mobile Jaw Crusher Vibrating Feeder is a kind of linear-direction feeding equipment, in the mineral

CHAPTER 5: Pneumatic and Hydraulic Systems PowerMotion

2006年10月16日Air-logic controls run on shop air and are actuated by air palm buttons and limit valves to start and continue a cycle. This circuit has an OSHA safe anti tie-down dual palm button start control. The two palm buttons must be operated at almost the same time or the cylinder will not extend.

Latest Pneumatic Projects IdeasTopics Nevonprojects

Design and Fabrication of Pneumatic Bearing Puller Project. Pneumatic Operated Double Hacksaw Project. Automatic Pneumatic Hammer Machine Project. Automatic Pneumatic Paper Cutting Machine Project. Pneumatic Scissor Lift Jack Project. Pneumatic Sand Filtering Project. Pneumatic Paper Cup Making Machine Project.

The Monster Crusher Crushes All Scrap for Recycling YouTube

The Monster Crusher Crushes All Scrap for Recycling! Powerful Shredder Machine! TeamMachines 147K subscribers Subscribe 24M views 3 years ago The Monster Crusher Crushes All Scrap and...

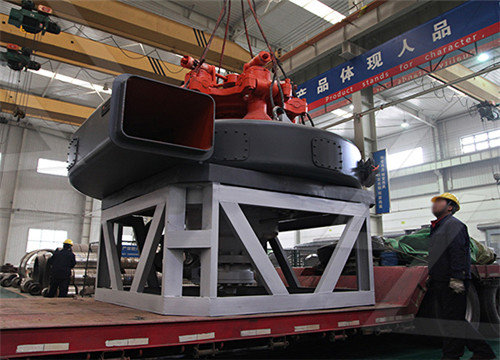

Your Best Metal Crusher Machine Manufacturer in China Fierchina

The crushing material from our metal shredder machine goes through a vibration feeder, belt conveyor, magnetic sorting system. 2. Separate the iron metal, non-ferrous metal, and non-metallic objects, and send them out by their respective conveyors for stacking. 3.

Design and Fabrication of Pneumatic Can Crushing Machine

1.3.3 Pneumatic Can Crusher: A pneumatic type of Can crusher uses compressed air as a working medium for power transmission. The system of operation is similar to that of hydraulic system except

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

material and design of the bin varies according to the crushing material. This is so because the crushing force required for crushing the tin is not same as that of the force required for crushing a sheet metal waste or a metal scrap. The material is put into the crusher using a

Automatic Pneumatic Operated Waste Can Crusher

The Can Crushing machine works with the help of pneumatic Single acting cylinder. The piston is connected to the moving and Pressing Die Arrangement. It is used to press the wastage cool drinks can. The

Safe pneumatic system design

2017年5月1日The pneumatic system design should not only be safe for operators, but also protect the machine from damage. A drop in the air pressure, loss of air pressure or dumping of air pressure during an

Pneumatic Can Crusher From Scrap Metal YouTube

2020年1月16日I had some scrap metal and wanted to use it for a simple project. This video shows my pneumatic can crusher working in action on a few cans.Google Play Appsh...

The General Design of a Pneumatic System and its

The sketch exemplifies a pneumatic system at the machine-level: The individual elements are represented by ISO symbols, which are connected with lines. They display the route of the compressed air. In order to get a

Design and Fabrication of Pneumatic Can Crushing Machine

2020年1月1日The Can crushing machine is designed to crush aluminum waste cans by 80%. reduction in volume. It is used primarily to ease transportation of aluminum waste for recycling purposes. The machine is

how to design a scrap crushing machine based on pneumatic system

2021年2月20日For instance, there are thousands of types, sizes, and variations of cylinders and valves, from off-the-shelf versions to custom designs.How To Design A Scrap Crushing Machine Based On ,Safeguarding Working Around Machinery Osh Answers. 2017 DESIGN AND FABRICATION OF PNEUMATIC CAN CRUSHING MACHINE

How To Design A Scrap Crushing Machine Based On Pneumatic System

Portable mobile jaw crusher is developed according to novel series stone crushing equipment’s design idea, the adaption Mobile Jaw Crusher Vibrating Feeder is a kind of linear-direction feeding equipment, in the mineral

The Monster Crusher Crushes All Scrap for Recycling YouTube

2019年10月27日The Monster Crusher Crushes All Scrap for Recycling! Powerful Shredder Machine! TeamMachines 147K subscribers Subscribe 24M views 3 years ago The Monster

how to design a scrap crushing machine based on pneumatic system

Automatic Pneumatic Operated Waste Can Crusher Machine. The Can Crushing machine works with the help of pneumatic Single acting cylinder. The piston is connected to the moving and Pressing Die Arrangement. It is used to press the wastage cool drinks can. The machine is portable in size, so easy transportable. This describes about the

Latest Pneumatic Projects IdeasTopics Nevonprojects

Design and Fabrication of Pneumatic Bearing Puller Project. Pneumatic Operated Double Hacksaw Project. Automatic Pneumatic Hammer Machine Project. Automatic Pneumatic Paper Cutting Machine Project. Pneumatic Scissor Lift Jack Project. Pneumatic Sand Filtering Project. Pneumatic Paper Cup Making Machine Project.

DESIGN AND FABRICATION OF CRUSHER MACHINE FOR

is less since it does not use hydraulic or pneumatic fluids. power the machine w c. Detail Design with Fabrication Drawings Fig -3: CAD Model The design of the project was prepared using a CAD model. Each part of the model was prepared in Solid Edge and then assembled as shown in Fig-3. d. Fabrication Procedure

Simple Pneumatic Machine : 6 Steps (with Pictures) Instructables

Step 4: Add the Pneumatic System. To create a pneumatic system: Fill up one syringe with air, then connect it to the other empty syringe with vinyl tubing. Tightly wrap one end of the pipe cleaner around the syringe as shown, then tie it to the machine arm. Attach the syringe to the frame by taping the spot where the tubing connects to the