Outline The Steps Of Manufacturing Portland Cement

11.6 Portland Cement Manufacturing epa.gov

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic The initial production step in portland cement manufacturing is raw materials acquisition.

Manufacture of Portland Cement- Materials and Process The

The manufacture procedures of Portland cement is described below. Mixing of raw material Burning Grinding Storage and packaging 1. Mixing

How Cement Is Made

根据热度为您推荐•反馈

11.6 Portland Cement Manufacturing US EPA

1971年8月17日11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

Manufacturing of Portland Cement Process and Materials

What Is Cement Made of?Wet ProcessDry ProcessFor the bulk and continuous manufacturing and production of Portland Cement following mineral materials are used: calcareous materials (limestone or chalk), argillaceous material (shale or clay), blast furnace slag, silica sand, iron ore, and gypsum as raw material.Cement factories are established where these ra在cementconcrete上查看更多信息评论数: 3

Cement manufacturing process: Step-by-step guide

2020年7月20日This articles looks at the cement manufacturing process in 4 steps. Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other

Stages of the Portland cement process production

The production process of the Portland cement is presented in Fig.1. The clinker, base component of the Portland cement, is obtained from the grinding, homogenization and subsequent burn in high

How Portland Cement is Made? Manufacturing Process of

2009年8月31日Manufacturing Portland Cement The basic ingredients of both the dry and wet processes are the same. By mass, lime and silica make up approximately 85% of portland cement. The materials that are

Portland Cement Manufacturing Industry: National

2022年8月15日Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone,

Cement Extraction and processing Britannica

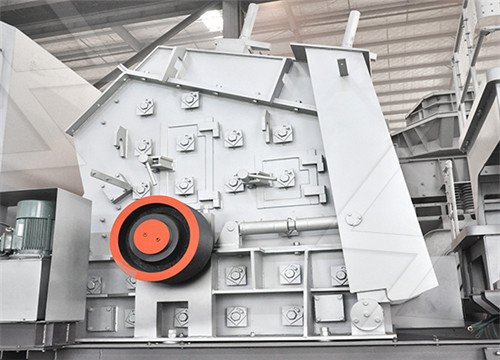

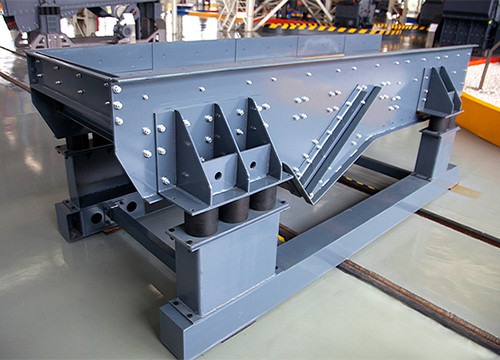

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the

11.6 Portland Cement Manufacturing epa.gov

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic The initial production step in portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in portland cement, is obtained from a

How Cement Is Made

Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum,

Cement manufacturing process: Step-by-step guide

2020年7月20日This articles looks at the cement manufacturing process in 4 steps. Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other

Stages of the Portland cement process production

The production process of the Portland cement is presented in Fig.1. The clinker, base component of the Portland cement, is obtained from the grinding, homogenization and subsequent burn in high

11.6 Portland Cement Manufacturing US EPA

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the pyroprocessing operation. Raw material preparation includes a variety of blending and sizing

OPC Cement Types of OPC, 4 Manufacturing Steps

2020年5月10日Manufacturing of OPC Cement: There are four steps in the manufacturing process of OPC cement as given below; Crushing and Grinding of Raw Material Mixing or Blending Heating Grinding. Crushing

New approach suggests path to emissions-free cement

2019年9月16日Caption: In a demonstration of the basic chemical reactions used in the new process, electrolysis takes place in neutral water. Dyes show how acid (pink) and base (purple) are produced at the

Concrete and Concrete Products Overview

Safety issues exist in all phases of concrete production, including the manufacture of portland cement and pre-cast concrete products, as well as during the use of concrete in construction. This page was developed

Portland Cement Manufacturing Industry: National Emission US EPA

2022年8月15日Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln. The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materials.

Cement Extraction and processing Britannica

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the

Portland Cement: What is it? Uses, History and Types Becosan

2021年7月15日6 Manufacturing phases of Portland Cement 6.1 1. Obtaining raw materials 6.2 2. Classification and preparation of raw materials 6.3 3. Homogenization 6.4 4. Clinkerization 6.5 5. Cooling 6.6 6. Incorporation of final aggregates and milling 7 Conclusions on our Portland Cement article 8 References What is Portland Cement?

Portland cement Britannica

2023年2月23日portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and shale. The inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a

Processes Free Full-Text Evaluation of the Quality of the Cement

2023年3月7日Portland cement is produced by finely grinding clinker and gypsum. It achieves a high strength and is produced without the addition of blast furnace slag. An Ishikawa diagram is a diagram that shows the causes of an event which is often used in manufacturing and product development to outline the different steps in a process,

11.6 Portland Cement Manufacturing epa.gov

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic The initial production step in portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in portland cement, is obtained from a

How Cement Is Made

The most common way to manufacture portland cement is through a dry method. The first step is to quarry the principal raw materials, mainly limestone, clay, and other materials. After quarrying the rock is crushed.

Cement Extraction and processing Britannica

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the

Stages of the Portland cement process production

The production process of the Portland cement is presented in Fig.1. The clinker, base component of the Portland cement, is obtained from the grinding, homogenization and subsequent burn in high

How Cement is Made Cement Manufacturing Process

Stage of Cement Manufacture There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite.

Portland Cement Manufacturing Ordinary

Portland Cement Manufacturing Process. Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding,

New approach suggests path to emissions-free cement

2019年9月16日Caption: In a demonstration of the basic chemical reactions used in the new process, electrolysis takes place in neutral water. Dyes show how acid (pink) and base (purple) are produced at the

Portland cement Britannica

2023年2月23日portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and shale. The inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a

Ordinary Portland Cement -Constituents,

Advantages of Ordinary Portland Cement. It has great resistance to cracking and shrinkage but has less resistance to chemical attacks. Initial setting time of OPC is faster than PPC so it is recommended in projects

Portland Cement Manufacturing Process SystemsDesign Blog

2017年9月5日The final step in portland cement manufacturing involves a sequence of blending and grinding operations that transforms clinker to finished portland cement. Up to 5 percent gypsum or natural anhydrite is added to the clinker during grinding to control the cement setting time, and other specialty chemicals are added as needed to impart

Emission Factor Documentation for AP-42 Portland

The portland cement manufacturing industry is dispersed geographically throughout the United States, with 36 States having at least one plant. The initial production step in portland cement manufacturing is raw materials acquisition. More than 30 raw materials are known to be used to manufacture portland cement. Calcium, the element of

Processes Free Full-Text Evaluation of the Quality of the Cement

2023年3月7日Portland cement is produced by finely grinding clinker and gypsum. It achieves a high strength and is produced without the addition of blast furnace slag. An Ishikawa diagram is a diagram that shows the causes of an event which is often used in manufacturing and product development to outline the different steps in a process,