Mining Machinery For Silver Ore Process And Machinery

Silver Mining Processing Equipment Flow Chart Cases JXSC

The process of mining for silver is broken down into three steps: removing ore from the earth, breaking it down and then flushing the silver from ore. The first step involves

Silver mining equipment, silver crushing and grinding machines,

Silver ore crusher such as Jaw Crusher, Cone Crusher, Impact Crusher and ore grinder such as Ball Mill, Raymond Mill, High Pressure Mill, are commonly used in the silver

Mining Tools in 2022—A Guide to Mining Equipment and

Types of Mining MethodsMining Tools and EquipmentMiner ToolsMining PPESurface Mining EquipmentUnderground Mining EquipmentOther Mining Tools

Here are all the types of mining tools used in underground mining: 1. Crane lifts 2. Continuous miners 3. Drones 4. Jumbo drills 5. Loaders and haulers 6. Longwall mining machines 7. Personnel vehicles 8. Refuge chambers 9. Rock dusters 10. Roof bolters 11. Scoops 12. Shotcrete machines 13. Shuttle cars 14. Underground rails 15. Ventilation systems

Common Types of Mining Equipment Used in the Mining

Large Mining Trucks. To move materials around a mine site, workers need heavy-duty

Silver Mining and Refining Education

Discover the mining and refining process of the precious metal of silver. See a discussion on the history of this process including facts, figures, interesting and historical pictures, and the people and places involved.

Silver Ore Flotation Process, Equipment Mineral

In order to extract the silver, the silver ore needs to be crushed and ground, and the beneficiation method is used to pre-enrich or separate the silver from the ore. The jaw crusher is used for coarse crushing and

MiningMineral Processing Equipment FEECO International Inc.

Mining and Mineral Processing Equipment FEECO Mining Capabilities Our equipment and solutions are used around the world in a variety of mining and mineral processing operations. We’ve worked with everyone from process start-ups and entrepreneurs, to Fortune 100 companies. Equipment

How is Silver Mined? APMEX

2022年5月24日While many technologies exist, Silver is typically mined through a process that uses gravity to break and extract ore from large deposits. The exact method of ore removal used varies by the physical characteristics of the rock surrounding the metal, as well as the unique shape of the deposit.

Mining and Rock Excavation Equipment, Mining Machines

Mining and Rock excavation Products and Mining Equipment Whether you need to excavate, transport or process ore, rock or overburden more efficiently, our comprehensive range of cutting-edge surface and underground mining equipment is designed to increase your productivity and boost your bottom line. Parts and services offering >

Visualized: The silver mining journey from ore to more

2021年7月29日In 2020, 784.4 million ounces of silver were mined across the world according to Metals Focus. While production is forecasted to increase by ~8% to reach 848.5 million ounces in 2021, it’s still

Silver Mining Processing Equipment Flow Chart Cases JXSC

The process of mining for silver is broken down into three steps: removing ore from the earth, breaking it down and then flushing the silver from ore. The first step involves drilling holes in the silver-rich areas geologists have previously pinpointed and then inserting dynamite sticks.

Silver mining equipment, silver crushing and grinding machines, silver

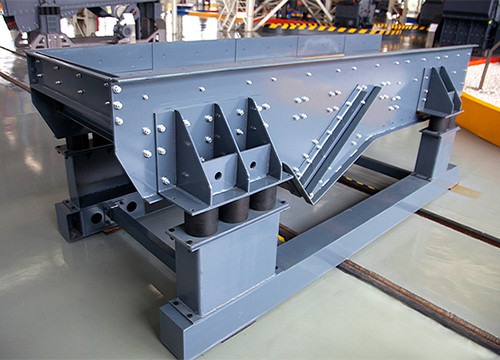

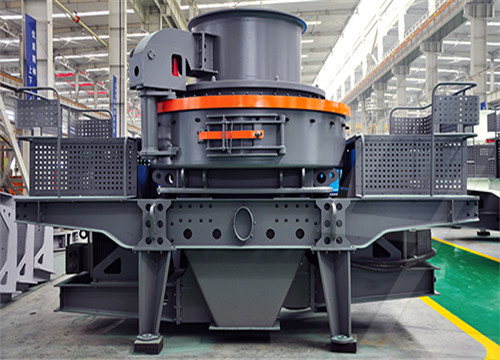

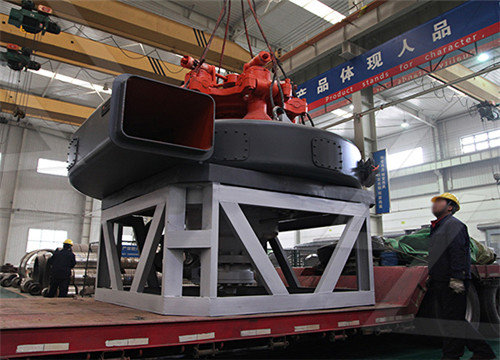

Silver ore crusher such as Jaw Crusher, Cone Crusher, Impact Crusher and ore grinder such as Ball Mill, Raymond Mill, High Pressure Mill, are commonly used in the silver mining process. Our crushers have a very important role in silver ores mining, especially in silver ores’ crushing process. Jaw Crusher Impact Crusher Hammer Crusher Ball Mill

Silver Ore Flotation Process, Equipment Mineral

In order to extract the silver, the silver ore needs to be crushed and ground, and the beneficiation method is used to pre-enrich or separate the silver from the ore. The jaw crusher is used for coarse crushing and

Mining Equipment for Sale JXSC Mining

JXSC Mine Machinery Factory (aka.JXSC Mining) provides a variety of mining equipment and mineral processing equipment for sale.Our equipment not only applied in large mining plants but also suitable for small scale metallurgy operations operated by small miners. whether you are making big business in the mineral industry or a small one, even you are

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

What Are Differences in Beneficiation Process between Aphanitic and Fine Flake Graphite Ore? 2023-03-06; High Purity Quartz Sand Magnetic-Flotation-Acid Immersion Separation Process 2023-03-03; Equipment and Quotation for Quartz Sand Production Line 2023-03-01; Xinhai Mining at MINEXPO TANZANIA 2023 2023-02-27

Mining Wet Pan Mill Machine For Ore Dressing Production Line

Applicable industries: Building Material Shops, Construction works,EnergyMining, Video outgoing-inspection: Provided, Machinery test USD ($) USD United States Dollar (US$) EUR Euro (€) GBP British Pound (£) Mining Wet Pan Mill Machine For Ore Dressing Production Line in Zhengzhou, China.

Gold Mining Equipment for 2023 911Metallurgist

Our equipment is best used in small-scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE’ offers gold mining equipment as well as processing

8 Pieces of Gold Mining Equipment That Help You Recover More

2023年2月15日Shaking table, also called shaker table, is the best gravity separation device for gold, silver, tin, etc. It can process both gold-containing quartz powder and placer gold. The feeding particle size range of the

Visualized: The Silver Mining Journey From Ore to More

2021年7月28日In 2020, 784.4 million ounces of silver were mined across the world according to Metals Focus. While production is forecasted to increase by ~8% to reach 848.5 million ounces in 2021, it’s still greatly outpaced by growing demand for silver. Silver demand is forecasted to see a 15% YoY increase from 2020’s 896.1 million ounces to

Open-Pit Mining Method and Process Epiroc US

2021年1月7日Open-Pit Mining Method and Process Open-pit mining Open-pit mining provides significant proportions of many of the world's major mineral commodities. In hard rock mining, much of the world's annual output of copper, gold and iron ore is won from open-pit operations.

MiningMineral Processing Equipment FEECO International Inc.

Mining and Mineral Processing Equipment FEECO Mining Capabilities Our equipment and solutions are used around the world in a variety of mining and mineral processing operations. We’ve worked with everyone from process start-ups and entrepreneurs, to Fortune 100 companies. Equipment

How is Silver Mined? APMEX

2022年5月24日While many technologies exist, Silver is typically mined through a process that uses gravity to break and extract ore from large deposits. The exact method of ore removal used varies by the physical characteristics of the rock surrounding the metal, as well as the unique shape of the deposit.

Mining and Rock Excavation Equipment, Mining Machines

Mining and Rock excavation Products and Mining Equipment Whether you need to excavate, transport or process ore, rock or overburden more efficiently, our comprehensive range of cutting-edge surface and underground mining equipment is designed to increase your productivity and boost your bottom line. Parts and services offering >

Visualized: The Silver Mining Journey From Ore to More

2021年7月28日Crushing and Separating Mined Silver Ore Once the ore has been mined and transported out of the mine, it goes through a variety of crushers which break down the ore into small chunks. The chunks of silver ore are crushed and ground into a fine powder, allowing for the separation process to begin.

Visualized: The silver mining journey from ore to more

2021年7月29日Crushing and Separating Mined Silver Ore Once the ore has been mined and transported out of the mine, it goes through a variety of crushers which break down the ore into small chunks. The...

Silver mining equipment, silver crushing and grinding machines, silver

Silver ore crusher such as Jaw Crusher, Cone Crusher, Impact Crusher and ore grinder such as Ball Mill, Raymond Mill, High Pressure Mill, are commonly used in the silver mining process. Our crushers have a very important role in silver ores mining, especially in silver ores’ crushing process. Jaw Crusher Impact Crusher Hammer Crusher Ball Mill

Silver Ore Flotation Process, Equipment Mineral

In order to extract the silver, the silver ore needs to be crushed and ground, and the beneficiation method is used to pre-enrich or separate the silver from the ore. The jaw crusher is used for coarse crushing and

Mining Equipment for Sale JXSC Mining

Mineral processing equipment includes: ball mill, crusher, pulverizer, jaw crusher, impact crusher, cone crusher, ultra-fine crusher, magnetic separator, dry magnetic separator, wet magnetic separator, double force ring height Gradient magnetic separator, magnetite ore dressing equipment, flotation machine, mining flotation machine, classifier,

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation

What Are Differences in Beneficiation Process between Aphanitic and Fine Flake Graphite Ore? 2023-03-06; High Purity Quartz Sand Magnetic-Flotation-Acid Immersion Separation Process 2023-03-03; Equipment and Quotation for Quartz Sand Production Line 2023-03-01; Xinhai Mining at MINEXPO TANZANIA 2023 2023-02-27

Mining Wet Pan Mill Machine For Ore Dressing Production Line

Applicable industries: Building Material Shops, Construction works,EnergyMining, Video outgoing-inspection: Provided, Machinery test USD ($) USD United States Dollar (US$) EUR Euro (€) GBP British Pound (£) Mining Wet Pan Mill Machine For Ore Dressing Production Line in Zhengzhou, China.

DMS Mining Process, Equipment Mineral Processing

Dense media separation (DMS) or heavy media separation is a pre-concentration technique used to reject gangue minerals prior to grinding. DMS exploits the difference in specific gravity between the target and gangue minerals, and is commonly used in the separation of spodumene from other gangue silicates. The specific gravity of spodu-mene is

First Quantum, government reach deal on Cobre Panama

2 First Quantum Minerals’ (TSX: FM) shares rose Wednesday after the company said its local unit Minera Panama inked a draft concession contract with the Panamanian government for the Cobre Panama mine. The proposed agreement, which follows months of difficult negotiations, meets the goals the government outlined in January 2022 regarding

Silver Ore Types and Mineral Deposit JXSC Mining

2019年5月9日Silver Ore Type and Mineral Deposit in the World. Abstract. The world mineral resources of silver ores are mainly located in Russia, Mexico, Canada, USA, Australia and Peru. major silver deposits can be grouped as following types: (1) epithermal vein silver, related to the Mesozoic and Cenozoic volcanic ore and subvolcanic rocks,