Process Of Making Mining Mill Machine

Milling Process Definition,Milling Manufacturing Processes

The milling machine involves the following processes or phases of cutting: Milling Cutters There are a lot of cutting tools used in the milling

Stamp mill Wikipedia

OverviewDescriptionHistoryOther stamping millsSee alsoBibliographyExternal links

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a type of unit operation.

Milling, What is it and how does it work? Dassault

Milling is a Substractive machining process that uses many machine toolsets to efficiently precision-cut a variety of materials (such as metals,

Dry milling machines Schenck Process

Our largest and strongest products include dry and wet milling machines that grind hard, abrasive materials for applications like mineral processing, cement plants, and power

Milling Machine Definition, ProcessTypes Engineering

The milling machine involves the following processes or phases of cutting: Milling Cutters There are a lot of cutting tools used in the milling process. The milling cutters named end mills have special cutting surfaces on

CNC Milling a Complete Guide to Understand the

2020年5月8日The milling process includes: Designing the parts in CAD Translating the CAD files into code for machining Setting up the machinery Producing the parts Designing the CAD filestranslation into code The

Workshop report on milling machine and process.

2022年3月15日A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to remove material from a

Milling CuttersTools Types and Their Purposes (with

2020年2月21日Milling Cutters and Tools an Overview. CNC machining is a highly utilised subtractive manufacturing technology. Computer numerical control systems offer less need for manpower and higher

What is milling and what is the purpose? Voortman

In standard processes, the drilling machine will pre-drill a hole in which the mill will be lowered. It will then clear the hole up to the required diameter. Slotted holes In a slotted hole, the diameter of the radii of the two ends of

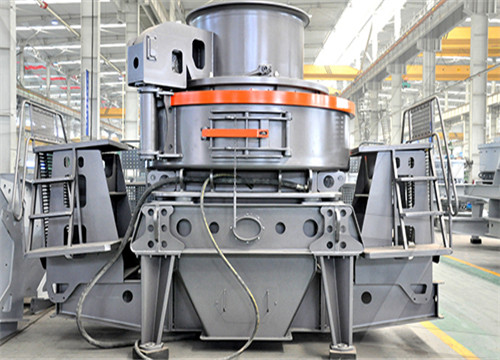

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Jaw crushers are heavy duty machines and can be used in mining or quarry applications for very hard materials. Jaw crusher. Ball mills use a tumbling process with stone or metal balls as the grinding

How Ball Mills Work (Engineering and Mining) YouTube

2019年6月20日How Ball Mills Work (Engineering and Mining) YouTube 0:00 / 15:29 How Ball Mills Work (Engineering and Mining) saVRee 193K subscribers Join Subscribe 2.8K Share 193K views

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which

Milling Process, Defects, Equipment CustomPart.Net

8. Cost Drivers. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling

How milling machine worksit's advantages CUBII

2021年11月6日The milling machine allowed a less skilled operator to make the same quality of parts as the skilled operator with the file. The CNC (tape) machines started to show up around 1953, in the earlier past the

Milling CuttersTools Types and Their Purposes

2020年2月21日Milling Cutters and Tools an Overview. CNC machining is a highly utilised subtractive manufacturing technology. Computer numerical control systems offer less need for manpower and higher

3 Effective Methods for Tramming a Milling Machine

2020年2月4日5. Lower your quill until the tip of the DTI touches the parallel/table and zero it. 6. Swing the spindle 180 degrees and check the reading on the opposite side of the axis. 7. If the readings are the same,

Boring on Mill University of Florida

Bridgeport milling machines have three choices for quill automatic quill feedrate: 0.001, 0.003, and 0.006 in/rev. The middle speed typically works well for most work. The following schematic and accompanying video

What is milling and what is the purpose? Voortman

In standard processes, the drilling machine will pre-drill a hole in which the mill will be lowered. It will then clear the hole up to the required diameter. Slotted holes In a slotted hole, the diameter of the radii of the two ends of

Top 6 Applications of Machine Learning in Process Mining in ’23

2021年10月1日Diagnostic process mining. Diagnostic process mining refers to process diagnostics method to: Analyze issues to find the root causes. Classify problems into categories. Capture the trend in process change over time. Diagnostic processes are applied to find a problem in a process. For example, in delivery systems, diagnostic

Different Types of Machining Operations and the Machining Process

1 Some of the operations a milling machine is capable of performing include planing, cutting, rabbeting, routing, die-sinking, and so on, making the milling machine one of the more flexible pieces of equipment in a machine shop. There are four types of milling machines hand milling machines, plain milling machines, universal milling

Milling holes and cavities/ pockets Coromant

Reduce corner feed. 2. Circular milling (2-axes) large ap. Drill a hole, and then change to a shoulder end mill or a long edge cutter. A typical application area is found in aerospace framing titanium machining. Application hints. Ensure good chip evacuation to prevent re-cutting of chips/chip jamming:

CNC Milling a Complete Guide to Understand the

2020年5月8日The milling process includes: Designing the parts in CAD Translating the CAD files into code for machining Setting up the machinery Producing the parts Designing the CAD filestranslation into code The

Milling (machining) Wikipedia

The milling process removes material by performing many separate, small cuts. This is accomplished by using a cutter with many teeth, spinning the cutter at high speed, or advancing the material through the cutter slowly;

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Jaw crushers are heavy duty machines and can be used in mining or quarry applications for very hard materials. Jaw crusher. Ball mills use a tumbling process with stone or metal balls as the grinding

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which

Milling Process, Defects, Equipment CustomPart.Net

8. Cost Drivers. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling

How milling machine worksit's advantages CUBII

2021年11月6日The milling machine allowed a less skilled operator to make the same quality of parts as the skilled operator with the file. The CNC (tape) machines started to show up around 1953, in the earlier past the

Milling CuttersTools Types and Their Purposes

2020年2月21日One of these automated fabrication methods is CNC milling. It is a process where rotary cutters remove material, which makes it the opposite of CNC turning. The milling centres do not just perform

3 Effective Methods for Tramming a Milling Machine

2020年2月4日To tram your machine using a spindle square, follow these simple steps: 1. Insert the spindle square in the collet 2. Lower the quill until the two indicators are touching the tabletop 3. Check that the readings

Boring on Mill University of Florida

Bridgeport milling machines have three choices for quill automatic quill feedrate: 0.001, 0.003, and 0.006 in/rev. The middle speed typically works well for most work. The following schematic and accompanying video

What is milling and what is the purpose? Voortman

In standard processes, the drilling machine will pre-drill a hole in which the mill will be lowered. It will then clear the hole up to the required diameter. Slotted holes In a slotted hole, the diameter of the radii of the two ends of

What Is The Milling Process? The Whittling Guide

2022年1月5日The milling process uses cutting tools rotating at set speeds. Bring the cutting tools with the workpiece to start removing materials when they come with the workpiece. Milling removes crevices from the surfaces of metals that cause corrosion. It gets rid of excess material off the surface of a workpiece. The process prepares metals

Top 6 Applications of Machine Learning in Process Mining in ’23

2021年10月1日Diagnostic process mining. Diagnostic process mining refers to process diagnostics method to: Analyze issues to find the root causes. Classify problems into categories. Capture the trend in process change over time. Diagnostic processes are applied to find a problem in a process. For example, in delivery systems, diagnostic

Different Types of Machining Operations and the Machining Process

1 Some of the operations a milling machine is capable of performing include planing, cutting, rabbeting, routing, die-sinking, and so on, making the milling machine one of the more flexible pieces of equipment in a machine shop. There are four types of milling machines hand milling machines, plain milling machines, universal milling

Milling holes and cavities/ pockets Coromant

Drill a hole, and then change to a shoulder end mill or a long edge cutter. A typical application area is found in aerospace framing titanium machining. Application hints Ensure good chip evacuation to prevent re-cutting of chips/chip jamming: Horizontal spindle (ISO 50) is preferred

CNC Milling a Complete Guide to Understand the

2020年5月8日The milling process includes: Designing the parts in CAD Translating the CAD files into code for machining Setting up the machinery Producing the parts Designing the CAD filestranslation into code The