Secondary Machines In Surface Iron Ore

Open-Pit Mining Method and Process Epiroc US

进一步探索

Open-Pit Mining Method and Process Epiroc(PDF) Lecture 4 Open Pit Mining Presentation Academia.Open Pit Mining ProsCons Sciencing(PDF) Open Pit Mining ResearchGateDesign of openpit mining SlideShare根据热度为您推荐•反馈

Iron processing Definition, History, Steps, Uses,Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

Mining Tools in 2022—A Guide to Mining Equipment and

Types of Mining MethodsMining Tools and EquipmentMiner ToolsMining PPESurface Mining EquipmentUnderground Mining EquipmentOther Mining Tools

Here are all the types of mining tools used in underground mining: 1. Crane lifts 2. Continuous miners 3. Drones 4. Jumbo drills 5. Loaders and haulers 6. Longwall mining machines 7. Personnel vehicles 8. Refuge chambers 9. Rock dusters 10. Roof bolters 11. Scoops 12. Shotcrete machines 13. Shuttle cars 14. Underground rails 15. Ventilation systems

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is

Macro machines: The biggest and best mining machinery

2011年12月20日Wirtgen developed the 4200 SM surface miner in conjunction with iron producer Fortescue Metals Group (FMG) as a high

Underground hard-rock mining Wikipedia

Last cleaning of ore is done through remote controlled LHD machines. A system of primary and secondary stopes is often used in VCR mining, where primary stopes are mined in

Ten biggest producing surface mines in North America in 2020

2021年9月8日Here are the ten largest surface mining projects by production in North America in 2020, according to GlobalData’s mining database. 1. Morenci Mine The

Development of Secondary-fuel Injection Technology for

Development of Secondary-fuel Injection Technology for Energy Reduction in the Iron Ore Sintering Process. Nobuyuki Oyama, Yuji Iwami, Tetsuya Yamamoto, it is possible to

Iron Ore Sinter an overview ScienceDirect Topics

E. Donskoi, J.R. Manuel, in Iron Ore, 2015 4.2.2 Sinter. Low-temperature (< 1300 °C) iron ore sinter is an agglomerate of unmelted and partially melted nuclei particles (+ 1

Supergene (geology) Wikipedia

In ore deposit geology, supergene processes or enrichment are those that occur relatively near the surface as opposed to deep hypogene processes. Supergene processes

Open-Pit Mining Method and Process Epiroc US

2021年1月7日SmartROC D65 key to Kaunis Iron. January 7, 2021. 2021 Surface miningquarrying Mining International Surface SmartROC D65 Surface and Exploration Drilling division Customer story. Just two

Mining and Rock Excavation Equipment, Mining Machines

Mining and Rock excavation Products and Mining Equipment Whether you need to excavate, transport or process ore, rock or overburden more efficiently, our comprehensive range of cutting-edge surface and underground mining equipment is designed to increase your productivity and boost your bottom line. Parts and services offering >

Mining Tools in 2022—A Guide to Mining Equipment and Mining Machines

Here's a general list of mining tools and equipment: Miner tools —tools that miners carry on them, like pickaxe and chisels. Mining PPE —equipment that miners use to stay safe while working. Surface mining equipment —all the tools

Iron processing Ores Britannica

Most iron ores are extracted by surface mining. Some underground mines do exist, but, wherever possible, surface mining is preferred because it is cheaper. Lumps and fines Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch).

Minerals Free Full-Text Ore Assimilation and

2019年2月22日During the iron ore sintering process, two types of particles are present in the sinter bed: (1) fines, which are actively taking part in melting and the formation of secondary phases, and (2) coarse

Iron Ore Agglomeration Technologies IntechOpen

2017年12月20日Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made

Automated Optical Image Analysis of Iron Ore Sinter

Sinter quality is a key element for stable blast furnace operation. Sinter strength and reducibility depend considerably on the mineral composition and associated textural features. During sinter optical image analysis (OIA), it is important to distinguish different morphologies of the same mineral such as primary/secondary hematite, and types of

Digging deeper: Mining methods explained Anglo

Open-pit is one of the most common mining methods used and starts from the earth's surface, maintaining exposure to the surface throughout the extraction period. The excavation usually has stepped sides to ensure

Crushing in Mineral Processing

2015年12月26日The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm). This techniques allows for a rock-to-rock relative comparison. The Bond’

12.5 Iron And Steel Production US EPA

The production of 1 ton of iron requires 1.4 tons of ore or other iron bearing material; 0.5 to 0.65 tons of coke; 0.25 tons of limestone or dolomite; and 1.8 to 2 tons of air. Byproducts consist of 0.2 to 0.4 tons of slag, and 2.5 to 3.5 tons of blast furnace gas containing up to 100 pounds (lb) of dust.

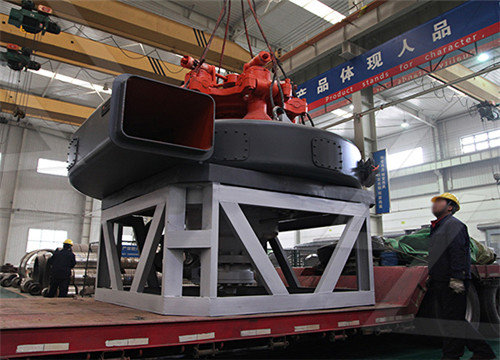

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Eccentric shaft adopt 40Cr steel precise forged, Advanced Movable jaw plate assemble made from high quality casting parts, Tooth-shape plate, deep V-chamber, high manganese steel material ZGMn13-4 make crusher more reliable, Precise casting heavy fly wheel,Jaw crusher frame adopt thick Q235B heavy steel plate welding process.Machine blasting

Explore Minnesota Iron Ore Minnesota Department of

Secondary Iron Ore Recovery and Production. Two Minnesota companies are producing iron ore concentrate from the tailings of previous natural iron ore mining operations. Magnetation LLC. Magnetation LLC is a joint venture between Magnetation, Inc. (50.1%) and AK Steel Corp. (49.9%). Magnetation LLC produces iron ore concentrate from

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”.

Steps in the Modern Steelmaking Process ThoughtCo

2020年8月21日Secondary forming techniques give the steel its final shape and properties. These techniques include: Shaping ( cold rolling ), which is done below the metal's recrystallization point, meaning mechanical stress—not heat—affects change Machining (drilling) Joining (welding) Coating (galvanizing) Heat treatment (tempering)

Open-Pit Mining Method and Process Epiroc US

2021年1月7日SmartROC D65 key to Kaunis Iron. January 7, 2021. 2021 Surface miningquarrying Mining International Surface SmartROC D65 Surface and Exploration Drilling division Customer story. Just two

Minerals Free Full-Text Ore Assimilation and

2019年2月22日During the iron ore sintering process, two types of particles are present in the sinter bed: (1) fines, which are actively taking part in melting and the formation of secondary phases, and (2) coarse

Iron Ore Agglomeration Technologies IntechOpen

2017年12月20日Dwight-Lloyd technology is the main iron ore sintering technology. Basically, this equipment consists in a sintering grate that is a continuous chain of large length and width, which is formed by the union

Automated Optical Image Analysis of Iron Ore Sinter

Sinter quality is a key element for stable blast furnace operation. Sinter strength and reducibility depend considerably on the mineral composition and associated textural features. During sinter optical image analysis (OIA), it is important to distinguish different morphologies of the same mineral such as primary/secondary hematite, and types of

Mining Tools in 2022—A Guide to Mining Equipment and Mining Machines

Here are all the types of mining tools used in surface mining: Blasthole drills Bucket-wheel excavators Dozers Dragline excavators Graders Highwall miners Mining trucks Shovels Wheel tractor scrapers Blasthole drills Blasthole drills are mining machines that drill holes into the earth’s surface for placing explosives.

Digging deeper: Mining methods explained Anglo

Open-pit is one of the most common mining methods used and starts from the earth's surface, maintaining exposure to the surface throughout the extraction period. The excavation usually has stepped sides to ensure

12.5 Iron And Steel Production US EPA

The production of 1 ton of iron requires 1.4 tons of ore or other iron bearing material; 0.5 to 0.65 tons of coke; 0.25 tons of limestone or dolomite; and 1.8 to 2 tons of air. Byproducts consist of 0.2 to 0.4 tons of slag, and 2.5 to 3.5 tons of blast furnace gas containing up to 100 pounds (lb) of dust.

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Eccentric shaft adopt 40Cr steel precise forged, Advanced Movable jaw plate assemble made from high quality casting parts, Tooth-shape plate, deep V-chamber, high manganese steel material ZGMn13-4 make crusher more reliable, Precise casting heavy fly wheel,Jaw crusher frame adopt thick Q235B heavy steel plate welding process.Machine blasting

Changes of SO2, NOx Emission, and Production of Iron Ore

2022年2月4日Change of NO x content in sintering exhaust gas of two machines Full size image On the basis of the industrial tests, it is concluded that the effect of steam injection on NO x reduction is by 12–29 mg/Nm 3, with an average reduction of 7.4%. Effects of Surface Steam Injection on SO 2 Emission

Underground hard-rock mining Wikipedia

Last cleaning of ore is done through remote controlled LHD machines. A system of primary and secondary stopes is often used in VCR mining, where primary stopes are mined in the first stage and then backfilled with cemented fill to provide wall support for the blasting of successive stopes.

Iron processing Ores Britannica

Most iron ores are extracted by surface mining. Some underground mines do exist, but, wherever possible, surface mining is preferred because it is cheaper. Lumps and fines Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch).

TMT Steel bar Manufacturing Process Shyam Steel

The manufacturing process of TMT Bar involves series of processes like rolling, water quenching, heat treatment, cooling at various stages of manufacturing. The Thermo Mechanical Treatment involves 3 essential steps that are: Quenching Self Tempering Atmospheric cooling The quality of TMT Bar depends on three major factors Quality of