Crusher For Coal Crushing

Coal McLanahan

根据热度为您推荐•反馈

Roll Crushers McLanahan

Roll Crushers. Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other

Crushing Astec

Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers,

进一步探索

Astec Kodiak® Cone Crushers AstecSouth Africa ASTEC根据热度为您推荐•反馈

Roll Crusher ManufacturerDesign Williams Crusher

Typical feed materials for Williams Roll Crushers include: bauxite, cement clinker, chalk, cinders, clay, coal, glass, gypsum, limestone, burnt lime, rock salt, sandstone, shale, sulfur ore, sea shells, and sewer sludge clinker.

Coal Crushers, 1.6mm / 4.75mm Final Particle Size

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotary-swing hammers. The enclosed cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low

Coal Crusher Types- Impact& Double Roller Crusher

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly

Coal Crushers Coal PulverizersMills Williams Crusher

The Williams Rigid Arm Breakers are well suited for softer friables, which allows it to be used as a coal crusher. The Rigid Arm Breaker features a unique design by using hammers that are rigid, rather than swing

Crushing McLanahan

Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant. The type of crusher required depends

Coal Crushers Coal PulverizersMills Williams

Through continuous innovation and dedication to quality, Williams Patent Crusher has become the industry leader in coal crushing and pulverizing equipment. We’ve maintained that commitment for over 150 years—and

Double Roll Crushers McLanahan

Heavy-Duty Double Roll Crushers are ideal for the primary, secondary and tertiary crushing of limestone, gypsum, ROM coal, etc. where higher compressive strength material is anticipated. Due to the V-belt drive

TerraSource Global Size ReductionCrusher Machines

Clinker Crushers reduce bottom ash or clinker produced by the types of boilers most commonly found in utility and industrial power plants. LEARN MORE Coalpactors by Pennsylvania Crusher Brand Coalpactors® effectively reduce the size of coals and are ideally suited for fluid bed boiler plants.

Sizers McLanahan

Direct Drive Crushing Sizers, specifically McLanahan Sizers, provide primary, secondary and tertiary reduction of friable, low silica materials such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, trona, carbon anodes, oil sands, clay, shale and more. Applications Coal Crushing Mining Jump To: How Sizers Work

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP.

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日Some roll crushers, notably the light coal crushing type, have more of a tearing action, as contrasted to the heavy sledging performance of such machines as the Fairmount crusher. Here are

Which Equipment Is Best For Crushing Wet Coal

2022年11月9日The wet coal crusher can crush all kinds of medium-hard and weakly abrasive materials. Mainly used in coal, electric power, scientific research and other industries and departments to crush and dry coal,

Coal Crusher, Coal Crushing Machine, Coal Crusher

Coal Crusher Since the compression strength of coal is about 5-50, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc. However, there exist special requirements for processing and using

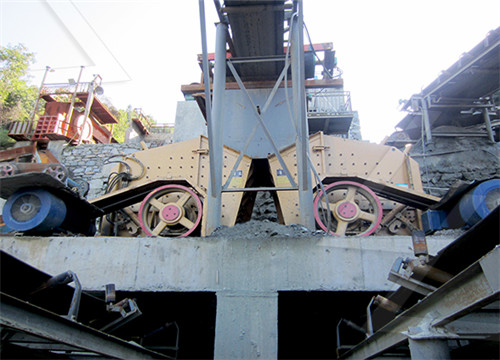

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine

220V Hammer Crusher Stone Glass Broken Coal Crushing

Coal Testing Machine 220V Small Hammer Crusher for Stone/Wet Coal/Glass Crushing. Sponsored. $1,051.86. $1,119.00. Free shipping. Open Box Hammer Glass Crusher Coal Glass Breaking Machine 3, 6, 10mm Screens. $711.55. $749.00 + $299.00 shipping. Hammer Crusher Stone Glass Broken Coal Testing Equipment 220V w/3&6&10mm

The difference between stone hammer crusher and impact crusher

2023年3月10日Hammer crushers use a single hammer to strike and break the material, while impact crushers use a combination of hammers and a crushing plate to strike and shatter the material. Crushing...

Crushers an overview ScienceDirect Topics

9.3.1 Coal Jaw Crusher. This is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal crushing industry. Jaw crushers are designed for primary crushing of hard rocks without rubbing and with minimum dust. Jaw crushers may be utilized for materials such as coal, granite, basalt, river

Coal Sizers, Coal sizers Crusher, Coal Mineral Sizers —Henan

Coal Sizer is a professional coal crushing equipment, mainly used for crushing raw coal, coal gangue, coal coke and other materials. According to the crushing degree, coal sizers can be divided into one-stage crusher and two-stage crusher. Our coal sizers has the characteristics of wear resistance, impact resistance, stable operation, convenient

Crushing McLanahan

Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant. The type of crusher required depends

Coal Crushers Coal PulverizersMills Williams

Through continuous innovation and dedication to quality, Williams Patent Crusher has become the industry leader in coal crushing and pulverizing equipment. We’ve maintained that commitment for over 150 years—and

Double Roll Crushers McLanahan

Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil

TerraSource Global Size ReductionCrusher Machines

Clinker Crushers reduce bottom ash or clinker produced by the types of boilers most commonly found in utility and industrial power plants. LEARN MORE Coalpactors by Pennsylvania Crusher Brand Coalpactors® effectively reduce the size of coals and are ideally suited for fluid bed boiler plants.

Sizers McLanahan

Direct Drive Crushing Sizers, specifically McLanahan Sizers, provide primary, secondary and tertiary reduction of friable, low silica materials such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, trona, carbon anodes, oil sands, clay, shale and more. Applications Coal Crushing Mining Jump To: How Sizers Work

Coal Crusher Crushco

CRUSHCO COAL CRUSHER 900HD. * The above tons per hour ranges are approximations and depends on several variables and includes material scalped before crushing. Variables to consider are; the type of coal and

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP.

Double Roller Crusher, Coal Crusher, Limestone Crusher Tianhe

Optimizing Crusher Operations for Production of Kiln Feed limestone. 1. Introduction A typical stone crushing operation for a lime operation includes a primary and a secondary crusher. A common primary crusher installation consists of a jaw crusher equipped with a grizzly feeder to bypass fines. Secondary crusher normally consists of cone...

Why is the crusher used in the coal mining area?

2023年3月8日Coal crusher from mpl A crusher is a machine that is used to reduce the size of large rocks or minerals into smaller pieces or dust. In the coal mining industry, crushers are used to...

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日Some roll crushers, notably the light coal crushing type, have more of a tearing action, as contrasted to the heavy sledging performance of such machines as the Fairmount crusher. Here are

220V Hammer Crusher Stone Glass Broken Coal Crushing

Coal Testing Machine 220V Small Hammer Crusher for Stone/Wet Coal/Glass Crushing. Sponsored. $1,051.86. $1,119.00. Free shipping. Open Box Hammer Glass Crusher Coal Glass Breaking Machine 3, 6, 10mm Screens. $711.55. $749.00 + $299.00 shipping. Hammer Crusher Stone Glass Broken Coal Testing Equipment 220V w/3&6&10mm

MMD Group of Companies Sizers

Sizer technology is the latest innovation in the crushing industry providing a compact and efficient way of comminution, both in underground and open pit operations. Currently MMD process over 80 different materials in more than 70 countries worldwide for primary, secondary or tertiary crushing operations. Introduction to the MMD Sizer FEATURES

Coal crusher, Coal crushing plant All industrial manufacturers

hammer crusher ZCJK. stationary coal fine. Contact. Capacity: 5 t/h 80 t/h. Motor power: 7.5 kW 132 kW. Hammer crusher is mainly used for crushing medium hardness and brittle materials, such as coal, cement, plaster, alum, brick, tile, limestone. Compressive strength of material should not exceed 300 MPa,