Simple Structure And Little Noise Coal Magnetic Separator

Design and Research of a Three-Phase AC Magnetic

The simulation results show that the structure design of the three-phase AC magnetic separator is reasonable. Keywords: magnetic separation desulfurization; three-phase AC magnetic separator

(PDF) Design and Research of a Three-Phase AC Magnetic

2020年4月21日PDF China’s total coal consumption accounts for 50% of total energy consumption. However, every ton of coal in the process of production and use will

Magnetic Separator an overview ScienceDirect Topics

Small particles tend to agglomerate and pass through the separator. It has been shown that individual particles of coal in the discharge of a power plant pulveriser flow freely and

进一步探索

How does a magnetic separator work and what uses can iHow Does a Magnetic Separator Work? An Intro to Magneti根据热度为您推荐•反馈

Magnetic separation Wikipedia

OverviewHistoryCommon applicationsMagnetic cell separationIn microbiologyLow-field magnetic separationWeak magnetic separationEquipment and Services

Magnetic separation is the process of separating components of mixtures by using a magnet to attract magnetic substances. The process that is used for magnetic separation separates non-magnetic substances from those which are magnetic. This technique is useful for the select few minerals which are ferromagnetic (iron-, nickel-, and cobalt-containing minerals) and paramagnetic. Most metals, including gold, silver and aluminum, are nonmagnetic.

Dense Media Separation (DMS) Plants JXSC Machine

2022年2月17日It can be separated by simple ways like magnetic separation, flotation, or classification. 3. Wide range of sources, low prices, and no harmful impurities. DMS

In Line Magnetic Separator ILMS Coal Handling Plants

2018年9月4日In Line Magnetic Separator (ILMS) are used for continuous and automatic extraction or discharge of unwanted magnetic pieces (tramp iron) from the point where

How does a magnetic separator work and what uses can

A magnetic separator is a device that uses a magnet to remove impurities and other magnetic materials from metal. Magnetic separators can be used before, during and

Industrial Permanent Magnetic Separator for Handling Coal

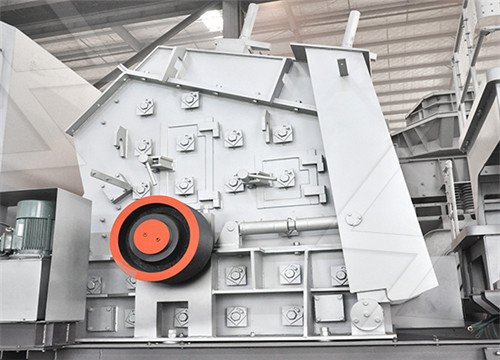

1.Technical features of coal magnetic separator. The fully sealed magnetic system is composed of ferrite and rare earth magnetic steel. The corresponding structure to

Magnetite recovery in coal washing by high gradient magnetic

A single-stage separator incorporating a new matrix design was used at rates up to 4.4 tons of solids per hour per square foot of matrix cross section (300 gpm/sq ft). At this

China Customized Coal Magnetic Separator Manufacturers

Coal Magnetic Separator The fully sealed magnetic system is composed of ferrite and rare earth magnetic steel. The corresponding structure to produce reasonable pulp flow

Design and Research of a Three-Phase AC Magnetic Separator for Coal

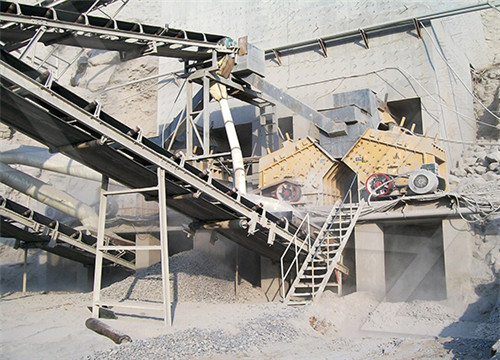

2020年3月25日China’s total coal consumption accounts for 50% of total energy consumption. However, every ton of coal in the process of production and use will bring huge losses to the environment. Desulfurization and ash removal of coal have been a continuous focus of researchers in various countries. The three-phase alternating current

(PDF) Design and Research of a Three-Phase AC Magnetic Separator

2020年4月21日PDF China’s total coal consumption accounts for 50% of total energy consumption. However, every ton of coal in the process of production and use will Find, read and cite all the research

Design and Research of a Three-Phase AC Magnetic

The simulation results show that the structure design of the three-phase AC magnetic separator is reasonable. Keywords: magnetic separation desulfurization; three-phase AC magnetic separator

How does a magnetic separator work and what uses

A magnetic separator is a device that uses a magnet to remove impurities and other magnetic materials from metal. Magnetic separators can be used before, during and after the production of a material and can be

Magnetite Recovery in Coal Washing by High Gradient Magnetic Separation

High values of magnetite recovery were achieved at reasonably high material throughput rates with little coal found reporting to the magnetics. A single-stage separator incorporating a new matrix design was used at rates up to 4.4 tons of solids per hour per square foot of matrix cross-section (300 gpm/ft2). the Reiss-Viking magnetite was

China Customized Coal Magnetic Separator Manufacturers

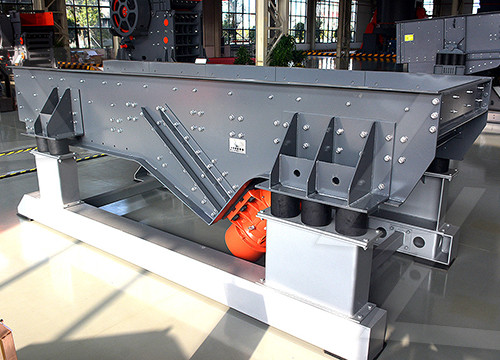

The modular structure is adopted in the double drum magnetic separator to facilitate magnetic separation, transportation and installation. Strong adaptability to the change of material flow, concentration and other parameters. Separation granularity range: 0-3mm. Simple structure, large capacity, easy operation and maintenance. Adopted standard

Intensity Magnetic Separator an overview ScienceDirect Topics

The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices.

Magnetic separation Wikipedia

The process that is used for magnetic separation separates non-magnetic substances from those which are magnetic. This technique is useful for the select few minerals which are ferromagnetic(iron-, nickel-, and cobalt-containing minerals) and paramagnetic.[2] Most metals, including gold, silver and aluminum, are nonmagnetic.

How Does A Magnetic Separator Work? gtek

1. Magnetic Separators for concentration or purification; Magnetic Separator can be applied in ore processing for separating magnetic materials, particular Iron. The advent of magnetic separation found

Magnetic Separator Equipment Knowledge You Don't Know

2019年8月30日The magnetic system of magnetic separator is made of high-performance rare earth boron material and high-quality ferrite material. The maximum magnetic induction intensity of the barrel sorting area is above 0.8T, and the magnetic field strength is 3-5 times that of the conventional coal magnetic separator.

Fine Particle Magnetic Separators Eclipse Magnetics

Our magnetic separators are widely used in , pharmaceutical, chemical and other processing industries. Our magnetic separators are ideal to identify and remove metal contamination from bulk materials such as grain, powders, granules, and liquids. They minimize the risk of costly product recalls, process stoppages, and damage to expensive

Magnetic Separators Coal Conveyor Magnetic Separators

Manufacturer of Magnetic Separators Coal Conveyor Magnetic Separators, Magnetic Drum Separator, Magnetic Wet Drum Separator and Magnetic Coolant Separator offered by Magna Tronix, Chennai, Tamil Nadu.

ISO9001 Vertical Pipeline Permanent/Mineral Magnetic Separator

The modular structure is adopted in the double drum magnetic separator to facilitate magnetic separation, transportation and installation. Strong adaptability to the change of material flow, concentration and other parameters. Separation granularity range: 0-3mm. Simple structure, large capacity, easy operation and maintenance. Adopted standard

Design and Research of a Three-Phase AC Magnetic Separator for Coal

2020年3月25日China’s total coal consumption accounts for 50% of total energy consumption. However, every ton of coal in the process of production and use will bring huge losses to the environment. Desulfurization and ash removal of coal have been a continuous focus of researchers in various countries. The three-phase alternating current

Design and Research of a Three-Phase AC Magnetic

The simulation results show that the structure design of the three-phase AC magnetic separator is reasonable. Keywords: magnetic separation desulfurization; three-phase AC magnetic separator

(PDF) Design and Research of a Three-Phase AC Magnetic Separator

2020年4月21日PDF China’s total coal consumption accounts for 50% of total energy consumption. However, every ton of coal in the process of production and use will Find, read and cite all the research

SUSPENDED PERMANENT MAGNETIC SEPARATOR Eriez

maintaining the Eriez Suspended Permanent Magnetic Separator. Careful attention to these requirements will assure the most efficient and dependable performance of this equipment. If there are any questions or comments about the manual, please call Eriez at 814-835-6000 for Magnetic Separator assistance. CAUTION

Magnetite Recovery in Coal Washing by High Gradient Magnetic Separation

High values of magnetite recovery were achieved at reasonably high material throughput rates with little coal found reporting to the magnetics. A single-stage separator incorporating a new matrix design was used at rates up to 4.4 tons of solids per hour per square foot of matrix cross-section (300 gpm/ft2). the Reiss-Viking magnetite was

China Customized Coal Magnetic Separator Manufacturers

Coal Magnetic Separator The fully sealed magnetic system is composed of ferrite and rare earth magnetic steel. The corresponding structure to produce reasonable pulp flow direction in the separation equipment is ingeniously designed. Send InquiryChat Now Product Details Coal magnetic separator 1.Technical features of coal magnetic

Intensity Magnetic Separator an overview ScienceDirect Topics

The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices.

Magnetic separation Wikipedia

The process that is used for magnetic separation separates non-magnetic substances from those which are magnetic. This technique is useful for the select few minerals which are ferromagnetic(iron-, nickel-, and cobalt-containing minerals) and paramagnetic.[2] Most metals, including gold, silver and aluminum, are nonmagnetic.

Industrial Permanent Magnetic Separator for Handling Coal

1.Technical features of coal magnetic separator. The fully sealed magnetic system is composed of ferrite and rare earth magnetic steel. The corresponding structure to produce reasonable pulp flow direction in the separation equipment is ingeniously designed. The modular structure is adopted in the double drum magnetic separator to facilitate

Overhead Magnetic SeparatorsConveyor Magnets

Magnetic Head Pulleys. Our head pulleys and drum magnets provide continuous protection against tramp iron contamination of both large and fine metal particles. We offer magnet sizes for every application, as small as 4″ diameter. Our magnetic pulleys are available in regular strength and a “high power” version for more extreme applications.

Magnetic field Eriez

The purpose of the wet drum magnetic separator in a coal preparation operation is to recover magnetite in the heavy media circuit. When properly applied, the mag-netic loss to the wet drum non-magnetic ef-fluent will be reduced to less than 0.25 g

Fine Particle Magnetic Separators Eclipse Magnetics

Our magnetic separators are widely used in , pharmaceutical, chemical and other processing industries. Our magnetic separators are ideal to identify and remove metal contamination from bulk materials such as grain, powders, granules, and liquids. They minimize the risk of costly product recalls, process stoppages, and damage to expensive