Design Of Vertical Grinding Mill For Iron Ore Fines

(PDF) DEVELOPMENT OF A LABORATORY TEST TO

2018年9月17日Methods fordesigning vertical stirred mills involve operational experience, pilot plants and bench tests. An important issue is thatthese testsrequire, at a laboratory

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle.

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日A typical type of fine grinder is the ball m ill. These vertical grinding mills are wide ly used in . calcite, talcum, barite,

sbm design of vertical grinding mill for iron ore fines.md

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

Eco-efficient and cost-effective process design for

2015年2月24日Eco-efficient and cost-effective process design for magnetite iron ore . (HPGR) for fine crushing (Dunne, 2006) and stirred milling for fine grinding (Gao et al.,

Fine Dry Grinding of Iron Ore for Pelletizing

2019年6月20日The mill discharge, which is the final product, is discharged through an airslide system either to a cement-type vertical ore cooler and then to the product conveyor or directly onto the product

HIGmill high intensity grinding mill Metso Outotec

High intensity grinding mill. The Metso Outotec HIGmill™ is an advanced, energy-efficient fine and ultra-fine grinding solution that utilizes proven technology. With the tall, narrow, vertical body arrangement, grinding

Iron ore grinding millGrinding plants for Iron Ore

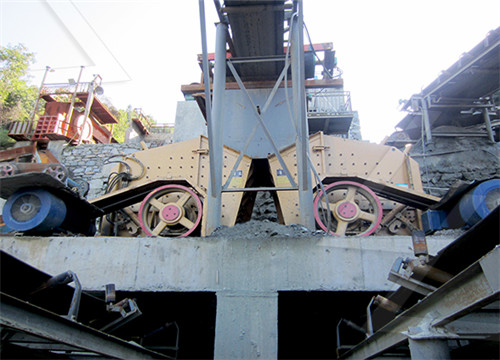

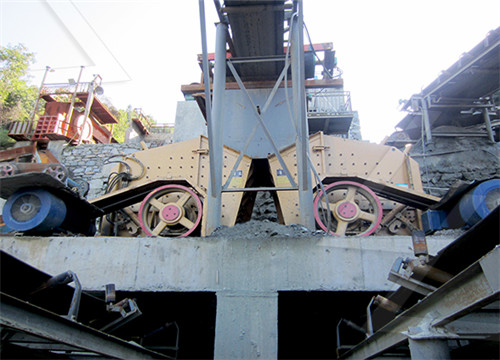

Iron ore blocks will be crushed to 15mm-50mm fineness by crusher. Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日In summary, four separate processes take place in this compact machine: grinding, classifying, transport and drying. Download : Download full-size image Fig. 1. Schematic operation principle of a vertical-roller-mill. A VRM offers several possibilities to control the grinding process.

(PDF) DEVELOPMENT OF A LABORATORY TEST TO DESIGN VERTICAL STIRRED MILLS

2018年9月17日Methods fordesigning vertical stirred mills involve operational experience, pilot plants and bench tests. An important issue is thatthese testsrequire, at a laboratory scale, atleast 1020 kg of...

Vertical mill simulation applied to iron ores ScienceDirect

2015年4月1日The vertical mill is basically composed of a cylinder with an internal screw that promotes the movement of the grinding media and slurry. This movement is provided by a motor installed on the top of the cylinder and connected to the screw via a gear unit. A separator tank directs part of the material exiting the mill via a recirculation pump.

Application of vertical stirred mill in iron ore fine grinding

2014年1月1日Download Citation Application of vertical stirred mill in iron ore fine grinding Vertical stirred mill is expected to upgrade the iron concentrate by further size reduced efficiently

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日DOI: 10.1016/J.MINENG.2014.07.021 Corpus ID: ; Research of iron ore grinding in a vertical-roller-mill @article{Reichert2015ResearchOI, title={Research of iron ore grinding in a vertical-roller-mill}, author={Mathis Reichert and Carsten Gerold and Andreas Fredriksson and G. Adolfsson and Holger Lieberwirth},

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

sbm design of vertical grinding mill for iron ore fines.md main

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

Sintering: A Step Between Mining Iron Ore and

2019年6月11日Sinter is the primary feed material for making iron and steel in a blast furnace. According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw materials,

Eco-efficient and cost-effective process design for magnetite iron ore

2015年2月24日Option 4 is an attempt to design a circuit with the lowest operating cost through increased grinding energy efficiency using three stages of magnetic separation, traditional autogenous milling, HPGR and stirred milling technology. In this conceptual flowsheet, steel grinding media is eliminated.

Metso Outotec to deliver energy-efficient Vertimill® grinding mills

2022年8月2日Metso Outotec to deliver energy-efficient Vertimill® grinding mills for an iron ore project in South America. From the design and supply of equipment for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help. manufacturing and supply of four Vertimill ® vertical grinding mills.

Vertimill VS Ball Mill GrindingClassification Circuits

There are two different types of vertical mills: Vertical roller mills. Such mills normally have integrated classifier. This means plant design is more compact / simple in comparison to ball mill / classifier circuit. On the other hand fineness is limited. Agitated vertical mills.

Iron Ore Processing, General SpringerLink

2022年10月20日Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills. Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions.

Buy Ore Ball Mill for Mineral Processing IronGold Ore Ball Mill

Ore Ball Mill. Output size: 0.074-0.89mm. Motor power: 18.5-480kw. Specification (mm): Φ750×750-Φ2700×4500. Applications: It is used for processing various grindable mineral materials, non-ferrous metal mineral processing, new building materials, etc. Email: info@ballmillssupplier. Now.

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet Plant In

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly driven by the growing need for steel in end-use industries such as the automobile industry, shipbuilding industry, construction

Application of vertical stirred mill in iron ore fine grinding

2014年1月1日Vertical stirred mill is expected to upgrade the iron concentrate by further size reduced efficiently. The tests for fine grinding of iron ores from Baiyun Boyu iron ore, Baogang...

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日DOI: 10.1016/J.MINENG.2014.07.021 Corpus ID: ; Research of iron ore grinding in a vertical-roller-mill @article{Reichert2015ResearchOI, title={Research of iron ore grinding in a vertical-roller-mill}, author={Mathis Reichert and Carsten Gerold and Andreas Fredriksson and G. Adolfsson and Holger Lieberwirth},

Metso Outotec to deliver energy-efficient Vertimill® grinding mills

2022年8月2日Metso Outotec to deliver energy-efficient Vertimill® grinding mills for an iron ore project in South America. From the design and supply of equipment for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help. manufacturing and supply of four Vertimill ® vertical grinding mills.

HIGmill high intensity grinding mill Metso Outotec

The Metso Outotec HIGmill™ is an advanced, energy-efficient fine and ultra-fine grinding solution that utilizes proven technology. With the tall, narrow, vertical body arrangement, grinding media is evenly distributed

Vertical mill simulation applied to iron ores

2014年11月1日The application of vertical mills in regrind circuits is consolidated. This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when...

sbm design of vertical grinding mill for iron ore fines.md main

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Sintering: A Step Between Mining Iron Ore and

2019年6月11日According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated

Iron Ore Processing, General SpringerLink

2022年10月20日Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills. Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions.

Buy Ore Ball Mill for Mineral Processing IronGold

Ore Ball Mill Output size: 0.074-0.89mm Motor power: 18.5-480kw Specification (mm): Φ750×750-Φ2700×4500 Applications: It is used for processing various grindable mineral materials, non-ferrous metal

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is

Vertical Roller Grinding Machine Roller Assembly

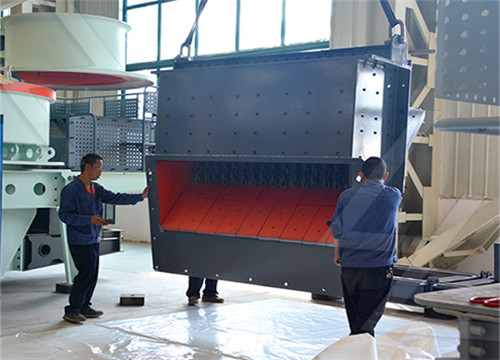

Millstone is one of the key parts of vertical mill, which is mainly composed of resistance ring, liner and base.Optimize the design of the grinding disc casting process to overcome the deficiencies of the previous structure, make the grinding disc base uniformly stressed, increase the bite angle between the grinding disc grinding rollers, and avoid brush

Investigation on Iron Ore Grinding based on Particle Size Distribution

2020年5月28日The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

BRPL Home

Iron ore fines are subjected to Beneficiation process to produce iron ore concentrates with higher iron content. The iron ore fines of -10mm size from the stockpile is conveyed to Beneficiation plant for screening through series of conveyors. The bentonite is stored and ground in a Vertical grinding mill by dry grinding process to desired