Stone Mining Mill Dust As Fine Aggregate In Concrete Pav

Stone crusher dust as a fine aggregate in Concrete for

2010年9月1日From the outcome of numerous experimentations, it has been observed that stone dust can be partially replaced up to 40%-50% without compromising the

An Experimental study on Crushed Stone Dust as Fine

2018年1月1日(ii) Crushed Stone dust is a fine material formed during the process of conversion of rock into aggregate and has particle size ranging from 4 mm to dust size

Stone dust as fine aggregate in concrete: Effects on

concrete and Quarry Stone dust concrete. The strength achieved in concrete made with sand as fine aggregate achieved high strengths when compared with Quarry stone

Stone Dust in Concrete: Effect on Compressive Strength

2015年8月1日Stone dust is a waste material obtained from crusher plants. It has potential to be used as partial replacement of natural river

Utilization of Stone Dust as Fine Aggregate Replacement in

of fine aggregate with stone dust. The results shows strength of concrete increases within 5-12 percent up to 50 percent replacement of fine aggregate. And at 60 percent stone

What is the Percentage of Stone Dust that can be added along

2020年6月2日For M20 grade, 25% is the optimum percentage of stone dust mix with the concrete. 30% of stone dust requires relative high cement content. If 50% replacement

The Utilization of Quarry Dust as Fine Aggregates in Concrete

concluded that the compressive strength of concrete, with 50% Sand and 50% quarry dust (Mix 3), under thermo shock and high temperature showed the least reduction in

Stone Dust Braen Stone

Stone dust is often referred to as screenings, however they are one and the same. Stone dust is a fine layer of pulverized stone. Screenings can be used for many different

Environmental Impacts of Aggregate and Stone Mining

A related impact from aggregate and stone mining is increased traffic congestion and safety hazards in both small rural communities and urban areas. Unlike metals or coal

Influence of brick dust, stone dust, and recycled fine aggregate

2020年8月12日The present stone study the effect of partial substitution of brick dust (BD), stone dust (SD), and recycled fine aggregate (RFA) as fine aggregate on the properties of natural aggregate concrete (NAC) and recycled aggregate concrete (RAC). 4.67–34.67%, respectively, when the replacement of NFA with BD and SD in both NAC

Development of sustainable concrete using silica fume and stone dust

2020年1月1日The 30% replacement of fine aggregates with stone dust resulted in an increase of compressive and flexural strength by 2.32% and 3.03%, respectively, to control mix. The addition of grade II stone dust in the normal concrete having fine aggregates representing zone III has made concrete denser as compared to control mix. The 40%

USE OF STONE DUST AS AN ALTERNATIVE FINE AGGREGATE MATERIAL IN CONCRETE

2022年1月20日The present research's aim is to find out the optimum percentage of stone dust while designing a mix of an M20 grade of concrete .The sand is replaced by stone dust by 10%, 15% and 20%.

Stone Dust as Fine Aggregate Replacement in

2015年4月1日Stone dust is such an alternative material which can be effectively being used in construction as partial replacement of natural sand. Hence present study taken a view to verify the suitability...

Utilization of Stone Dust as Fine Aggregate Replacement in

of fine aggregate with stone dust. The results shows strength of concrete increases within 5-12 percent up to 50 percent replacement of fine aggregate. And at 60 percent stone dust in concrete the maximum value of compressive strength is obtained which is 17 percent more than referral concrete (concrete with zero percent stone dust).

What is the Percentage of Stone Dust that can be added along with Fine

2020年6月2日For M20 grade, 25% is the optimum percentage of stone dust mix with the concrete. 30% of stone dust requires relative high cement content. If 50% replacement of sand 450 kg per meter cube cement needed to achieve the target means strength for M25 grade. Also, the increase in water-cement ratio didn’t yield a positive result.

Fine aggregate: Understanding its role in concrete

2023年2月22日Crushed gravel and crushed stone can also fall under this category. Role of fine aggregate in a concrete mix. The majority of the volume in the formulations for making a concrete mix is taken up by fine

Stone Dust Braen Stone

Stone dust is often referred to as screenings, however they are one and the same. Stone dust is a fine layer of pulverized stone. Screenings can be used for many different projects and applications. Request a Quote Material Details Material Usage Downloads Primarily used in hot mix asphalt.

Quarry limestone dust as fine aggregate for concrete IOPscience

2018年4月10日Quarry limestone dust as fine aggregate for concrete. Liborio Cavaleri 1, Ruben Paul Borg 2, F. P. La Mantia 1 and Vincenzo Liguori 1. Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 442, FIB Conference: Sustainable Concrete: Materials and Structures 10 April 2018, Malta

Stone Dust: What It Is, Uses, and Where to Buy It The

2022年6月21日You can buy stone dust at most stone yards and quarries. Some excavation companies also sell it, along with the crushed stone, sand, gravel, bricks, flagstones, etc. that you might need for

11.19.1 Sand And Gravel Processing US EPA

11/95 Sand And Gravel Processing 11.19.1-1 11.19.1 Sand And Gravel Processing 11.19.1.1 Process Description1-6 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in near-surface alluvial deposits and in subterranean and subaqueous beds.

DIVISION II MATERIALS Virginia Department of

and IM-19.0E asphalt concrete shall consist of crushed stone, crushed slag, or crushed gravel and fine aggregate, slag or stone screenings or a combination thereof combined with asphalt cement. NOTE: At the discretion of the Engineer, an intermediate mix may be designated as either a SM-19.0A or SM-19.0D. For SM-

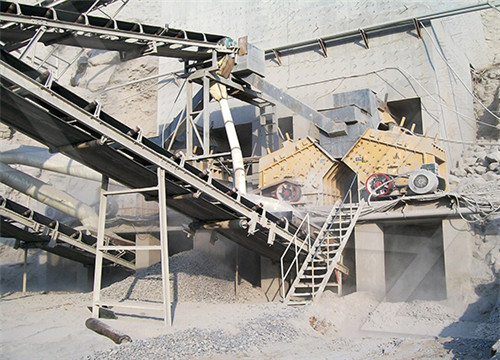

11.19.2 Crushed Stone Processing and Pulverized Mineral

Emissions of PM, PM-10, and PM-2.5 occur from a number of operations in stone quarrying and processing. A substantial portion of these emissions consists of heavy particles that may settle out within the plant. As in other operations, crushed stone emission sources may be categorized as either process sources or fugitive dust sources.

The Effect of Aggregate Properties on Concrete Penn State

Aggregate is classified as two different types, coarse and fine. Coarse aggregate is usually greater than 4.75 mm (retained on a No. 4 sieve), while fine aggregate is less than 4.75 mm (passing the No. 4 sieve). The compressive aggregate strength is an important factor in the selection of aggregate.

Influence of brick dust, stone dust, and recycled fine aggregate

2020年8月12日The present stone study the effect of partial substitution of brick dust (BD), stone dust (SD), and recycled fine aggregate (RFA) as fine aggregate on the properties of natural aggregate concrete (NAC) and recycled aggregate concrete (RAC). 4.67–34.67%, respectively, when the replacement of NFA with BD and SD in both NAC

Development of sustainable concrete using silica fume and stone dust

2020年1月1日The 30% replacement of fine aggregates with stone dust resulted in an increase of compressive and flexural strength by 2.32% and 3.03%, respectively, to control mix. The addition of grade II stone dust in the normal concrete having fine aggregates representing zone III has made concrete denser as compared to control mix. The 40%

USE OF STONE DUST AS AN ALTERNATIVE FINE AGGREGATE MATERIAL IN CONCRETE

2022年1月20日The present research's aim is to find out the optimum percentage of stone dust while designing a mix of an M20 grade of concrete .The sand is replaced by stone dust by 10%, 15% and 20%.

Quarry limestone dust as fine aggregate for concrete IOPscience

2018年4月10日Quarry limestone dust as fine aggregate for concrete. Liborio Cavaleri 1, Ruben Paul Borg 2, F. P. La Mantia 1 and Vincenzo Liguori 1. Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 442, FIB Conference: Sustainable Concrete: Materials and Structures 10 April 2018, Malta

Utilization of Stone Dust as Fine Aggregate Replacement in

of fine aggregate with stone dust. The results shows strength of concrete increases within 5-12 percent up to 50 percent replacement of fine aggregate. And at 60 percent stone dust in concrete the maximum value of compressive strength is obtained which is 17 percent more than referral concrete (concrete with zero percent stone dust).

What is the Percentage of Stone Dust that can be added along with Fine

2020年6月2日For M20 grade, 25% is the optimum percentage of stone dust mix with the concrete. 30% of stone dust requires relative high cement content. If 50% replacement of sand 450 kg per meter cube cement needed to achieve the target means strength for M25 grade. Also, the increase in water-cement ratio didn’t yield a positive result.

11.19.2 Crushed Stone Processing and Pulverized Mineral

Emissions of PM, PM-10, and PM-2.5 occur from a number of operations in stone quarrying and processing. A substantial portion of these emissions consists of heavy particles that may settle out within the plant. As in other operations, crushed stone emission sources may be categorized as either process sources or fugitive dust sources.

Fine aggregate: Understanding its role in concrete mix design

2023年2月22日The size of fine aggregate is defined as equal to or less than 4.75 mm. This means that the aggregates that can pass through a number 4 sieve with a mesh size of 4.75 mm are referred to as fine aggregates. These include clay, silt, and sand. Crushed gravel and crushed stone can also fall under this category. Role of fine aggregate in a

11.19.1 Sand And Gravel Processing US EPA

11/95 Sand And Gravel Processing 11.19.1-1 11.19.1 Sand And Gravel Processing 11.19.1.1 Process Description1-6 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in near-surface alluvial deposits and in subterranean and subaqueous beds.

Stone Dust Braen Stone

Downloads. Primarily used in hot mix asphalt. Stone dust is commonly found in horse stalls and stables as it provides an efficient final base layer. Stone dust is also extremely beneficial as a final base material under patios, walkways and other pathways.

Stone Dust: What It Is, Uses, and Where to Buy It The Spruce

2022年6月21日You can buy stone dust at most stone yards and quarries. Some excavation companies also sell it, along with the crushed stone, sand, gravel, bricks, flagstones, etc. that you might need for other projects. For a fee, most of these places will deliver the product to your property.

Study on Compressive Strength of Quarry Dust as Fine Aggregate in Concrete

2016年7月28日The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries. By replacement of quarry dust, the requirement of land fill area can be reduced and can also solve the problem of natural sand scarcity. The availability of sand at low

DIVISION II MATERIALS Virginia Department of

and IM-19.0E asphalt concrete shall consist of crushed stone, crushed slag, or crushed gravel and fine aggregate, slag or stone screenings or a combination thereof combined with asphalt cement. NOTE: At the discretion of the Engineer, an intermediate mix may be designated as either a SM-19.0A or SM-19.0D. For SM-

The Effect of Aggregate Properties on Concrete Penn State

that defines the concrete’s thermal and elastic properties anddimensional stability. Aggregate is classified as two different types, coarse and fine. Coarse aggregate is usually greater than 4.75 mm (retained on a No. 4 sieve), while fine aggregate is less than 4.75 mm