Build Concrete Crushing Plant

Developers seek rezoning to build concrete crushing plant in Nine

2022年10月4日Developers seek rezoning to build concrete crushing plant in Nine Mile Point Opposition mounts among west bank residents ahead of Planning Advisory Board

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日The crushing process depends on the pressing forces created by movable front jaw and fixed rear jaw, which can separate the concrete from the steel bar and

进一步探索

Concrete Crusher Turn Waste Aggregate Into Useful MateHog Crusher Skid Steer Concrete Crusher EZ Grout根据热度为您推荐•反馈

Concrete Crusher Plant S&L Materials, Inc.

CONCRETE CRUSHER PLANT The S&L Crusher Plant proudly offers a versatile lineup of crushed stone products to meet the aggregate needs of any project. Our production

How to build a concrete batching plant Construction

2021年8月2日A Concrete Batching Plant is a piece of machinery that manufactures concrete. Concrete consists of sand, aggregate, cement, water and add-mixtures. The

Part of the infrastructure ConstructionDemolition Recycling

Plus, the influence of a large equipment buyer could help boost the recycling-related product development plans of crushing and screening technology providers. Positive attention.

You don't want to live near a concrete batch plant. But

2020年8月11日August 11th, 2020. There are at least 188 concrete batch plants in Harris County, more than any other county in Texas. Photo: Allyn West. By Allyn West. “Literally,” Texas state representative Armando

Concrete Crusher Turn Waste Aggregate Into Useful

In the concrete aggregate processing line, the work of the portable concrete crusher for sale in crushing. The aggregate produced by the crusher machine can be used to produce concrete, brick, and so on;

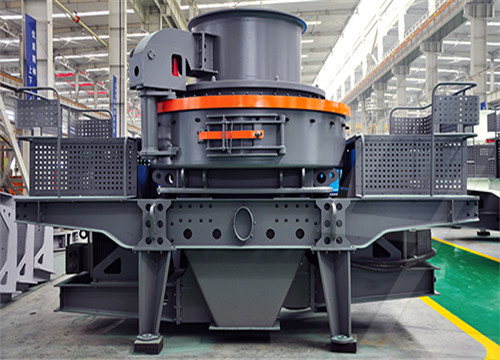

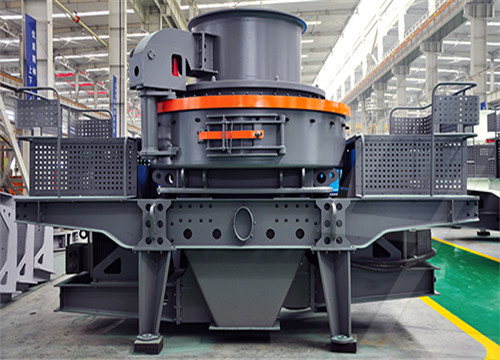

Concrete Crushing Plant Aimix CrusherScreening

Working Process Of Aimix Concrete Crushing Plant: Aimix® can supply primary crushers, secondary crushers to tertiary crushers, and fineness crushing equipment. Concrete aggregate collected from demolition

FactSheet Occupational Safety and Health Administration

Crushing Machines Using crushing machines at construction sites to reduce the size of large rocks, concrete, or construction rubble can generate respirable crystalline silica

How to Build a Rock Crusher Home Guides SF Gate

2017年7月21日1. Using your tape measure and permanent marker, measure and mark the center of the iron board. 2. Center the 4-inch diameter pipe on the mark. 3. Activate your arc welding torch, don you welder's...

How to build a concrete batching plant Construction Review

2022年5月24日The Volumetric Batching Plant. The volumetric batching plant used gates to measure the quantities. The material is passed through a gate at a given speed. The mixer is normally a screw and the concrete is manufactured in a continuous process. At the same time, volumetric batching is accurate to +- 3%. Due to the measuring method, it is

Crusher Aggregate Equipment For Sale

2 之Crusher Aggregate Equipment Price: USD $149,500 Get Financing* Machine Location: Polk City, Florida 33868 View Rental Prices Serial Number: JO200-571D Condition: Used Stock Number: 21K11075

United States Environmental Protection Agency General

1. Concrete Batch Plant Source Category Definition A concrete batch plant is an operation that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate (rocks, gravel, etc.), fly ash, potash, and cement. There are two types of concrete batch plants: ready mix plants and central mix plants.

Aggregate Crushing Plant AIMIX Group

According to the actual demand, the crushing plant can be combined into coarse, fine and two-stage crushing screening system, or it can be combined into coarse, medium and fine three-stage crushing screening

Environmental GUIDELINE ON STONE CRUSHING plant

usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering. A stone crushing plant set up temporarily for the purposes of a project by a public department does not warrant a Preliminary Environmental Report

Mobile Crushing and Screening Plant / Rebel Crusher processing Concrete

2019年5月23日Mobile Crushing and Screening Plant / Rebel Crusher processing Concrete RREquipment 1.72K subscribers Subscribe 18K views 3 years ago This new install shows the Rebel

Concrete Crusher Turn Waste Aggregate Into Useful

In the concrete aggregate processing line, the work of the portable concrete crusher for sale in crushing. The aggregate produced by the crusher machine can be used to produce concrete, brick, and so on;

How Much Does a Concrete Batch Plant Cost From

Generally, stationary concrete batching plant is suitable for large-scale projects, the mobile concrete plant is well fit for small and medium-sized construction, so choosing a suitable concrete plant, which will help you

FactSheet Occupational Safety and Health Administration

Crushing Machines Using crushing machines at construction sites to reduce the size of large rocks, concrete, or construction rubble can generate respirable crystalline silica dust. When inhaled, the small particles of silica can irreversibly damage the lungs. This fact sheet describes dust controls that can be used to minimize the amount of

Crusher Plant MineralAggregate Processing

Crusher plant features 1. Automatic operation. There is hardly any need of manual operation except for start-up, shutdown, and routine maintenance. 2. High production efficiency at low cost, uniform particle size, and good

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Crushing concrete in British Columbia Processing a concrete pile with a RM 80GO! (now a RM 90GO!) mobile crusher in an open circuit configuration. The crusher produces a 3"- fill product. Ideal for Onsite Concrete Crushing Many mobile crushers are heavy and burdensome to mobilize between jobs.

Stormwater Best Management Practices: Concrete Washout

with concrete washwater can percolate down through the soil and alter the soil chemistry, inhibit plant growth, and contaminate the groundwater. Its high pH can increase the toxicity of other substances in the surface waters and soils. Figures 1 and 2 illustrate the need for better washout management practices. Best Management Practice Objectives

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts: SandVik Mining + Metso and Quarry Academy = all agree. The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Crushing concrete in British Columbia Processing a concrete pile with a RM 80GO! (now a RM 90GO!) mobile crusher in an open circuit configuration. The crusher produces a 3"- fill product. Ideal for Onsite Concrete Crushing Many mobile crushers are heavy and burdensome to mobilize between jobs.

How to build a concrete batching plant Construction Review

2022年5月24日The Volumetric Batching Plant. The volumetric batching plant used gates to measure the quantities. The material is passed through a gate at a given speed. The mixer is normally a screw and the concrete is manufactured in a continuous process. At the same time, volumetric batching is accurate to +- 3%. Due to the measuring method, it is

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

United States Environmental Protection Agency General

1. Concrete Batch Plant Source Category Definition A concrete batch plant is an operation that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate (rocks, gravel, etc.), fly ash, potash, and cement. There are two types of concrete batch plants: ready mix plants and central mix plants.

Environmental GUIDELINE ON STONE CRUSHING plant

usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering. A stone crushing plant set up temporarily for the purposes of a project by a public department does not warrant a Preliminary Environmental Report

Concrete Crusher Turn Waste Aggregate Into Useful

In the concrete aggregate processing line, the work of the portable concrete crusher for sale in crushing. The aggregate produced by the crusher machine can be used to produce concrete, brick, and so on;

Mobile Crushing and Screening Plant / Rebel Crusher processing Concrete

2019年5月23日Mobile Crushing and Screening Plant / Rebel Crusher processing Concrete RREquipment 1.72K subscribers Subscribe 18K views 3 years ago This new install shows the Rebel

How Much Does a Concrete Batch Plant Cost From

Generally, stationary concrete batching plant is suitable for large-scale projects, the mobile concrete plant is well fit for small and medium-sized construction, so choosing a suitable concrete plant, which will help you

FactSheet Occupational Safety and Health Administration

Crushing Machines Using crushing machines at construction sites to reduce the size of large rocks, concrete, or construction rubble can generate respirable crystalline silica dust. When inhaled, the small particles of silica can irreversibly damage the lungs. This fact sheet describes dust controls that can be used to minimize the amount of

Stormwater Best Management Practices: Concrete Washout

with concrete washwater can percolate down through the soil and alter the soil chemistry, inhibit plant growth, and contaminate the groundwater. Its high pH can increase the toxicity of other substances in the surface waters and soils. Figures 1 and 2 illustrate the need for better washout management practices. Best Management Practice Objectives

Detroit shoots down proposal for potentially

2022年12月21日The city of Detroit is preventing a controversial concrete crushing plant from opening in a predominantly Black and lower-income neighborhood on the west side.

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts: SandVik Mining + Metso and Quarry Academy = all agree. The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight

CrushingScreening Plants MEKA

Screens are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material types, MEKA screens provide screening efficiency that is high quality and dependable. More Information.

10 Types of Stone Crusher Plants Price and More for Sale

The most common application of crushed stone and rock is to make concrete, which greatly affects the strength of concrete. The stone crusher plant can provide coarse aggregate for infrastructure construction industries such as expressways, high-speed railways, ports, airports, nuclear power, commercial and residential buildings, so it has a