Brief Description About The Process Of Iron Ore Crushing And Grinding

The six main steps of iron ore processing Multotec

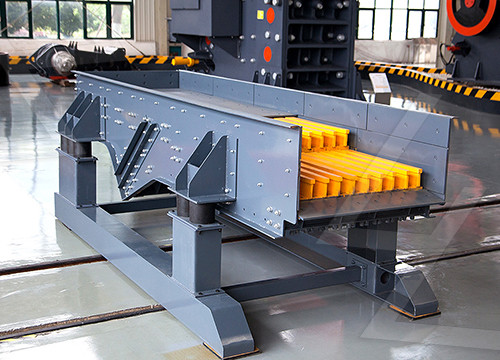

Screening. We recommend that you begin by screening the iron ore to separate fine

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used,

进一步探索

Different Types of Iron Ore Mineral ProcessingMetallurgyTypes of Iron Ore: Hematite vs. Magnetite INN根据热度为您推荐•反馈

(PDF) Research into the crushing and grinding processes

2019年1月1日PDF Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high Find, read

11.24 Metallic Minerals Processing US EPA

11.24.1 Process Description1-6 Metallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the

Crushing, Grinding and Concentration of the Ore Class

2023年2月16日The process of metallurgy depends upon the nature of the ore and the impurities present in it. Some common steps involved in the metallurgical operations are :

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After

What is the crushing process? MEKA

What is the crushing process? Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In

What is iron ore crushing and processing? Quora

Iron ore is an important raw material of steel producers.After crushing, grinding, magnetic separation, flotation, re-election and other procedures,natural minerals (iron ore)elected

Brief description about the processing of iron ore

2012年9月20日Each of these types of crushing equipment are designed for use in specific situations involving the processing of iron ore. For example, hammer crushers

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat. Before being delivered to the sinter machine, the ore mixture is

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable

Grinding Circuit an overview ScienceDirect Topics

The circuit comprises a SAG mill, 12 m diameter by 6.1 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones. The SAG mill is fitted with a 20 MW gearless drive motor with bi-directional rotational capacity.

(PDF) Research into the crushing and grinding

2019年1月1日PDF Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high Find, read and cite all the research you

11.24 Metallic Minerals Processing US EPA

11.24.1 Process Description1-6 Metallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing

Crushing, Grinding and Concentration of the Ore

2023年2月16日The process of metallurgy depends upon the nature of the ore and the impurities present in it. Some common steps involved in the metallurgical operations are : 1) Crushing and grinding of the ore 2)

Processing of Magnetite Iron Ores–Comparing

2009年1月1日The importance of comminution test works originates from the high level of energy consumed in the processing chain to grind the ore to achieve a desirable particle size, liberation, and high...

What is iron ore crushing and processing? Quora

Iron ore is an important raw material of steel producers.After crushing, grinding, magnetic separation, flotation, re-election and other procedures,natural minerals (iron ore)elected gradually of iron. Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impurities.

Brief description about the processing of iron ore

2012年9月20日Each of these types of crushing equipment are designed for use in specific situations involving the processing of iron ore. For example, hammer crushers are often used at mine sites when the yield from iron ore deposits is somewhat small. After use of some form. of crushing equipment, the processing of iron ore will usually involve

P process of making pig iron in a blast furnace using pellets

2018年6月19日The iron ore and coke can be loaded into the blast furnace from the top in alternate layers, and hot air is fed from tuyeres at the base of the furnace into the furnace to generate carbon monoxide gas from the coke. The heat of this reaction and the carbon monoxide are being used to reduce and melt the iron ore. The pig iron and slag thus

Eco-efficient and cost-effective process design for magnetite iron ore

2015年2月24日Option 4 is an attempt to design a circuit with the lowest operating cost through increased grinding energy efficiency using three stages of magnetic separation, traditional autogenous milling, HPGR and stirred milling technology. In this conceptual flowsheet, steel grinding media is eliminated.

What is the crushing process? MEKA

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing". Although there is no limit set, the downsizing process over 3 mm is considered as "crushing

Minerals Free Full-Text Economic and Socio-Environmental

2020年10月26日In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energy-efficient technologies for dry processing of magnetite ores. The present study investigates the economic and socio-environmental benefits of applying these technologies in conceptual

USB2 Iron ore concentration process with grinding

In one embodiment, the invention provides an iron ore concentration process with grinding circuit, dry desliming and dry concentration, wherein the process comprises the steps of: crushing an ore; dry grinding of the ore crushed in step a); dry desliming of the ore grinded in step b); and magnetically separating the ore deslimed in step c), resulting in a

Iron processing Ores Britannica

Crushing As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size.

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable

Grinding Circuit an overview ScienceDirect Topics

The circuit comprises a SAG mill, 12 m diameter by 6.1 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones. The SAG mill is fitted with a 20 MW gearless drive motor with bi-directional rotational capacity.

(PDF) Research into the crushing and grinding

2019年1月1日PDF Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high Find, read and cite all the research you

Crushing and Grinding Process JXSC Machine

2019年10月8日The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the

Crushing, Grinding and Concentration of the Ore

2023年2月16日The process of metallurgy depends upon the nature of the ore and the impurities present in it. Some common steps involved in the metallurgical operations are : 1) Crushing and grinding of the ore 2)

Processing of Magnetite Iron Ores–Comparing

2009年1月1日The importance of comminution test works originates from the high level of energy consumed in the processing chain to grind the ore to achieve a desirable particle size, liberation, and high...

Eco-efficient and cost-effective process design for magnetite iron ore

2015年2月24日Option 4 is an attempt to design a circuit with the lowest operating cost through increased grinding energy efficiency using three stages of magnetic separation, traditional autogenous milling, HPGR and stirred milling technology. In this conceptual flowsheet, steel grinding media is eliminated.

Brief description about the processing of iron ore

2012年9月20日Each of these types of crushing equipment are designed for use in specific situations involving the processing of iron ore. For example, hammer crushers are often used at mine sites when the yield from iron ore deposits is somewhat small. After use of some form. of crushing equipment, the processing of iron ore will usually involve

P process of making pig iron in a blast furnace using pellets

2018年6月19日The iron ore and coke can be loaded into the blast furnace from the top in alternate layers, and hot air is fed from tuyeres at the base of the furnace into the furnace to generate carbon monoxide gas from the coke. The heat of this reaction and the carbon monoxide are being used to reduce and melt the iron ore. The pig iron and slag thus

Minerals Free Full-Text Economic and Socio-Environmental

2020年10月26日In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energy-efficient technologies for dry processing of magnetite ores. The present study investigates the economic and socio-environmental benefits of applying these technologies in conceptual

What is the crushing process? MEKA

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing". Although there is no limit set, the downsizing process over 3 mm is considered as "crushing

Sustainability Free Full-Text A Brief Note on the Heap Leaching

Heap leaching is a low-cost technology used in industrial mining to recover precious metals such as gold and uranium, along with several other highly sought after metals like copper, from their primary resources (ores and minerals). For many decades, there has been a growing demand for heap leaching due to its environmental benefits. Heap leaching

mpl Iron ore grinding plant for ores milling process unisbm

Grinding is a powdering or pulverizing process using the rock mechanical forces of impaction, compression, shearing and attrition. Main machines in ore grinding process are Iron ore mill equipment. The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill. The selection of is according to customers