Principle Crusher Maintenance

Tips for Crusher Maintenance Thomasnet

2018年11月28日Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive.

进一步探索

Operation Manual For Cone CrusherCone Crusher VS Gyratory Crusher JXSC Mine根据热度为您推荐•反馈

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as

Construction Working and Maintenance of Crushers for

Construction Working and Maintenance of Crushers for Crushing Bulk

4 Types of Stone Crushers' Maintenance and Efficient

Crushers an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the

Industrial Solutions Jaw crushers ThyssenKrupp

low costs, minimum maintenance, ease of operation and maximum reliability. thyssenkrupp jaw crushers are mainly designed to crush Schematic diagram of the working

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

stockyard and the crusher is by-passed. In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日To stand up under the extremely rugged work of reducing hard and tough rock and ore, and in doing so to maintain reasonably true alignment of its running component, the crusher must necessarily be of

Roll crusher installation, operation and maintenance

2021年8月23日Reasonable maintenance and correct operation of the roll crusher can ensure long-term continuous work and reduce stopping time. Only normal management

Tips for Crusher Maintenance Thomasnet

2018年11月28日Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies every day, and make sure bolts are fastened securely. Maintain crusher

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Industrial Solutions Jaw crushers ThyssenKrupp

low costs, minimum maintenance, ease of operation and maximum reliability. thyssenkrupp jaw crushers are mainly designed to crush Schematic diagram of the working principle of a single-toggle jaw crusher with a single-toggle system Left: Single-toggle jaw crusher with main components Crusher

A Detailed Overview of Cone Crushers and What

2020年6月3日The Symons Principle Many cone crusher manufacturers use the Symons Principle to produce more powerful and efficient crushers. Based on this principle, each rotation of the mantle is timed in a way so

The Most Practical Jaw Crusher Repair and

2023年2月15日How to correctly check and maintain a jaw crusher? 1.Make a checklist Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time,

Impact crusher structure, working principle and

2021年9月2日The use of hydraulic coupling can make the motor become a light load start, reduce the torsional vibration and load pulsation during operation, and can prevent the motor and crusher from overload and

Working Principle of Crushers Mineral Processing

2016年2月17日The crusher head is at the moment in the close-side position. Crusher Working Principle. As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日To stand up under the extremely rugged work of reducing hard and tough rock and ore, and in doing so to maintain reasonably true alignment of its running component, the crusher must necessarily be of

Roll crusher installation, operation and maintenance

2021年8月23日Reasonable maintenance and correct operation of the roll crusher can ensure long-term continuous work and reduce stopping time. Only normal management and daily attention to check the working condition of roll crusher can prevent malfunction and ensure its continuous work. For this reason, the operator should pay attention to the

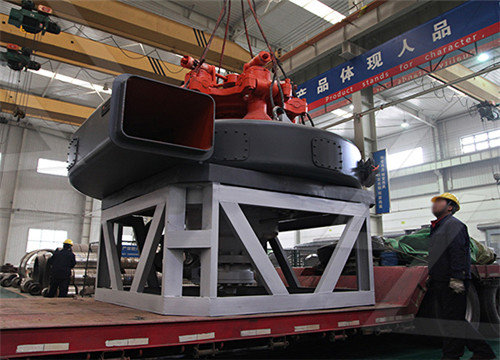

Gyratory Crusher l Introduce, Working Principle

Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall. In case of too hard or can not

Uses, Working Principles And Maintenance Of Plastic Crusher.

2021年4月15日Maintenance of crusher machine. You need to put the plastic crusher where there is ventilation this is highly needed Always check the grease level and add to it always, this allows lubricity of bearing Check the cutter regularly to ensure the screw is tight and if not screw it properly

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by liberating...

Crushers and Their Types IspatGuru

2015年4月3日The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in size. The output of the primary crusher is fed to a secondary crusher, which further reduces the size of the material.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Industrial Solutions Jaw crushers ThyssenKrupp

low costs, minimum maintenance, ease of operation and maximum reliability. thyssenkrupp jaw crushers are mainly designed to crush Schematic diagram of the working principle of a single-toggle jaw crusher with a single-toggle system Left: Single-toggle jaw crusher with main components Crusher

Crushers an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

The Most Practical Jaw Crusher Repair and

2023年2月15日How to correctly check and maintain a jaw crusher? 1.Make a checklist Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time,

Gyratory Crusher Explained saVRee

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory

Working Principle of Crushers Mineral Processing

2016年2月17日Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1.” Note that the length of

Impact crusher structure, working principle and

2021年9月2日The use of hydraulic coupling can make the motor become a light load start, reduce the torsional vibration and load pulsation during operation, and can prevent the motor and crusher from overload and

Cone Crusher Working Principle Animation

2012年8月15日Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing

Uses, Working Principles And Maintenance Of Plastic Crusher.

2021年4月15日Maintenance of crusher machine. You need to put the plastic crusher where there is ventilation this is highly needed Always check the grease level and add to it always, this allows lubricity of bearing Check the cutter regularly to ensure the screw is tight and if not screw it properly

Double Roller Crushers SolidsWiki

Operation Principle. Double roll crusher is driven by the motor through the pulley or gear shaft opposite two rollers rotate, or were driven by two motors rotate two rollers. Double roll crusher with material by weight and the friction between the roll surface into the crusher and discharge within the broken. Through changes in two double roll

Primary Gyratory Crusher Maintenance Crushing, ScreeningConveying

My questions are regarding to maintenance of the primary gyratory crushers. Does anybody know any kind of sensor to monitoring head spin of the main shaft of the primary gyratory crusher? During the measurement of the spider bushing clearance, I need to remove the spider cap and then check clearance using a feeler gauge. (Please the

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

2. WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor. It is designed to use a 3 phase induction motor for the electrical operation of the crusher as the power required