Tin Ore Processing In Iran

Tin processing Britannica

tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft and ductile metal with a silvery white colour. It has a density of 7.29 grams per cubic

Tin processing Mining and concentrating Britannica

The principle of tin smelting is the chemical reduction of tin oxide by heating with carbon to produce tin metal and carbon dioxide gas. In practice, the furnace feed contains the tin

进一步探索

10 Top Tin-producing Companies MineListingsTin Ore Extraction Mineral ProcessingMetallurgy根据热度为您推荐•反馈

Tin sources and trade in ancient times Wikipedia

OverviewTradeEarly useArchaeological importanceAncient sourcesSee alsoCited works

Due to the scattered nature of tin deposits around the world and its essential nature for the creation of tin bronze, tin trade played an important role in the development of cultures throughout ancient times. Archaeologists have reconstructed parts of the extensive trade networks of ancient cultures from the Bronze Age to modern times using historical texts, archaeological excavations

Tin Ore Extraction Mineral ProcessingMetallurgy

2016年5月24日Tin Ore Extraction The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration

Cassiterite the Tin Ore Mineral Overview

2018年11月26日The earliest documented accounts of tin mining there date to 1305-1306, when county records reflect active shipping of tin to the county seat of Truro. Among its historic engineering firsts are the site of

Tin Ore Processing

2017年2月16日Tin Ore Processing The methods employed in dressing the tin ore up to the required percentage of purity depend mainly on the type of ore crushed. These may be briefly divided into two distinct

Tin Mining, Processing Solutions and Equipment

Tin Mining, Processing Solutions and Equipment. +. [email protected] Inquire Now. There are more than 50 kinds of tin-containing minerals known in nature,

Evidence for Early Bronze Age tin ore processing

DOI: 10.1016/S1044-5803(00)00111-X Corpus ID: ; Evidence for Early Bronze Age tin ore processing @article{Laughlin2000EvidenceFE, title={Evidence for Early

Tin Processing Equipment, Process Flow, Cases JXSC

2019年9月25日Tin ore is usually extracted by gravity separation, which is determined by the fact that tin ore has a higher density than symbiotic minerals. However, tin ore is often accompanied by iron oxide minerals

Mining in Iran Wikipedia

Iran Central Iron Ore Company produced 5,310,000 mt, with the remainder produced by other smaller public sector miners. [45] In 2009, Iran exported about 10 million metric tons of iron ore, mainly to China. [41] Gohar Zamin Iron Ore Mine is expected to produce 140 million tons of ore by 2013. [46]

(PDF) Pilot Plant for the Processing of a Complex Tin

2020年3月31日A dry magnetic separation by a drum type magnetic separator served as a case study to visualize effects of processing of a skarn ore with a high content of cassiterite as ore mineral (~4 wt

Tin sources and trade in ancient times Wikipedia

Tin is an essential metal in the creation of tin-bronzes, and its acquisition was an important part of ancient cultures from the Bronze Age onward. Its use began in the Middle East and the Balkans around 3000 BC. Tin is a

DQGPDJQHWLFVHSDUDWLRQ Institute of Physics

Tin (Sn) content in primary tin ore ranges from 0.2 1.0%. The Sn particles liberated in the cassiterite mineral are above 50% so they can be processed by the physical separation method. This research aims to observe the beneficiation of cassiterite from primary tin ore (oxide and skarn samples) using gravity and magnetic separation.

Cassiterite the Tin Ore Mineral Overview

2018年11月26日Cassiterite is the major ore of tin. Its fundamental characteristics are: non-magnetic, non-combustible, corrosion-resistant, lightweight, durable, soft, ductile, malleable, expensive and low

Extraction of Tin From Its Ore JXSC Machine

2018年10月25日Then go to the gold separation machine and concentration machine ( tin ore shaking table). 3.Pre-selection stage. After crushing and sieving, the ore of 4-20mm should be pre-processed by

Tin Mining, Processing Solutions and Equipment

There are more than 50 kinds of tin-containing minerals known in nature, and within them, about 20 kinds are tin abundance minerals. The most important and economic significance tin containing ore is cassiterite, followed by yellow tin ore.

Iran discovers 8.5 million ton lithium deposit Mining Technology

2023年3月7日The Iranian government claims it has discovered a massive deposit of lithium, potentially holding 8.5 million tons of the rare element. Mohammad Hadi Ahmadi, an official at Iran’s Ministry of Industry, Mines and Trade, announced the discovery on Iranian state television.

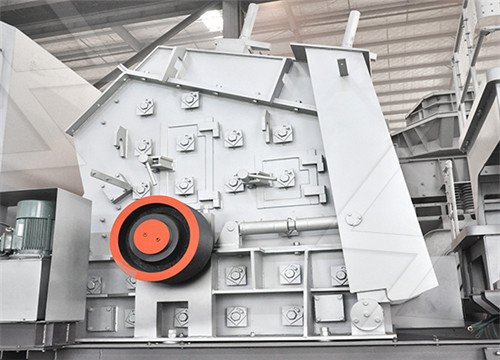

Mobile Crusher and Grinding Mill Used in Iran Mineral Processing

Iran has rich mineral materials, such as copper ore, coal. Copper ore mobile crusher plant and coal grinding mill will be used to process these materials. Crushing equipment for tin ore processing in Indonesia; Saudi Arabia Mining Crusher Plant For Sale,crushing equipment supplier; Saudi Arabia Mining Industry: Gold Ore and Copper Ore Mining;

Rock coltan tin ore processing plant setup YouTube

2022年1月13日This Setup is a rock coltan tin ore processing plant.It is configured with a vibration feeder, jaw crusher, cone crusher, vibration screen, belt conveyor, ha This Setup is a rock

Tin Geoscience Australia

Processing The first step in processing the tin is ensuring that a suitable ore concentrate is formed. Tin ores that contain high sulphide mineral contents have to undergo an additional process, whereby the ore is

From Ore to Finished Product Copper

Copper ore is extracted using two basic methods of mining open pit or underground mining. 3. Processing of Copper Ore The first step in processing the ore removed from the mine is to break the large rocks of ore into smaller pieces. This is accomplished by a variety of subsequent processing steps. 4. Beneficiation of Copper Ore

Graphic Not Available. US EPA

than 80% of the tin ore in the world is found in placer deposits with tin content as low as 0.015%.1 Final uses of tin include cans and con tainers, electrical components, Processing," presented at the Conference for Emerging Separation Technologies for Metals and Fuels, Palm Coast, FL, March 13-18, 1993, sponsored by the Minerals, Metals

Crushing equipment for tin ore processing in Indonesia

Tin ore Processing Operation The process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore.Tin deposits in Indonesia are located in the gravel along streambeds and require the use of dredges or pumps to reach the ore.

Tin Mining and Processing: Everything you Need to

Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees Fahrenheit. The next step involves leaching with acid or water solutions to remove impurities. Electrostatic or

ProcessingSmelting PT TIMAH TBK

The results of this process are bar or rod-shaped refined tin that has a weight scale ranging from 23kg to 27 kg per bar. The refined tin produced by PT TIMAH Tbk has a trademark registered on London Metal Exchange (LME>. 100% of tin products are ISO 90001 : 2008 certified, reinforcing PT TIMAH Tbk Commitment to the application of best

Tin sources and trade in ancient times Wikipedia

Tin is an essential metal in the creation of tin-bronzes, and its acquisition was an important part of ancient cultures from the Bronze Age onward. Its use began in the Middle East and the Balkans around 3000 BC. Tin is a

Cassiterite an overview ScienceDirect Topics

The tin slag in the first stage typically contains 30–40% SiO 2, 15–25% FeO, 5–15% CaO, and 5–25% SnO 2. In the second stage, the tin silicate is reduced by iron metal to form iron silicate and an impure tin, which is recycled.

Cassiterite the Tin Ore Mineral Overview

2018年11月26日Cassiterite is the major ore of tin. Its fundamental characteristics are: non-magnetic, non-combustible, corrosion-resistant, lightweight, durable, soft, ductile, malleable, expensive and low

DQGPDJQHWLFVHSDUDWLRQ Institute of Physics

Tin (Sn) content in primary tin ore ranges from 0.2 1.0%. The Sn particles liberated in the cassiterite mineral are above 50% so they can be processed by the physical separation method. This research aims to observe the beneficiation of cassiterite from primary tin ore (oxide and skarn samples) using gravity and magnetic separation.

Extraction of Tin From Its Ore JXSC Machine

2018年10月25日Then go to the gold separation machine and concentration machine ( tin ore shaking table). 3.Pre-selection stage. After crushing and sieving, the ore of 4-20mm should be pre-processed by

Mobile Crusher and Grinding Mill Used in Iran Mineral Processing

Iran has rich mineral materials, such as copper ore, coal. Copper ore mobile crusher plant and coal grinding mill will be used to process these materials. Crushing equipment for tin ore processing in Indonesia; Saudi Arabia Mining Crusher Plant For Sale,crushing equipment supplier; Saudi Arabia Mining Industry: Gold Ore and Copper Ore Mining;

Mining Sector Profile Uganda Investment Authority

Uses: The commonest use of gold is in gold bullion, followed by jewelry and electronics especially in the computer industry. Iron Ore: Iron ore occurs principally as two types of minerals: hematite and magnetite. Hematite of high quality (90-98% Fe2O3) occurs at Butare in Kabale district; Kashenyi, Kyanyamuzinda and Kamena in Kisoro district with

Crushing equipment for tin ore processing in Indonesia

Tin ore Processing Operation The process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore.Tin deposits in Indonesia are located in the gravel along streambeds and require the use of dredges or pumps to reach the ore.

Renison Tin Mine, Tasmania, Australia Mining

2021年4月9日The project is aimed at recovering tin from around 22.5Mt of tailing deposits at an average grade of 0.44% tin and 0.23% copper from the historic ore processing at the Renison mine. Location and history of

Tin Processing at Göltepe, an Early Bronze Age Site in

Tin Processing at Goltepe, an Early Bronze Age Site in Anatolia K. ASLIHAN YENER AND PAMELA B. VANDIVER An Early Bronze Age Source of Tin Ore in the Taurus Mountains, Tur-key," Science 244 (1989) 200-203. ASSUR IRAN CYPRUS SYRIA IRAQ'. N 00 200 300 Kilometers 0 100 200 300 4 0 Kilometers

Erzgebirge/Krušnohoří Mining Region UNESCO World Heritage

2019年7月6日The cultural landscape of the Ore Mountains has been deeply shaped by 800 years of almost continuous mining, from the 12th to the 20th century, with mining, pioneering water management systems, innovative mineral processing and smelting sites, and mining cities. Description is available under license CC-BY-SA IGO 3.0 English

TSHA Tin Smelting Handbook of Texas

By 1953 the Texas City smelter was able to handle all grades of tin from pure alluvial to low-grade primary ore. The annual capacity of the two-step, natural gas-fired reverberatory furnace was 96,000 tons, with 99.75 percent purity or better. In 1955 the $13,000,000 facility was put up for sale by the Office of Defense Mobilization to block a