Equipment Solid Feeder Belt Conveyor Cost

Conveyor / Feeder / Stacker Aggregate Equipment For Sale

根据热度为您推荐•反馈根据热度为您推荐•反馈

Conveyor Belts McMaster-Carr

Belt Conveyors. Belting for Slider-Bed Conveyors. This belting has a smooth surface.

Used Incline/Cleated Equipment — Machine for Sale

Service Engineering, incline, cleated belt, stainless steel feeder. Equipped with a 38" long x 42" wide x 15" deep product hopper with flip top lid, 70" long x 12" wide Neoprene belt conveyor with 2" high cleats on 6" centers,

Solids feeders information for bulk handling BulkInside

2023年2月2日Solids feeders deliver powder, granular, and other bulk solid materials along a process line, or to and from process units, storage bins, conveyors, and product

Belt feeders Metso Outotec

Belt feeders' technical specifications Belt width: From 24” up to 72” Maximum capacity: 2628 t/h Maximum speed: 0.3 m/s Maximum lump size: 267 mm (10 1/2”) Belt feeder slope:

Bulk Material Handling Hapman

Conveying, Bag Handling andProcessing Solutions. 1. Tubular Drag Conveyor. Product captured between flights is moved en masse exposing it to very little turbulence during its

Used Belt Feeder Conveyors for Sale Surplus Record

Incline feeder 1.1ft³ stainless steeel hopper mounted 1" above incline conveyor, 5-1/2" wide belt with 1/2" high cleats on 12" centers and flex wall discharging atmore View Details

Belt Feeder Conveyor MiningAggregates IEM

IEM belt conveyor system is extremely versatile conveyor that carries a wide variety of applications such as copper, coal, nickel, salt, limestone and fertilizer. Belt Conveyor Features Open truss Stringer Stringer table

Thayer Scale Bulk Material Handling Systems

Continuous Weighing and Feeding of Bulk Materials since 1949. Thayer Scale is the pioneering developer of continuous weighing and feeding equipment for the dry solids conveying and processing industries. Our

Conveyor Belts McMaster-Carr

Replace worn and broken V-belts on conveyor rollers. Flat Belts Super-Grip Flat Belting Commonly used for material handling and light to medium duty power transmission, this belting has a textured rubber cover on both sides for gripping material. High-Speed Extended-Life Leather Flat Belting

Used Incline/Cleated Equipment — Machine for Sale

FMC Feeder Incline/Cleated BELT CONVEYOR. Manufacturer: FMC Model Number: BELT CONVEYOR Frain Number: 5F2164 6" wide x 96" long, incline neoprene cleated belt conveyor. Equipped with 5" wide x

Bulk Material Handling Hapman

The Tubular Drag Conveyor’s totally enclosed, dust-tight design makes it an obvious candidate for handling and containing dusty, noxious, toxic, or explosive hazardous materials. Learn More Helix ® Flexible Screw Conveyor Vacuum Conveyors Tubular Drag Conveyors Small Bag Compactors Small Bag Dump Stations Bulk Bag Fillers Bulk Bag

Pros and cons of pneumatic and mechanical

2019年5月6日But since pneumatic conveyors require separate receiving equipment at every destination, such as filter receivers, weighing valves or rotary airlock valves, tubular cable conveyors can be the lower cost

6 key considerations for conveyor selection

2017年11月16日For example, while a process may consume 1,000 pounds per hour of material, the conveyor or feeder may need to deliver at a rate that is 12 times higher if the batch needs to be satisfied in five

Zorg Biogas GmbH Catalogue Solid feeders

Solid feeders are used for dosing, chopping and feeding beet pulp, silage, manure, leftover and other solid feedstocks into a biogas reactor. Depending on the type of raw material supply, feeding technology is

Food Conveyors and Washdown Conveyors Ultimation

Food conveyors are the powerhouse of the and beverage processing industry. Food conveyors move s and other organic materials through their processes safely and quickly. All at a fraction of the cost of manual

Belt Feeder Conveyor MiningAggregates IEM

IEM belt conveyor system is extremely versatile conveyor that carries a wide variety of applications such as copper, coal, nickel, salt, limestone and fertilizer. Belt Conveyor Features Open truss Stringer Stringer table

Volumetric Feeders Acrison

Acrison’s Model 170-1-2 and 170-2-2 Volumetric Feeders for dry solids are designed for both continuous and batching applications incorporating a highly versatile metering mechanism featuring two independently driven metering augers for the accurate and reliable feeding over an exceptionally wide feed range. The design of the Model 170-1-2 and

Coperion K-Tron Feeders Coperion

In Coperion K-Tron’s patented Smart Force Transducer (SFT), the signal is directly converted into a digital weight signal by a built-in microprocessor. The signal is then communicated noise-free via RS 485 to the controller.

Handling of Solids Transport and Storage EOLSS

4.3.3 Formation of Solid Bridges 4.3.4 Solutions to Caking Problems Basic Components of a Pneumatic Conveying System 5.3. Screw Feeders and Screw Conveyors 5.3.1. Screw Conveyors 5.3.2. Screw Feeder 5.3.3. Screw Conveyer Feed Rate 5.3.4. Screw Casing in solids handling is also quite unrelated to the capital cost of the equipment

BELT CONVEYOR 911Metallurgist

2021年5月8日Estimated operating maintenance cost per year for a belt conveyor is 2% of the purchase cost plus 5% of the belt cost. Belt replacement is on average every 5 years for hard rock applications and

Pipe Conveyor, Pipe Conveyor System, Pipe Belt Conveyor

The pipe conveyor is a new type of belt conveyor. It is a enclosed curve, suitable for a variety of bulk material transportation systems. thereby reducing the cost of infrastructure and the equipment cost. 2. Curved arrangement of conveying lines in space Max feed size(mm) 30: 30~50: 50~70: 70~90: 90~100: 100~120: 120~150:

Thayer Scale Bulk Material Handling Systems

Thayer Scale is the pioneering developer of continuous weighing and feeding equipment for the dry solids conveying and processing industries. Our equipment provides that rare combination of precision

Conveyor Belts McMaster-Carr

Replace worn and broken V-belts on conveyor rollers. Flat Belts Super-Grip Flat Belting Commonly used for material handling and light to medium duty power transmission, this belting has a textured rubber cover on both sides for gripping material. High-Speed Extended-Life Leather Flat Belting

Used Incline/Cleated Equipment — Machine for Sale

Incline cleated belt feeders are designed feed bulk solid items such as caps or parts. Incline cleated belt feeders are designed with an inclined conveyor belt with cleats which conveys the product up to the

Coperion K-Tron Feeders Coperion

In Coperion K-Tron’s patented Smart Force Transducer (SFT), the signal is directly converted into a digital weight signal by a built-in microprocessor. The signal is then communicated noise-free via RS 485 to the controller.

Conveying Equipment U.S. Conveying Manufacturer

Move It. While most conveyor manufacturers outsource parts production, Superior uses our own ingredients in our conveying equipment. All the idlers, pulleys, scrapers and accessories — basically the operating

Bulk Material Handling Hapman

The Tubular Drag Conveyor’s totally enclosed, dust-tight design makes it an obvious candidate for handling and containing dusty, noxious, toxic, or explosive hazardous materials. Learn More Helix ® Flexible Screw Conveyor Vacuum Conveyors Tubular Drag Conveyors Small Bag Compactors Small Bag Dump Stations Bulk Bag Fillers Bulk Bag

6 key considerations for conveyor selection

2017年11月16日For example, while a process may consume 1,000 pounds per hour of material, the conveyor or feeder may need to deliver at a rate that is 12 times higher if the batch needs to be satisfied in five

Zorg Biogas GmbH Catalogue Solid feeders

Solid feeders are used for dosing, chopping and feeding beet pulp, silage, manure, leftover and other solid feedstocks into a biogas reactor. Depending on the type of raw material supply, feeding technology is

Food Conveyors and Washdown Conveyors Ultimation

Food conveyors are the powerhouse of the and beverage processing industry. Food conveyors move s and other organic materials through their processes safely and quickly. All at a fraction of the cost of manual

Volumetric Feeders Acrison

Acrison’s Model 170-1-2 and 170-2-2 Volumetric Feeders for dry solids are designed for both continuous and batching applications incorporating a highly versatile metering mechanism featuring two independently driven metering augers for the accurate and reliable feeding over an exceptionally wide feed range. The design of the Model 170-1-2 and

BELT CONVEYOR 911Metallurgist

2021年5月8日Estimated operating maintenance cost per year for a belt conveyor is 2% of the purchase cost plus 5% of the belt cost. Belt replacement is on average every 5 years for hard rock applications and

Pipe Conveyor, Pipe Conveyor System, Pipe Belt Conveyor

The pipe conveyor is a new type of belt conveyor. It is a enclosed curve, suitable for a variety of bulk material transportation systems. thereby reducing the cost of infrastructure and the equipment cost. 2. Curved arrangement of conveying lines in space Max feed size(mm) 30: 30~50: 50~70: 70~90: 90~100: 100~120: 120~150:

Cost Comparison Conveyor vs Hauler bulk-online

2004年4月21日A few points are: 1. Civils: a) Cut and Fill for overland, incline or decline conveyors will favor belts beyond 1 km in length. b) Greater the slope (>10%) the more likely the conveyor will beat the truck. Maintenance of roadways can cause significant cost to project. c) Heavy rains impact road design and maintenance.

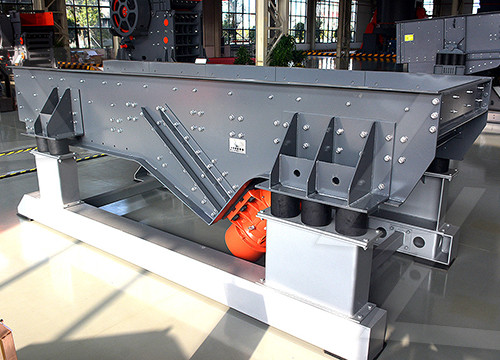

Conveyors / Belt Feeders

DIRECTXPRESS Belt Feeder-Conveyor. 14" belt feeders for single or divided lot operations. 18" belt feeders for multi-lot operations. Direct drive gearbox reduces maintenance. Exclusive Jamesway chain system eliminates the constant adjustment required by cable drive systems. 2-1/2’, 5’ and 10’ 16 gauge galvanized steel sections