Impact Crusher Belgium

IMPACT CRUSHERS

Our impact crushers. PRIMARY IMPACT CRUSHER HPI. With throughput rates up to 2,500 t/h, HPI Primary Impactors are used extensively in the cement,

进一步探索

Spare parts APS Secondary Impactor Hazemag North America根据热度为您推荐•反馈

Impact Crushers

impact crushers are designed to excel as primary impactors, taking large feed material and reducing it down to a sellable product. They’re also extremely suitable

Crushers Keestrack

Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications. Key benefits Superior product shape Highest reduction ratio Ability to track while

ARJA Impact Crushers for Belgian Limestone ARJA

ARJA Impact Crushers for Belgian Limestone The French monthly magazine “MinesCarrières” is dedicated to presenting the sector's technical innovations. It is aimed at

Impact Crushers Heavy Duty Finlay

Impact Crushers Finlay® offer a comprehensive range of Mobile Impact Crushers that excel in quarrying, mining, demolition and recycling applications. Combined with our after

Impact crushers high-quality impactors Metso Outotec

Impact crushers can be used in all different stages of size reduction from primary crushing to the last step of the crushing process. Contact our sales experts High performance

Choosing a mobile impact crusher for recycling what

2021年3月12日Mobile impact crushers, also known as the tracked impact crusher or recycling impactor, are recognizable mainly due to the fact that these crushers are

RM 120X Mobile Impactor Crush Different RUBBLE

The crusher box features a 3-stage single-apron impact wall for fast and easy adjustment of your closed side setting. You deserve not only great mobile impactor but also the

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush on

MEKA CrushingScreening and Concrete Batching

MEKA brings you a wide range of feeders, crushers, screens and washing systems that can be designed as a full complete stationary or mobile solution/complex according to the location, type of rock and individual

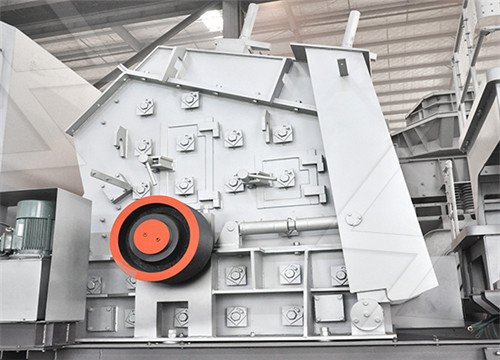

MEKA PRIMARY IMPACT CRUSHER HAS BEEN

2023年2月15日MEKA MPI 1313 Primary Impact Crusher has arrived in Belgium for our customer and the installation has been started MEKA Primary impact crushers are preferred for their high performance and

Stationary HSI Impact Crushers, Horizontal Impact

The modularization within our horizontal impact crushers ensures you have the same size bearings and shaft diameter used between models. This is consciously done to reduce stockholding and the costs involved.

Impact Crushers

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio. Impactors are often used as a cost effective alternative to jaw and cone combination plants as

Crushers Keestrack

Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications. Key benefits Superior product shape Highest reduction ratio Ability to track while

Impact Crushers Heavy Duty Finlay

Impact Crushers Finlay® offer a comprehensive range of Mobile Impact Crushers that excel in quarrying, mining, demolition and recycling applications. Combined with our after sales support the Finlay range of Impact Crushers can take your operation to the next level. Sign Up For More Info

Strong and reliable hammer impact crusher I

Our EV Hammer Impact Crusher, however, competently reduces quarry-size limestone boulders measuring up to 2.5 metres and weighing up to 5 tonnes to mill feed of 25 millimetres. This is a reduction ratio of 1:100 in a

I-140RS Impact Crushing Machine Horizontal

The Finlay® I-140RS is an Impact Crushing Machine. This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production capabilities in quarrying,

ARJA Impact Crushers for Belgian Limestone ARJA

And specifically in last month's issue, number 263, our brand ARJA was specially mentioned for its ICR- T Piscis 2000E impact crusher, owned by “la Carrière des Limites “ in Rochefort and its ICR- S Tauro 30E impact crusher owned by “la Carrière Berthe” in Florennes, both of which are located in Belgium.

Impact crushers high-quality impactors Metso Outotec

Impact crushers can be used in all different stages of size reduction from primary crushing to the last step of the crushing process. Contact our sales experts High performance High reduction ration. Good quality end products. Reduced plant operating costs Durable wear parts and mechanical components. Configured for your needs

Mobile Crusher Rental: Concrete, Asphalt, Rock RUBBLE MASTER

JawImpact Crushers From low volume concrete and asphalt recycling to high-volume custom crushingquarrying RUBBLE MASTER has the right size mobile crusher for you. Capacity Inlet opening Transport dimension Weight RM MXJ1100 Jaw Crusher 385 TPH 43" x 27" 47'11" x 9'10" x 11'9" 110,231 lbs learn more RM 120X Impact Crusher 385

Keestrack

Reversible Impact I Series I4e. Impact R Series Impact R Series R3. R5. R5e. R6. Cone H Series Cone H Series H4e. H6e. H6Se ZERO. H7e ZERO. Screens. Scalper K Series Scalper K Series K3. K4. K5. K6. K7. K8. Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications.

Impact crusher parts Metso Outotec

Metso Outotec’s impact crusher spare parts are known for ease of maintenance and reliability. They enable better process control and a stable production pace when processing rock, sand, gravel or recycled materials. Main components Frames Rotor Common component Automation capable Automatic lubrication Parts fastening kit

Impact Crusher Eastman Rock Crusher

Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Applications widely utilized in aggregate, mining, energy, brick and so on industrial applications, depending to the type of an impact crusher, they can be used as a primary, secondary, or tertiary crushers to meet final-product-size needs.

MEKA CrushingScreening and Concrete Batching

MEKA brings you a wide range of feeders, crushers, screens and washing systems that can be designed as a full complete stationary or mobile solution/complex according to the location, type of rock and individual

MEKA PRIMARY IMPACT CRUSHER HAS BEEN

2023年2月15日MEKA MPI 1313 Primary Impact Crusher has arrived in Belgium for our customer and the installation has been started MEKA Primary impact crushers are preferred for their high performance and

Stationary HSI Impact Crushers, Horizontal Impact

The modularization within our horizontal impact crushers ensures you have the same size bearings and shaft diameter used between models. This is consciously done to reduce stockholding and the costs involved.

Keestrack

Reversible Impact I Series I4e. Impact R Series Impact R Series R3. R5. R5e. R6. Cone H Series Cone H Series H4e. H6e. H6Se ZERO. H7e ZERO. Screens. Scalper K Series Scalper K Series K3. K4. K5. K6. K7. K8. Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications.

Impact Crushers

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio. Impactors are often used as a cost effective alternative to jaw and cone combination plants as

ARJA Impact Crushers for Belgian Limestone ARJA

And specifically in last month's issue, number 263, our brand ARJA was specially mentioned for its ICR- T Piscis 2000E impact crusher, owned by “la Carrière des Limites “ in Rochefort and its ICR- S Tauro 30E impact crusher owned by “la Carrière Berthe” in Florennes, both of which are located in Belgium.

Strong and reliable hammer impact crusher I

Our EV Hammer Impact Crusher, however, competently reduces quarry-size limestone boulders measuring up to 2.5 metres and weighing up to 5 tonnes to mill feed of 25 millimetres. This is a reduction ratio of 1:100 in a

Crushing and sizing technology for all stages

Crushing and sizing. Robust. Reliable. Crushing and sizing equipment that’s up to the task. The demands on your crushing and sizing equipment are extreme. Crunching up rock without breaking teeth. Reducing sticky and

I-140RS Impact Crushing Machine Horizontal

Impact Crusher The Finlay® I-140RS is an Impact Crushing Machine. This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production

ImpactCement Crusher Manufacturer Stedman Machine

An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers: Horizontal shaft impactors (HSI) Cage mill pulverizers

I-120RS Horizontal Shaft Impact Crusher Finlay

The Finlay® I-120RS shapes the future through innovation. This new generation Horizontal Shaft Impact Crusher with redefined style and advanced technological design gives improved material flow and

Impact crusher parts Metso Outotec

Metso Outotec’s impact crusher spare parts are known for ease of maintenance and reliability. They enable better process control and a stable production pace when processing rock, sand, gravel or recycled materials. Main components Frames Rotor Common component Automation capable Automatic lubrication Parts fastening kit

Impact Crusher Eastman Rock Crusher

Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Applications widely utilized in aggregate, mining, energy, brick and so on industrial applications, depending to the type of an impact crusher, they can be used as a primary, secondary, or tertiary crushers to meet final-product-size needs.

Impact Crushers For Sale Ritchie Bros. Auctioneers

An impact crusher is a stone pulverizer machine that strikes materials, such as cement, rock, minerals, etc., to pulverize it and to create a finished product. Buying an impact crusher is a cost-efficient alternative to impact crusher rental or buying new.