Fine Jaw Crusher Cge Jaw Crusher Specifications Jaw Crusher Plant

® C Series™ jaw crushers Proven reliability

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher

Industrial Solutions Jaw crushers ThyssenKrupp

• high fines content CSS jaw opening [mm] EB 12-10 N EB 14-11 N EB 16-12 N EB 20-15 N Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10%

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

Scott Rocklabs BIG BOYD

The BOYD Crusher is the world’s first double-acting, fine jaw crusher. Its design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass. The Big BOYD Crusher takes lump

Jaw Crushers Parker Plant

High capacity 'Rocksizer' or 'RockSledger' Jaw crusher Improved high performance manganese jaws Heavy duty feeder with grizzly section Diesel hydraulic drive, all electric or electro-hydraulic Wide discharge

Crushing Products Size and Shape -What to Expect

2016年2月26日The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Additionally, jaw crusher feed should be pre-screened using a grizzly screen prior to crushing to remove material finer than the closed-side setting. Setting jaw

Pioneer® Jaw Crushers Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the

HSE Quarries Safe operation and use of mobile jaw

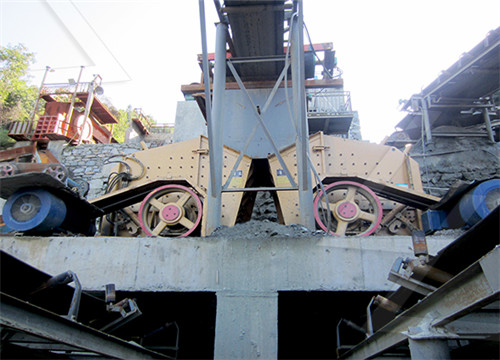

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for

Fine Jaw Crushers

The fine jaw crusher range includes: Essa® JC1250 Fine Jaw Crusher the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to

Industrial Solutions Jaw crushers ThyssenKrupp

• high fines content CSS jaw opening [mm] EB 12-10 N EB 14-11 N EB 16-12 N EB 20-15 N Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con -

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary

Scott Rocklabs BIG BOYD

The BOYD Crusher is the world’s first double-acting, fine jaw crusher. Its design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass. The Big BOYD Crusher takes lump

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日The operation of the fine crushing plant is independent, to a large degree, of the performance of the primary crusher. A great deal of thought has been given to the problem of attaining maximum efficiency in

Jaw Crusher Crushing Plant Hard Rock Mining

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1,000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse

Jaw Crusher Primary Crusher in MiningAggregate

Product Introduction. JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of medium-hard materials to smaller physical size. Jaw rock crushers are capable of

Hard Rock Gold Crusher Crushing Diesel Engine Mobile Type PE

Jaw crusher can be used as the primary crusher to the medium size crushing of various ores and large-size materials,with the anti-crushing pressure of less than 350Mpa.And the jaw crusher can be divided into two kinds such as coarse and fine crushing .And this series of jaw crusher have complete specifications with the feeding particle size

Jaw Crusher Specification-China Jaw Crusher Specification

Jaw Crusher Specification s Mining or Construction US $ 3,500-7,800 / Set 1 Set (MOQ) More Stone Crusher, Stone Grinder Mill, Sand Making Plant Mining Machine, Stone Production Line, Sand Production Line, Mining Machine, Grinding Mill, Crushing Equipment, Stone Making Machine, Grinder Audited Supplier Zhengzhou General Mining Machinery

sbmchina/sbm impact crusher capacity 100tph specifiions.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Rock Crushers, Stone Crushers, Screening and

jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton. Stationary HSI impact crushers Horizontal Shaft Impact

HSE Quarries Safe operation and use of mobile jaw crushers

The movement of any material present inside the crusher Slipping and falling Manual handling of rocks and equipment Unexpected movement of crusher components Damaged electrical cable Noise...

Jaw Crusher Plant Stone CrushingScreening Plant for Sale

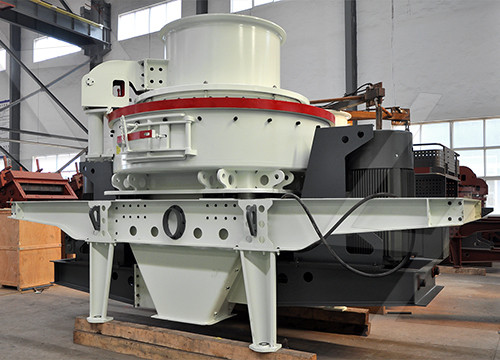

Features of jaw crusher plant 1.Big crushing ratio 2.Uniform products size 3.Easy maintenance 4.Long useful lifetime Application of jaw crusher plant It is widely used in the recycling of mines, coal mines, garbage and construction wastes, earth and stone works, urban infrastructure, roads or construction sites.

Jaw Crushers Heavy Duty Finlay

LJ-130 Hybrid. The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The machine features a robust 1300 x 1000mm (51

Industrial Solutions Jaw crushers ThyssenKrupp

• high fines content CSS jaw opening [mm] EB 12-10 N EB 14-11 N EB 16-12 N EB 20-15 N Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con -

Scott Rocklabs BIG BOYD

The BOYD Crusher is the world’s first double-acting, fine jaw crusher. Its design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass. The Big BOYD Crusher takes lump

Jaw Crushers MEKA CrushingScreening Plants

JAW CRUSHER Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained, which means that we must provide secondary

Estimate Jaw Crusher Capacity Mineral Processing

2016年2月17日Estimate Jaw Crusher Capacity jaw crusher production capacity Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (2.8 SG) e = 0.2 (halfway between dolomite and sandstone) A

Jaw Crusher Crushing Plant Hard Rock Mining

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1,000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse

HSE Quarries Safe operation and use of mobile jaw crushers

The movement of any material present inside the crusher Slipping and falling Manual handling of rocks and equipment Unexpected movement of crusher components Damaged electrical cable Noise...

Jaw Crusher Primary Crusher in MiningAggregate

Jaw crushers are supplied in sizes up to 1,600 mm (gape)×1,900 mm (width). For coarse crushing application (closed set~300 mm), capacities range up to 1200 tph. Jaw Crusher Wear Parts Jaw crusher parts must

Hard Rock Gold Crusher Crushing Diesel Engine Mobile Type PE

Jaw crusher can be used as the primary crusher to the medium size crushing of various ores and large-size materials,with the anti-crushing pressure of less than 350Mpa.And the jaw crusher can be divided into two kinds such as coarse and fine crushing .And this series of jaw crusher have complete specifications with the feeding particle size

sbmchina/sbm impact crusher capacity 100tph specifiions.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Jaw Crushers Heavy Duty Finlay

LJ-130 Hybrid. The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The machine features a robust 1300 x 1000mm (51

Rock Crushers, Stone Crushers, Screening and Crushing

jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton. Stationary HSI impact crushers Horizontal Shaft Impact crushers can be configured to operate in a variety of applications, either as a primary crusher or in secondary crushing mode.

Jaw Crusher Plants ELRUS Aggregate Equipment

Jaw Crushers. Jaw Crushers are used extensively throughout the world by the aggregate, mining and recycle industries. Their large physical size and rectangular feed opening enable them to receive a larger feed size than most other types of crushers. Rugged construction, simplicity of design and the ability to crush most types of material, including hard