Clasification Of Crushing And Grinding Machines

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific

14 Types of Grinding Machines [Working, DiagramPDF] The

预计阅读时间:7 分钟

Grinding Machine: Types, Parts, WorkingOperations

2023年3月2日A tool and cutter grinder makes use of a CNC machine tool with up to 5 axes and multiple grinding wheels. These devices are used for sharpening and producing milling cutters such as drills, endmills, and

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日Crushing and grinding ar e the two primary A crusher is a machine designed to reduce larg e rocks The objective of this

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw

Crushing and Grinding Process JXSC Machine

2019年10月8日The principle of mineral grinding-classification processing is to combine grinding and classification operation, cleans out the gangue minerals in time, reduces the grinding volume and improves

3 Important Indicators In Grinding And Classification

2020年2月24日To increase the output of grinding machine, we can reduce the grain size of the grinding machine and remove the surrounding rock and rock in advance. That is

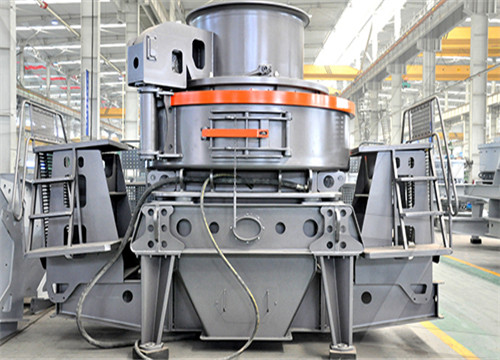

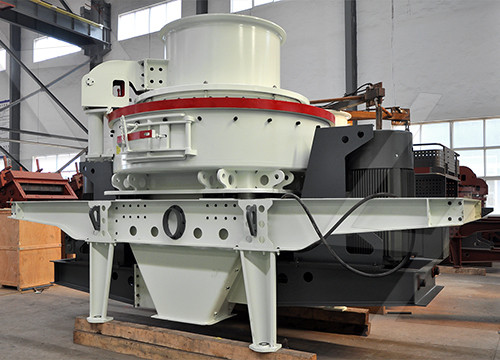

The Classification of Crushing and Grinding Machine

2015年12月1日According to the requirement of crushing granularity, the crushing machine can be divided into coarse crusher, medium crusher and fine crusher By

HS Code 847420- Tariff Classification of Crushing or grinding

Looking for HS codes? Use Flexport's free Search tool to find the tariff code to correctly classify your goods for customs.

Crushers an overview ScienceDirect Topics

They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact. A jaw crusher consists essentially of two crushing plates, inclined to each other forming a

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

14 Types of Grinding Machines [Working, Diagram

2021年11月23日Following are the types of grinding machines: Bench grinding machine Hand grinding machine Pedestal grinding machine Portable grinding machine Flexible grinding machine Precision

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日There are two major categories of processing. One is comminution and the other one is separation. The process "Comminution" involves size reduction and size-wise classification called as...

IS 3612 (1994): Crushing and grinding equipment

A machine for breaking rock or similar material, mainly by compression between a crushing head which has more flared bell with bottom/inter- mediate support on spherical bearings and a bowl of tapering cross section within which the crushing head moves with an eccentric motion.

3 Important Indicators In Grinding And Classification Stage

2020年2月24日Grinding and Classifying Efficiency The efficiency in the grinding and classification stage mainly refers to the grinding efficiency, that is, the amount of ore processed by electric energy per kilowatt hour consumed, also known as the unit productivity of the mill.

The crushing and classification process of beneficiation

2021年1月18日Each time a material passes through a crusher or grinding machine, it is called a crushing or grinding section. For each stage of crushing or grinding operation, the ratio of the particle size before and after the crushing of the material (that is, the feed size to the product size) is defined as the crushing ratio or smashing ratio of the

crusher/sbm classification of crushing and grinding machinery

Contribute to yunan88/crusher development by creating an account on GitHub.

Crushing and Grinding Machine : Crushing and Grinding Machinery

SKL MINERAL PROCESSING EQUIPMENT Offering a wide range of Crushing and Grinding, Screening and Classification, Conveying, Ore Beneficiation, Ore Up-gradation/Metal Recovery from Scrap and Ore, Sampler, Special Purpose Equipment, Process Equipment, Blending/Mixing, Feeder, Pelletiser, etc. About Us

Classification of Recycled Aggregate: Crushing and Grinding YouTube

2019年8月22日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

11 Crushing and classification particles.uk

Classification is the term for industrially sorting particles into different size fractions or grades. 11 Crushing and classification Estimates vary, but it is generally accepted that of all the energy used in the World something like between 1 and 10% is in comminution, i.e. the processes of crushing, grinding, milling, micronising, etc.

CPE: Lesson 13. Principle of Size Reduction

For example, crushing, grinding, and milling take place in powdered sugar, , mustard, and cocoa production. Table 13.2 Types of forces used in size reduction equipments. Crushing: when an external force applied on a material excess of its strength, the material fails because of its rupture in many direction.

MINERAL ENGINEERINGFUEL TECHNOLOGY 4 Semester B.

crushing and grinding operation 2-sizing-Sizing is the separation of material or product into various fract ions characterised by difference in size. Sizing can be performed by screening or classification. The latter depends on the settling velocity of particles in a fluid (air or water). 3-concentration-Concentration may be regarded as

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

• Speed of crushing ranges between 125 to 425 gyrations per minute • Discharge from the gyratory crusher is continuous • Less maintenance is required as compared to jaw crusher • Power requirement is low . Crushing rolls • Mainly used for extraction of juice from sugarcane • Two types Smooth roll crusher

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

(PDF) Comminution in mineral processing

2018年11月19日Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies....

IS 3612 (1994): Crushing and grinding equipment

A machine for breaking rock or similar material, mainly by compression between a crushing head which has more flared bell with bottom/inter- mediate support on spherical bearings and a bowl of tapering cross section within which the crushing head moves with an eccentric motion.

3 Important Indicators In Grinding And Classification Stage

2020年2月24日Grinding and Classifying Efficiency The efficiency in the grinding and classification stage mainly refers to the grinding efficiency, that is, the amount of ore processed by electric energy per kilowatt hour consumed, also known as the unit productivity of the mill.

The crushing and classification process of beneficiation

2021年1月18日Each time a material passes through a crusher or grinding machine, it is called a crushing or grinding section. For each stage of crushing or grinding operation, the ratio of the particle size before and after the crushing of the material (that is, the feed size to the product size) is defined as the crushing ratio or smashing ratio of the

11 Crushing and classification particles.uk

Classification is the term for industrially sorting particles into different size fractions or grades. 11 Crushing and classification Estimates vary, but it is generally accepted that of all the energy used in the World something like between 1 and 10% is in comminution, i.e. the processes of crushing, grinding, milling, micronising, etc.

CPE: Lesson 13. Principle of Size Reduction

For example, crushing, grinding, and milling take place in powdered sugar, , mustard, and cocoa production. Table 13.2 Types of forces used in size reduction equipments. Crushing: when an external force applied

MINERAL ENGINEERINGFUEL TECHNOLOGY 4 Semester B.

crushing and grinding operation 2-sizing-Sizing is the separation of material or product into various fract ions characterised by difference in size. Sizing can be performed by screening or classification. The latter depends on the settling velocity of particles in a fluid (air or water). 3-concentration-Concentration may be regarded as

Classification of Grinding Machine PCD Tool

2019年4月29日Classification of Grinding Machine. Performance, variety and output of grinding machines are constantly improving with the increasing number of high-precision and high-hardness mechanical parts

Classification of Recycled Aggregate: Crushing and Grinding YouTube

2019年8月22日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

crusher/sbm classification of crushing and grinding machinery

Contribute to yunan88/crusher development by creating an account on GitHub.

Name already in use github

sbm classification of crushing and grinding machineriesnotes for classification of crushing and grinding. notes for classification of crushing and grinding machinery in chemical e

11.19.1 Sand And Gravel Processing US EPA

50 micrometers ( m) or smaller by grinding, using smooth rolls, media mills, autogenous mills, hammer mills, or jet mills. The ground material then is classified by wet screening, dry screening, or air classification. At some plants, after initial crushing and screening, a portion of the sand may be diverted to construction sand use.

AP-42, CH 11.7: Ceramic Products Manufacturing US EPA

Fine grinding or milling reduces the particle size down to as low as 1.0 micrometer (µm) (4 x 10-5in.) in diameter. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition mills, and fluid energy mills also are used. Crushing and grinding typically are dry processes; milling may be a wet or dry