Rock Vsi Crusher With Shoe And Anvils Manufacturer

VSI Crushers AGGRETEK Vertical Shaft Impactors

VSI APPLICATIONS Rock and mineral deposits vary widely from site to site, country to country, and around the world. Crushing plants, circuit variations, and product

进一步探索

Vertical shaft impact (VSI) crushers in glass recyclingCone Crusher vs VSI (Vertical Shift Impactor) materialtree根据热度为您推荐•反馈

Vertical Shaft Impact Crushers MEKA CrushingScreening Plants

根据热度为您推荐•反馈

VSI Crushers REMco

VSI Crushers Quality Vertical Shaft Impactors REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits. Feed rates are from 15 to 1500 TPH. Machine drive powers range from

Vertical Shaft Impactor VSI Crushers Impact Crushers

The Pilot Crushtec TwisterTrac VS350E is a fully mobile, diesel hydraulic driven, remote controlled, tracked VSI crusher. This world leading product is fully automated, features variable rotor speed and has a throughput

ISC Crusher Wear Parts Spokane Industries

At Spokane Industries, we provide aftermarket VSI wear parts for ISC Crushers in both standard chrome and our patented Si-Tec® ceramic technology to improve wear life,

Used Vsi Crushers for sale. Cemco equipmentmore

Search for used vsi crushers. Find Cemco, Metso, Remco, Cedarapids, and Fabo for sale on Machinio. Manufacturer: Cemco; 32" SUPER CHIPPER, HYDRAULIC LID

VSI Crusher SpareWear Parts Precision CrushersSpares

Precision CrushersSpares is a manufacturer and supplier of VSI crusher spare and wear parts like Anvils, Impeller shoes, Rim liners, Lid liners, Table liners, Feed tubes,

Ceramic Inserts Anvils Hunan JY Casting

Hunan JY Casting manufactures ceramic inserts anvils for VSI crushers. Anvils and impellers are optimized for greater crusher productivity and to control costs. All provide

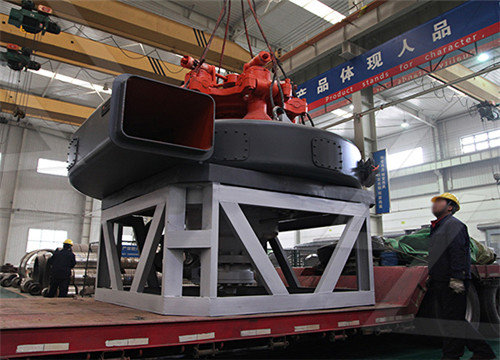

rock vsi crusher with shoe and anvils manufacturer

Rock Crusher Wear Parts Vertical Shaft Impactor Vsi Crusher Parts Shoes, Anvils, Go to Product Center. rock on rock vsi, mpl is a professional types of rock on

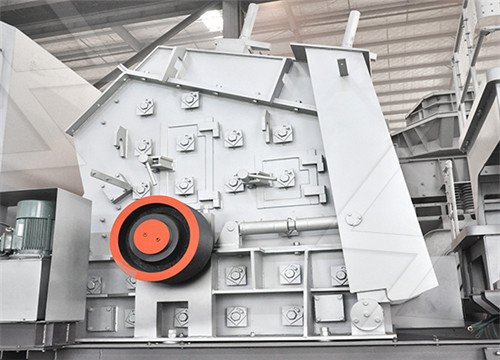

Vertical Shaft Impactors VSI Crushers Stedman Machine

The new Patented Tubular Rotor provides many benefits over the standard shoe and anvil designs as well as rock-shelf applications. The easily replaceable and indexable rotor tubes, cut your total operating cost and maintenance time in half, making V-Slam the easiest VSI crusher to maintain and one of the best impact crushers on the market.

Barmac® B Series™ impact crushers Metso Outotec

Barmac® VSI crushers can be equipped with metallic anvils on request. In anvil solution the rock-on-rock cavity ring is replaced with an anvil ring. The anvil solution improves Barmac® crushers’ reduction ratio and enables finer end products, but wear costs are slightly increased since the anvils must be replaced from time to time.

Barmac® B7150SE™ impact crusher Metso Outotec

Barmac® B7150SE™ VSI crusher is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals. Barmac® B7150SE™ can be equipped with metallic anvils on request. In anvil solution the rock-on-rock cavity ring is replaced with an anvil ring, and the rocks are thrown against metal anvils instead of a rock bed

Vertical Shaft Impactors Product Overview

Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime and maximizing profitability. At Canica®, we offer one of the widest ranges on the market, with open shoe table, enclosed rotor

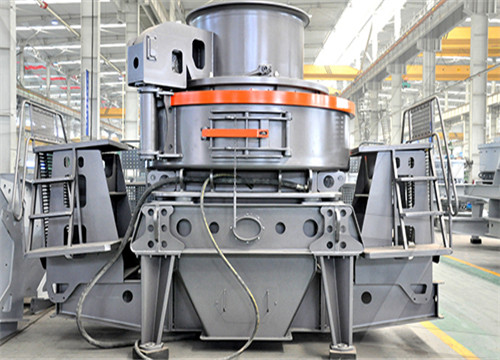

Meka Vertical Shaft Impact Crushers mekaglobal

VERTICAL SHAFT IMPACT CRUSHERS (VSI) CRUSHING CHAMBER CONFIGURATIONS ROCK ON ROCK (ROR) • Enclosed rotor and rock shelf • Feed sizes up to 50mm (2”) • For all rock types and the most abrasive materials • Produces the best shaped and most consistent material with the lowest wear cost ROCK ON ANVIL (Rock

ISC Benefits Isc Vsi

ISC® VSI Crusher Standard Design Features. Adjustable Feed Splash Plate with replaceable cast liners for directing and centering the feed. Cast Lined Rotatable Feed Box. Externally Adjustable Feed Tube Assembly with Rubber Dust Seal and cast Feed Tubes. Quick release Lid Wedges with Chain Tie Downs and Safety Hitch Pin Clip.

Canica VSI VERTICAL SHAFT IMPACT CRUSHERS

Rock on Anvil (ROS Series) Rock on Rock (ROR Series) Shoe and Anvil (HD Series) Test Crushing We offer material test crushing as a free service to ensure the ® Canica VSI crusher selected for your application is the appropriate size and configuration to meet your needs. A full size vertical shaft impact crusher duplicates each of

Vertical Shaft Impactor VSI Crushers Impact Crushers Pilot Crushtec

The Pilot Crushtec TwisterTrac VS350E is a fully mobile, diesel hydraulic driven, remote controlled, tracked VSI crusher. This world leading product is fully automated, features variable rotor speed and has a throughput capacity of up to 350tph. The TwisterTrac can be used on its own or easily integrated into mobile crushing plants.

FAQ REMco

A REMco crusher with an anvil chamber as a tertiary feeding minus 3” (76.2mm) will typically produce minus 3/4” (20mm) for 0.25 to 0.40 cents per ton wear cost. Depending on the nature of the rock being crushed, an anvil chamber has to be changed between once a week to once a year.

ISC Crusher Wear Parts Spokane Industries

At Spokane Industries, we provide aftermarket VSI wear parts for ISC Crushers in both standard chrome and our patented Si-Tec® ceramic technology to improve wear life, lower tonnage costs, and increase uptime and profits. With Anvils, shoes, feed disks and table liners, we provide the most advanced technology for your ISC Crusher.

Vertical Shaft Impactor Armstrong Equipment

The ® WV2000 combines the rugged reliability of our 2000SD Vertical Shaft Impact (VSI) crusher with our efficient and durable inclined screen. The result is a high production crushing and screening machine. The highly mobile WV2000 wheeled plant is suitable for working in many different crushing circuits and will handle almost any

VSI Crusher Magotteaux

Versatile and Efficient: The VSI crushes hard and brittle materials with ease. It is the right choice for handling rock, cement clinker, grinding material, concrete aggregate, and refractory material. As a crusher for building and road-making, the VSI is highly suitable. Simple to Run: The VSI is a solid piece of machinery.

Ceramic Inserts Anvils Hunan JY Casting

Ceramic Inserts Anvils Hunan JY Casting manufactures ceramic inserts anvils for VSI crushers. Anvils and impellers are optimized for greater crusher productivity and to control costs. All provide reduced costs of wear, greater productivity, reduced cost of maintenance, and better safety.

Crushers an overview ScienceDirect Topics

This crusher developed by Jaques (now ® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore. Examples include the Rock on Rock, Rock on Anvil and

Vertical Shaft Impactors VSI Crushers Stedman Machine

V-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive crushers. The V-Slam, with its low horsepower per ton of

Barmac® B7150SE™ impact crusher Metso Outotec

Barmac® B7150SE™ VSI crusher is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals. Barmac® B7150SE™ can be equipped with metallic anvils on request. In anvil solution the rock-on-rock cavity ring is replaced with an anvil ring, and the rocks are thrown against metal anvils instead of a rock bed

Vertical Shaft Impactors Product Overview

Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime and maximizing profitability. At Canica®, we offer one of the widest ranges on the market, with open shoe table, enclosed rotor

Meka Vertical Shaft Impact Crushers mekaglobal

VERTICAL SHAFT IMPACT CRUSHERS (VSI) CRUSHING CHAMBER CONFIGURATIONS ROCK ON ROCK (ROR) • Enclosed rotor and rock shelf • Feed sizes up to 50mm (2”) • For all rock types and the most abrasive materials • Produces the best shaped and most consistent material with the lowest wear cost ROCK ON ANVIL (Rock

Vertical Shaft Impactor Armstrong Equipment

The ® WV2000 combines the rugged reliability of our 2000SD Vertical Shaft Impact (VSI) crusher with our efficient and durable inclined screen. The result is a high production crushing and screening machine. The highly mobile WV2000 wheeled plant is suitable for working in many different crushing circuits and will handle almost any

ISC Benefits Isc Vsi

ISC® VSI Crusher Standard Design Features. Adjustable Feed Splash Plate with replaceable cast liners for directing and centering the feed. Cast Lined Rotatable Feed Box. Externally Adjustable Feed Tube Assembly with Rubber Dust Seal and cast Feed Tubes. Quick release Lid Wedges with Chain Tie Downs and Safety Hitch Pin Clip.

Canica VSI VERTICAL SHAFT IMPACT CRUSHERS

Rock on Anvil (ROS Series) Rock on Rock (ROR Series) Shoe and Anvil (HD Series) Test Crushing We offer material test crushing as a free service to ensure the ® Canica VSI crusher selected for your application is the appropriate size and configuration to meet your needs. A full size vertical shaft impact crusher duplicates each of

FAQ REMco

A REMco crusher with an anvil chamber as a tertiary feeding minus 3” (76.2mm) will typically produce minus 3/4” (20mm) for 0.25 to 0.40 cents per ton wear cost. Depending on the nature of the rock being crushed, an anvil chamber has to be changed between once a week to once a year.

Crusher Wear Parts Parts for Crushers McCourt Equipment

Spokane Industries is an industry leader in crusher wear parts innovation due to its experience and advanced technology. Spokane Industries is well-known for producing high-quality vertical shaft impactor parts such as tables, shoes, anvils, feed disks, and everything in between. Spokane also has blow bars, impact plates, liners, and all of

Ceramic Inserts Anvils Hunan JY Casting

Hunan JY Casting manufactures ceramic inserts anvils for VSI crushers. Anvils and impellers are optimized for greater crusher productivity and to control costs. All provide reduced costs of wear, greater productivity, reduced cost of maintenance, and better safety.

VSI Crusher Magotteaux

Versatile and Efficient: The VSI crushes hard and brittle materials with ease. It is the right choice for handling rock, cement clinker, grinding material, concrete aggregate, and refractory material. As a crusher for building and road-making, the VSI is highly suitable. Simple to Run: The VSI is a solid piece of machinery.

GOLD CRUSH (GC -VSI) Vertical Shaft Impactor

GC-VSI Vertical Shaft Impactor (VSI) crusher uses a unique approach for size reduction involving a high speed rotor with wear resistant tips and a crushing chamber designed to ‘throw’ the rock against. The VSI crusher utilizes velocity rather than pressure as the predominant force to break rock.

REMco Operators Council Newsletter As the Rotor Turns

Producer resorts to rock-on-rock VSI use after many costly years of operating anvil style VSIs Background • Use one rock-on-rock VSI crusher powered by 700 HP (two 350 HP motors) to replace two aging anvil-type Canica VSI crushers powered by 400 HP each (a total of 800 HP). This would result in a 100 HP savings.

Proman- VSI Crusher manufacturer in Bangalore, India

VSI crushers are autogenous rock on rock type used for the reduction and shaping of hard abrasive rocks and ores, and also Rock on Anvil VSI machines for limestone and less abrasive materials. We offer a complete range of REMco VSI Crushers from 50 HP to 1500HP (20 TPH to 1500 TPH) in the following categories