Production Cost Of Limeore Grinding Plant

11.17 Lime Manufacturing US EPA

manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln

Daswell Lime Calcination Plant Turnkey Solutions for

Daswell machinery offers tailored solutions for quicklime production plant, including designing, planning and providing lime processing machinery. Different plant sizes

limestone grinding plant

After ultra-fine grinding, high-quality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, , rubber and other products.

How much does it cost to invest in a limestone grinding

How much does it cost to invest in a limestone grinding production line with a daily output of 100 tons Time: 2022-08-19 The limestone production line is composed of a variety

Cost of Mini Limestone Grinding Machine Manufacturing

Model NO.: LM130 LM370 Type: Raymond Mill Motor Type: AC Motor Motor Power: 185 2240kw Rotationl Speed: Different Application: Applications: Cement, Coal, Power Plant

How Much Does It Cost To Start A Cement Plant?

2020年5月14日According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an

Reducing Cost of Production in Cement Plant LinkedIn

2019年11月20日d) Grinding power savings can be realized by using appropriate additives to replace clinker (Ex Limestone, Pozzolonas, Fly Ash etc) will result into energy savings

production cost for limeore mining spxlearningcenter

limeore mining production plant cost Limestone Crushing Production CostGalactic Spacebook. Oct 12, 2020 Limestone is the raw material with a large amount of cement

Lime processing plant setup cost MiningQuarry Plant

2013年3月19日TENTATIVE COST OF SETTING UP A STONE QUARRY PLANT in south africa Choose Quality Lime Processing Plant 1 Set FOB Price: US $60000

Turnkey Solutions for Limestone Processing Plant Daswell

Daswell limestone processing plants, be the limestone grinding plant, limestone calcining plant or lime hydration plant, are designed and delivered according to customers’ needs, such as properties of raw materials, production capacity, end product quality, applications, and so on.

11.17 Lime Manufacturing US EPA

manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined,

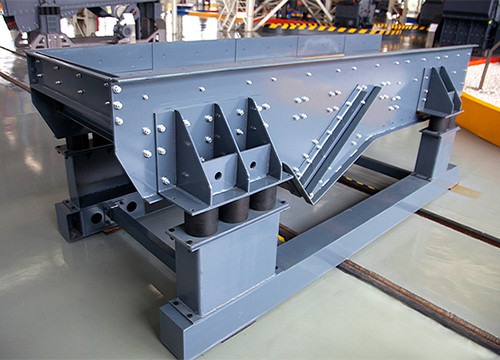

11.19.2 Crushed Stone Processing and Pulverized Mineral

5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional crushing and screening operations is subject to coarse and fine grinding primarily in roller mills and/or

Quicklime Plant Turnkey Solutions for Limestone Processing Plant

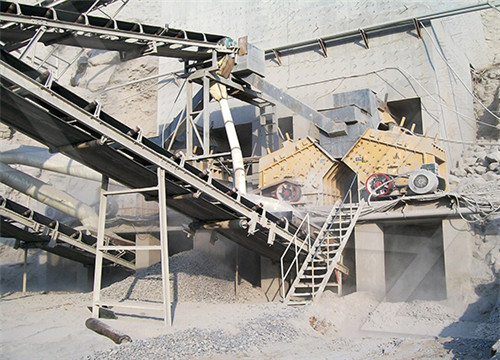

The quicklime calcination plant includes many sectors to process limestone so as to get quicklime. Generally, there are crushing process, conveying process, preheating process, calcining process, cooling process, de-dusting and packing process. Firstly, quarried limestone will be crushed in primary and secondary crushers to obtain required

How Much Does It Cost To Start A Cement Plant?

2020年5月14日According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone

Cement Plant Cement Manufacturing Plant EPC Project

The raw materials grinding power consumption takes 30%, cement grinding power consumption takes 40%, other parts takes 30%, it is important to choose cement grinding mill to keep cement quality and reduce energy consumption. Recommended solution to cement manufacturing plants Why Choose AGICO Cement Manufacturing Plant?

Lime processing plant setup cost MiningQuarry Plant

2013年3月19日TENTATIVE COST OF SETTING UP A STONE QUARRY PLANT in south africa Choose Quality Lime Processing Plant 1 Set FOB Price: US $60000-300000 / Set. Category: Uncategorized ? Dolomite processing plant setup cost Limestone processing plant setup cost ? Get price and support, find the working site in your

sbm/sbm limeore mining machine ore plant reclamation.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

production cost for limeore mining spxlearningcenter

limeore mining production plant cost Limestone Crushing Production CostGalactic Spacebook. Oct 12, 2020 Limestone is the raw material with a large amount of cement production. After mining, it has larger particle size and higher hardness, so it needs to be broken by limestone crushing plant, themonly used limestone crushing equipment

Nigeria Limestone and Plaster Processing Plant sbmchina

The whole limestone processing plant includes the crushing machine, grinding mill and beneficiation equipment. In Nigeria limestone processing plant, you need to have a good understanding of these processing machines and the whole production line. Raw limestone materials will be sent into jaw crusher for primary crushing through vibrating

Cement Production an overview ScienceDirect Topics

Production Planning Using Day-Ahead Prices in a Cement Plant. Turgay Emir, Mehmet Güray Güler, in Exergetic, Energetic and Environmental Dimensions, 2018. Abstract. Cement production is an energy-intensive process. The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider minimizing

Understanding How The Indian Cement Industry Works

Cement is basically is made by heating limestone (calcium carbonate) with small quantities of other materials to 1450°C in a kiln. The resultant hard material which is recovered after heating limestone and chemicals is called ‘Clinker’. Clinker looks like small lumps.

Cement clinker Wikipedia

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay

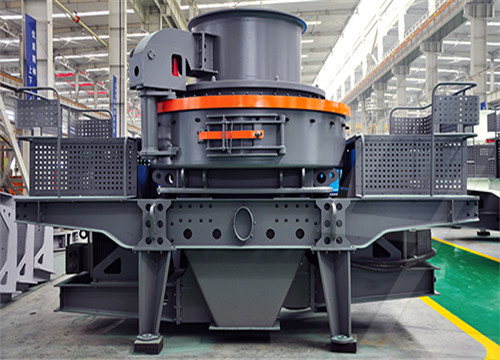

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc..

11.17 Lime Manufacturing US EPA

manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined,

Turnkey Solutions for Limestone Processing Plant Daswell

Limestone grinding plant is a production line to grind limestone in limestone grinding mills to obtain fine limestone powder, Daswell modern rotary lime kiln often includes vertical preheater and vertical cooler to improve production efficiency and reduce costs. Daswell limestone calcining plant are also customized designed to meet

11.19.2 Crushed Stone Processing and Pulverized Mineral

5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional crushing and screening operations is subject to coarse and fine grinding primarily in roller mills and/or

Quicklime Plant Turnkey Solutions for Limestone Processing Plant

The quicklime calcination plant includes many sectors to process limestone so as to get quicklime. Generally, there are crushing process, conveying process, preheating process, calcining process, cooling process, de-dusting and packing process. Firstly, quarried limestone will be crushed in primary and secondary crushers to obtain required

How Much Does It Cost To Start A Cement Plant?

2020年5月14日According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone

Nigeria Limestone and Plaster Processing Plant sbmchina

The whole limestone processing plant includes the crushing machine, grinding mill and beneficiation equipment. In Nigeria limestone processing plant, you need to have a good understanding of these processing machines and the whole production line. Raw limestone materials will be sent into jaw crusher for primary crushing through vibrating

Lime processing plant setup cost MiningQuarry Plant

2013年3月19日TENTATIVE COST OF SETTING UP A STONE QUARRY PLANT in south africa Choose Quality Lime Processing Plant 1 Set FOB Price: US $60000-300000 / Set. Category: Uncategorized ? Dolomite processing plant setup cost Limestone processing plant setup cost ? Get price and support, find the working site in your

sbm/sbm limeore mining machine ore plant reclamation.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

production cost for limeore mining spxlearningcenter

limeore mining production plant cost Limestone Crushing Production CostGalactic Spacebook. Oct 12, 2020 Limestone is the raw material with a large amount of cement production. After mining, it has larger particle size and higher hardness, so it needs to be broken by limestone crushing plant, themonly used limestone crushing equipment

Cement Production an overview ScienceDirect Topics

Today ‘s annual global cement production has reached 2.8 billion tonnes, and is expected to increase to some 4 billion tonnes per year in 2050 ( Schneider et al., 2011 ). Major growth is foreseen in countries such as China and India as well as in regions like the Middle East and Northern Africa.

Must-know: The cost elements of cement Market Realist

2014年8月18日The primary raw material that’s used is limestone. Raw materials account for 30%–40% of the cost of sales. Cement plants are generally located near limestone quarries because limestone...

Understanding How The Indian Cement Industry Works

Cement is basically is made by heating limestone (calcium carbonate) with small quantities of other materials to 1450°C in a kiln. The resultant hard material which is recovered after heating limestone and chemicals is called ‘Clinker’. Clinker looks like small lumps.

Cement clinker Wikipedia

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc..