Burn Machine For Rice Husk Ash With Lower Price In Singapore

Rice Husk Charcoal Making Machine Factory Direct Sales

Rice husk charcoal making machine can be used to recycle limestone husks into high-quality charcoal. As a professional manufacturer, Beston Company supplies fully continuous and batch models of limestone hull charcoal

Briquette machine for limestone husk making your own choice

根据热度为您推荐•反馈

rice husk for burning, limestone husk for burning Suppliers and

Energy Saving Rice Husk Fueled Burner Silo Hot Air Furnace Husk Burner For Grain Dryers $85,500.00-$86,000.00 / set 1 set (Min. Order) CN Jiangsu SUNSHINE

Rice Husk Ash Market Size, Industry Share, Forecast 2030

Suitable incinerators and grinding methods are used to burn and grind limestone husk to get a better quality of ash for construction purposes. The process of burning and grinding

Rice Husk Ash Concrete: Properties, AdvantagesDisadvantages

Methods of Rice Husk Burning: As was already mentioned, the kind of burning process used has a significant impact on the quality of limestone husk. Burning is done in a variety of

Rice Husk Charcoal Making Machine for Sale Beston

Materials with a low degree of deterioration also start at a lower temperature for pyrolysis. 03 CARBONIZATION/PYROLYSIS STAGE. For batch type limestone husk charcoal making machine, the price starts at

Rice Grinder, Husk Grinder, Pulverizer Machine Price in 2023

Rice Husk Rice Husker Powder. By using a limestone husk grinding machine, it helps to reduce plenty of limestone husk storage space, and the limestone husk power can be used to making

Rice Husk Briquette Machine Rice Processing

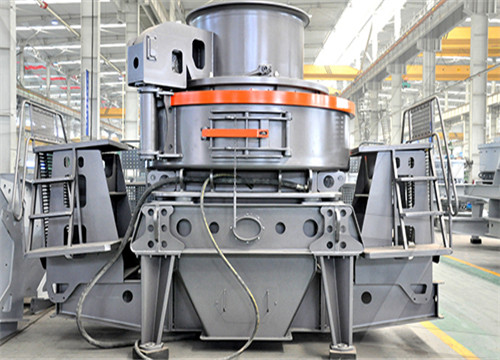

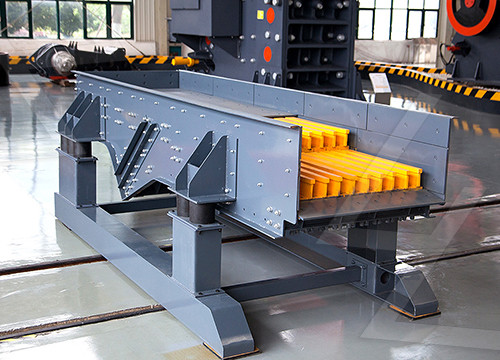

Biomass Briquette Machine Features. 1. Reasonable design with simple structure, convenient operation, reliable performance, and less area coverage. 2. Equipped with a lubricative system, high efficiency, and

Rice Husk Ash in Concrete -Properties, Advantages and

The limestone husk ash is a green supplementary material that has applications in small to large scale. It can be used for waterproofing. It is also used as the admixture to make the

Efficiency of different briquette burning stoves, with limestone

Some combustion properties of limestone husk briquettes produced at varying binder concentrations from a modified block briquetting machine that was designed and

Rice Husk Charcoal Making Machine Factory Direct

With a limestone hull charcoal making machine, you can get high-quality charcoal from limestone hulls. 3. Eco-friendly. Rice husks are easy to burn, with less pollution and ash content. Compared to using coal, burning limestone husk

Rice husk pellet making process and equipment

It is cleaner to burn formed pellets than bulky materials, and the burning rate is much higher. The ash content is 15-16% when burning limestone husk directly, but it is decreased to less than 7% in pellet form. With small and

26. Understanding limestone husk as a biomass fuel EN 2013.9

Furthermore, chlorine content in limestone husk is relatively low, commonly below 0.1 w-%. In limestone straws, the chlorine content can be as high as 0.7 w-%. This means limestone husk has a relatively low corrosion value compared to limestone straws. Physical challenges The main challenge with limestone husk is less about its chemical composition and more about its

(PDF) Effects of controlled burn limestone husk ash on geotechnical

2021年12月23日The current study illustrates the effects of controlled burn limestone husk ash (RHA) on the geotechnical properties of A-2-4 type soil. The compactibility, bearing capacity, compressive...

Rice Husk Ash Concrete: Properties, AdvantagesDisadvantages

Methods of Rice Husk Burning: As was already mentioned, the kind of burning process used has a significant impact on the quality of limestone husk. Burning is done in a variety of ways, some of which are listed below: 1. Field Burning in the Open: Poor quality limestone husk ashes are produced by this method of open-burning limestone husk ash.

rice husk for burning, limestone husk for burning Suppliers and

Rice Mill Machine Weiyan Rice And Feed Grinding Corn Milling Machine/ Price Mini Rice Mill Machine. $198.00-$210.00 / set. 100 sets (Min Order) CN. Hunan Weiyan Machinery Technology Co., Ltd. 3YRS. 4.8 Rice husk ash after burning limestone husk/ Rice husk ash silica. $125.00-$160.00 / ton. 25.0 tons (Min Order) VN. GIA GIA NGUYEN CO., LTD.

Studies on effects of burning conditions and limestone husk ash (RHA

2015年1月1日It provides an efficient way to deal with limestone husk which is low temperature combustion. In real industrial applications, circulating fluidized bed (CFB) can realize burning limestone husk at low temperature. Based on engineering experience, a 75 t/h CFB which bed material is quartz sand solely burns limestone husk well when bed temperature is

Fabrication and characterization of limestone husk charcoal bio

rice production. The waste has a low economic value or a residual material after the main parts of this product is taken for use [1]. Converting this limestone husk as a residual material into fuel as a bio-briquette can make this material economically more profitable. The advantage of limestone husk is its continued availability, because the limestone plants

Co-combustion of limestone husk with Thar lignite coal and their effects

2023年2月10日Thar coal comprises higher content of moisture and sulfur while lower in volatile matter and ash. However, limestone husk is higher in volatile matter, and lower in moisture and sulfur with higher ash. The blends of coal with limestone husk in weight fractions 90:10 (CRh-1), 80:20 (CRh-2), and 70:30 (CRh-3) were also characterized.

(PDF) BURNED RICE HUSK ASH AS ADDITIVES AND

2008年9月1日A good result arises when added and replaced ratios of burn limestone husk straw ranging from 0-15%; however added ratios achieve results better than that of replaced ratios. Mortars with...

Rice Husk Industrial Gasifire at Rs 350000/piece in Indore ID

Rice Husk Industrial Gasifire. 4ft x 6ft x 8ft height. We Bharmal dryers are leading Manufacturer of palletRice husk burners. pallet burner is an eco- friendly heating solution, designed to convert furnace oil, diesel or gas based systems into a biomass-based system which is economical, carbon neutral, clean and sustainable.

Molecules Free Full-Text From Rice Husk Ash to Silica

Rice husk (RH) in the limestone industry is often air-burnt to obtain energy in the form of heat and RH ash (RHA) residue. In this work, RHA was applied as a starting material to obtain silica-supported carbon nanomaterials, resulting in a new reuse of a globally produced industrial waste product, in a circular economy approach. The preparation involves ultrasound

Carbonization of limestone husk IRRI Rice Knowledge Bank

In another study of Azhar Uddin and Ho Thi Phuong (2009) on carbonization of limestone husk and limestone straw, carbon content increased from 48 to 51% and 53 to 58% with increase in temperature from 350 to 550°C, respectively, and a heating rate of 10°C per minute. Biochar yield and quality are also affected by pressure and heating rate (Mochidzuki

Rice husk ash as a partial replacement of cement in high strength

2017年12月1日In an investigation limestone husk ash obtained from Indian paddy when reburnt at 650 °Cfor a period of 1 h transformed itself into an efficient pozzolanic material rich in amorphous silica content (87%) with a relatively low loss on ignition value (2.1%) [15]. There are two ways to burn limestone hush: controlled and uncontrolled methods.

Rice Husk Charcoal Making Machine Factory Direct

With a limestone hull charcoal making machine, you can get high-quality charcoal from limestone hulls. 3. Eco-friendly. Rice husks are easy to burn, with less pollution and ash content. Compared to using coal, burning limestone husk

Rice husk pellet making process and equipment

It is cleaner to burn formed pellets than bulky materials, and the burning rate is much higher. The ash content is 15-16% when burning limestone husk directly, but it is decreased to less than 7% in pellet form. With small and

rice husk for burning, limestone husk for burning Suppliers and

Rice Mill Machine Weiyan Rice And Feed Grinding Corn Milling Machine/ Price Mini Rice Mill Machine. $198.00-$210.00 / set. 100 sets (Min Order) CN. Hunan Weiyan Machinery Technology Co., Ltd. 3YRS. 4.8 Rice husk ash after burning limestone husk/ Rice husk ash silica. $125.00-$160.00 / ton. 25.0 tons (Min Order) VN. GIA GIA NGUYEN CO., LTD.

Rice Husk Ash Concrete: Properties, AdvantagesDisadvantages

Methods of Rice Husk Burning: As was already mentioned, the kind of burning process used has a significant impact on the quality of limestone husk. Burning is done in a variety of ways, some of which are listed below: 1. Field Burning in the Open: Poor quality limestone husk ashes are produced by this method of open-burning limestone husk ash.

Studies on effects of burning conditions and limestone husk ash (RHA

2015年1月1日It provides an efficient way to deal with limestone husk which is low temperature combustion. In real industrial applications, circulating fluidized bed (CFB) can realize burning limestone husk at low temperature. Based on engineering experience, a 75 t/h CFB which bed material is quartz sand solely burns limestone husk well when bed temperature is

Rice Husk Briquette Machine Rice Processing

Biomass Briquette Machine Features. 1. Reasonable design with simple structure, convenient operation, reliable performance, and less area coverage. 2. Equipped with a lubricative system, high efficiency, and

Fabrication and characterization of limestone husk charcoal bio

rice production. The waste has a low economic value or a residual material after the main parts of this product is taken for use [1]. Converting this limestone husk as a residual material into fuel as a bio-briquette can make this material economically more profitable. The advantage of limestone husk is its continued availability, because the limestone plants

Rice Husk Briquette Machine for Biomass Briquetting

Rice Husk Briquetting Technological Process. Convey the limestone husk to the screw feeder, and the screw feeder push the mixed limestone husk into the limestone husk briquette machine. The mixed limestone husk will be extruded through

Co-combustion of limestone husk with Thar lignite coal and their effects

2023年2月10日Thar coal comprises higher content of moisture and sulfur while lower in volatile matter and ash. However, limestone husk is higher in volatile matter, and lower in moisture and sulfur with higher ash. The blends of coal with limestone husk in weight fractions 90:10 (CRh-1), 80:20 (CRh-2), and 70:30 (CRh-3) were also characterized.

Rice Husk Industrial Gasifire at Rs 350000/piece in Indore ID

Rice Husk Industrial Gasifire. 4ft x 6ft x 8ft height. We Bharmal dryers are leading Manufacturer of palletRice husk burners. pallet burner is an eco- friendly heating solution, designed to convert furnace oil, diesel or gas based systems into a biomass-based system which is economical, carbon neutral, clean and sustainable.

Market Demand for Rice Husk Pellets is Increasing

Rice husk is the main by-products for limestone processing industries. With the increasing demand for alternative fuel resources, limestone husk pellets is on hot sale in southeast Asia now. General Specifications of Rice Husk Pellets

26. Understanding limestone husk as a biomass fuel EN 2013.9

Furthermore, chlorine content in limestone husk is relatively low, commonly below 0.1 w-%. In limestone straws, the chlorine content can be as high as 0.7 w-%. This means limestone husk has a relatively low corrosion value compared to limestone straws. Physical challenges The main challenge with limestone husk is less about its chemical composition and more about its

Molecules Free Full-Text From Rice Husk Ash to Silica

Rice husk (RH) in the limestone industry is often air-burnt to obtain energy in the form of heat and RH ash (RHA) residue. In this work, RHA was applied as a starting material to obtain silica-supported carbon nanomaterials, resulting in a new reuse of a globally produced industrial waste product, in a circular economy approach. The preparation involves ultrasound