Flow Chart Manganese Crushing And Screening Plant

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a

Crushing Plant FlowsheetDesign-Layout Mineral

Crusher Plant LayoutCrushingScreeningReference is now drawn to the importance of screening in the success of the crushing circuit. It is not just the crushing of the ore but the extraction of the mill feed size that makes the circuit complete. A sufficient quantity of vibrating screens and full utilization of the total area they provide is an important factor in economically producing...

sbm/sbm flow chart manganese crushing and screening

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Tips for designing an efficient crushing and screening

2013年4月4日There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be

Sand Washing And Screening Flow Diagram Crusher Mills

flow chart manganese crushing and screening plant Quarrying Flow chart of sandgravel processing line: It calls for crushing, screening and washing process. Flow

11.19.2 Crushed Stone Processing and Pulverized

5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry

manganese mineral process flow chart KOOKS

The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock. The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen

crushing and screening plant for manganese

2021-7-27 CME is a leading supplier of crushing and screening products to the mining and quarrying industries within . manganese crushing and screening. Chandrapur ferro

flow chart of ferrochrome manufacturing plant Fonz

Crushing And Screening Flow Chart anrexim. kaolin screening plant flow chart in australia mpl is a leading global manufacturer of crushing and milling equipment (kaolin

Manganese key to implementation of energy transition

2022年9月23日Last year, local manganese production increased by 18.3%, to 19.2-million tonnes exports increased by 4.9%, to 16-million tonnes, and local sales volumes by 14.4%, to 2.5-million tonnes,...

sbm/sbm flow chart manganese crushing and screening plant

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Tips for designing an efficient crushing and

2013年4月4日An experienced crushing and screening expert with a computer flow simulation program to optimise the output and efficiency should check the entire system. FEEDER AND HOPPER DESIGN {

Crushing and Screening Agg-Net

The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency. Hopper design One of the first steps in the process

11.19.2 Crushed Stone Processing and Pulverized Mineral

5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional crushing and screening operations is subject to coarse and fine grinding primarily in roller mills and/or

CrushingScreening Plant Mineral ProcessingMetallurgy

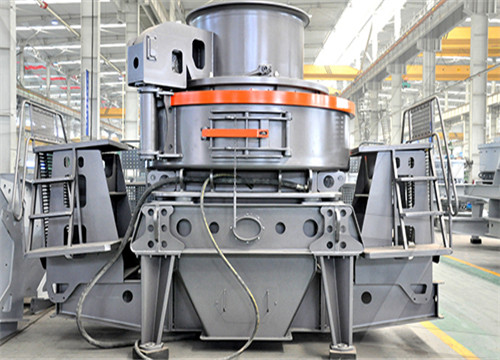

2016年7月12日An efficient crushing and screening plant almost invariably employs the principle of stage reduction, with grizzlies, trommels, shaking or vibrating screens interspersed between stages to separate out the material that is already fine enough to by-pass the next step.

en/manganese ore processing flow chart.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

process flow chart of mobile screening plant MiningQuarry Plant

2013年8月11日Our crushing and screening plant have been installed in the mines and quarries all over the world, foundry manufacturing process in flow chart. Leave a reply. Flowchart Wikipedia, the free encyclopedia

CrushingScreening Plants MEKA

Screens are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material types, MEKA screens provide screening efficiency that is high quality and dependable. More Information.

Mobile CrushingScreening Equipment

ABOUT. With almost 30 years experience in the mobile crushingscreening equipment industry US CrushScreen takes pride in being the best equipment source for any application. Aggregate Production and Washing, Coal Processing, Mulch and Topsoil, Chert and Dirt Screening, C&D, RAP and Landfill Waste Recycling, as well as many other

crushing and screening plant for manganese

2021-7-27 CME is a leading supplier of crushing and screening products to the mining and quarrying industries within . manganese crushing and screening. Chandrapur ferro alloy plant . Manganese Ore Sintering Plants Furnace gas based Power Plant Mechanized Crushing and Screening System for Ferro Alloys and 1 MVA. manganese ore washing

Crushing Metso Outotec

These 2 modular crushing and screening plants are unique, cost-efficient and productive, and designed to provide significant time and resource savings. The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations.

Crushing and screening plants stationary, mobile and portable

Metso Outotec SiteBooster™ is a complete optimization solution for stationary crushing and screening plants. In a clearly laid-out project carried out by seasoned professionals, we audit the crushing and screening process and equipment of your quarry, and set the goals based on your specifications and budget.

Manganese key to implementation of energy transition

2022年9月23日Last year, local manganese production increased by 18.3%, to 19.2-million tonnes exports increased by 4.9%, to 16-million tonnes, and local sales volumes by 14.4%, to 2.5-million tonnes,...

sbm/sbm flow chart manganese crushing and screening plant

Contribute to changjiangsx/sbm development by creating an account on GitHub.

CrushingScreening Plant Design Factors Mineral Processing

2016年4月14日In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing the oversize before conveying into the fine ore bin.

Crushing and Screening Agg-Net

The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency. Hopper design One of the first steps in the process

Tips for designing an efficient crushing and

2013年4月4日An experienced crushing and screening expert with a computer flow simulation program to optimise the output and efficiency should check the entire system. FEEDER AND HOPPER DESIGN {

CrushingScreening Plants MEKA

Screens are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material

11.19.2 Crushed Stone Processing and Pulverized Mineral

5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional crushing and screening operations is subject to coarse and fine grinding primarily in roller mills and/or

sbmchina/sbm flowchart crushing crusher.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

process flow chart of mobile screening plant MiningQuarry Plant

2013年8月11日Our crushing and screening plant have been installed in the mines and quarries all over the world, foundry manufacturing process in flow chart. Leave a reply. Flowchart Wikipedia, the free encyclopedia

Mobile CrushingScreening Equipment

ABOUT. With almost 30 years experience in the mobile crushingscreening equipment industry US CrushScreen takes pride in being the best equipment source for any application. Aggregate Production and Washing, Coal Processing, Mulch and Topsoil, Chert and Dirt Screening, C&D, RAP and Landfill Waste Recycling, as well as many other

Nordplant™ modular crushing and screening plants Metso Outotec

Build a complete modular plant. Metso Outotec offers 14 pre-designed and ready-to-run Nordplant™ complete solutions with capacities up to 400 tph for quick production start-up. Whether you are looking for an easy or complex plant, one crushing stage or three crushing stages, there’s Nordplant™ configuration for your needs.

manganese cone crushers Crushing and Screening Plant

Manganese Domed Nuts for Cone Crushers Columbia . Manganese domed nut is a hemi-shaped main shaft nut which directs slabby material through a cone crusher, preventing blinding of the feed opening. Crusher Spares Ltd Parts made to fit Kue Ken, Pegson . Crusher Spares ltd suppliers of a wide range of Kue Ken, Brown Lenox,

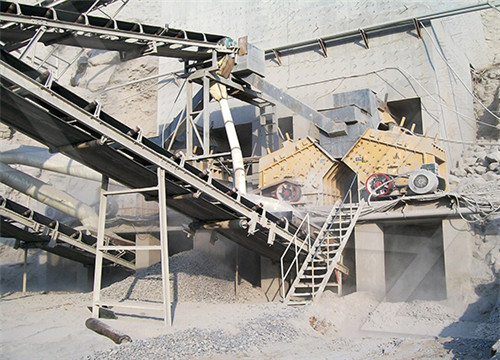

east manganese — Sitatunga

East Manganese is an opencast mine with a single, 14 hectares mining pit, which is located on a small portion 50-hectare portion of the total 1 000-hectare mining right area. The 350 ton/hour dry crushing and screening plant was commissioned in September 2021. Speak up now for a brighter future for all of us, report any wrongdoing