Hematite Hematite Gravity Separation Process

Gravity Separation of Zinc Mine Tailing Using Wilfley

2020年1月16日In such a way, this work aims through gravity separation to concentrate the mineral phase hematite. The Wilfley shaking table was used to process 500 g of the

Recovery of magnetite-hematite concentrate from iron ore

separation in low intensity field for magnetite recovery and gravity concentration for hematite recovery. 3 Results and discussion As it was shown above, the tailings contain

Hematite: A primary ore of iron and a pigment mineral

Hematite is found as a primary mineral and as an alteration product in igneous, metamorphic, and sedimentary rocks. It can crystallize during

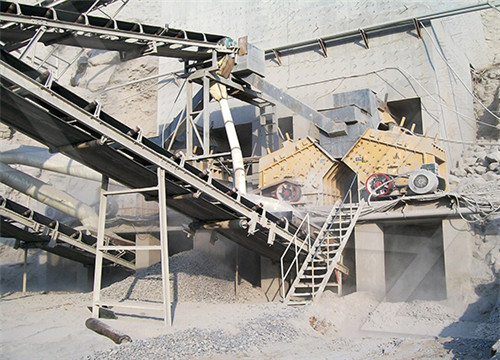

HEMATITE BENEFICIATION PROCESS, HEMATITE

2021年4月30日The hematite is easily separated from the gangue and enters the jigger for gravity beneficiation after crushing and screening. After washing, jigging, and spiral

Extraction of Iron: Meaning, Purification,Extraction

2021年9月27日Extraction of Iron from Hematite 1). Concentration. Hematite is concentrated by the gravity separation process which is a method based on the

Four Kinds of Hematite Ore Dressing Processes, Which

2019年10月24日Hematite gravity separation process mainly includes coarse grain gravity separation process and fine grain gravity separation process: Coarse grain

Hematite Separation Process Haiwang Technology

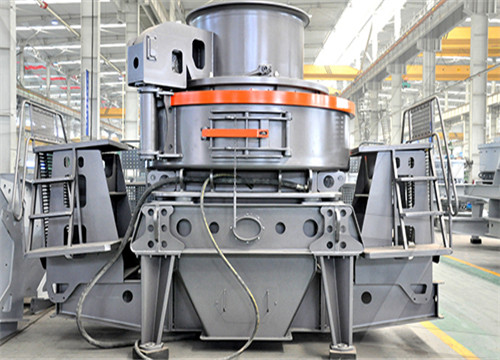

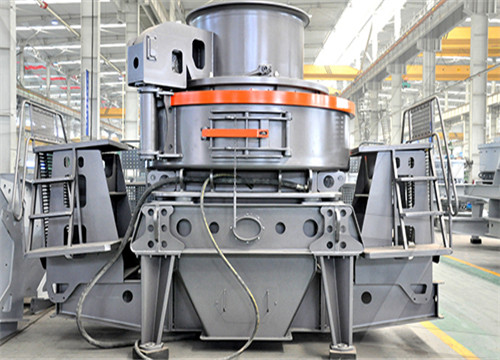

Process Description At present, hematite typical dressing process have three kind: continuous milling-week magnetic-strong magnetic-anion reverse flotation, stage grinding-coarsefine separation-gravity-magnetic

Hematite Processing by Flotation Mineral Processing

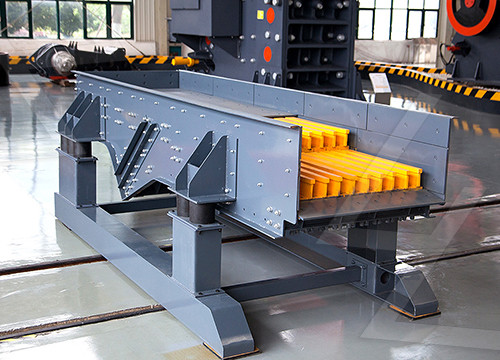

2016年4月19日Crushing Hematite Rock Three stage ore reduction is used with either a grizzly or vibrating screen between each crushing stage. Removing fines before putting the ore through a crusher increased the

Hematite Ore, Hematite Mineral, Hematite Beneficiation Process

The hematite separation processes mainly including the flotation process, magnetic separation process, gravity separation process and roasting magnetic separation

[PDF] Gravity Separation of Zinc Mine Tailing Using Wilfley

2020年1月1日The Wilfley shaking table was used to process 500 g of the tailing. Three different materials were obtained after the Separation process: Hematite concentrate, middling, and Gravity separation

Gravity Separation of Zinc Mine Tailing Using Wilfley

2020年1月16日The process generates a residue consisted of hematite and dolomite. The residue used in this work presents desegregated hematite and dolomite particles, previously identified by MEV. In such a way, this work aims through gravity separation to concentrate the mineral phase hematite. The Wilfley shaking table was used to process 500 g of the

Gravity Separation of Zinc Mine Tailing Using Wilfley

tion process: hematite concentrate, middling, and gravity separation tailing (GST). Gravity Separation of Zinc Mine Tailing Using Wilfley 349 residue is composed of Fe 7%, Mg 10.4%, Ca 19

Gravity Separation ScienceDirect

2016年1月1日The separation by gravity is based on the difference in settling rates or terminal velocities of particles of different density and size. However, with short distances of travel in some separation processes, particles may not have a chance to reach their terminal velocity.

Hematite Separation Process Haiwang Technology

At present, hematite typical dressing process have three kind: continuous milling-week magnetic-strong magnetic-anion reverse flotation, stage grinding-coarsefine separation-gravity-magnetic-anion reverse

Hematite Separation Process new.hotminingepc

Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolin.The beneficiation process includes stage grinding, coarse-fine particle

Three-phase froth stability in hematite flotation using DDA as a

Three-phase froth stability experiment. The three-phase froth stability of quartz and hematite in the presence of DDA was evaluated by aeration. The effect of hematite or quartz particles with different particle sizes (106–45, 45–18, and −18 μm) and different particle concentrations (20, 40, 60, 80, and 100 g/L) on foam stability was

Hematite Separation Process

2015年7月16日Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle,

Magnetic and Electrostatic Separation for Mineral Processing

Magnetic separation is a process that uses a magnetic field to separate magnetic minerals from non-magnetic ones. The magnetic field can be generated by a permanent magnet, an electromagnet, or a

Gravity separation process is used for the concentration of

2023年2月27日The gravity separation process uses this property for the concentration of ore. -Hematite ore is concentrated using the gravity separation process. Hematite is a common ore of iron oxide. The chemical formula for hematite is F e 2 O 3. Hematite ore is black or silver-grey in colour.

A Beneficiation Study on a Low Grade Iron Ore by Gravity and

2018年8月25日In this , a sample from Tange-zagh iron mine was characterized by gravity and magnetic separation methods. The mineralogical studies showed that hematite and goethite are the main iron-bearing minerals with insignificant amounts of FeO. The results indicated that spiral separation yields higher separation efficiency than

Hematite Processing by Flotation Mineral ProcessingMetallurgy

2016年4月19日Crushing Hematite Rock Three stage ore reduction is used with either a grizzly or vibrating screen between each crushing stage. Removing fines before putting the ore through a crusher increased the efficiency of the crusher as it is then only working on material that must be reduced.

Separation process of iron ore,iron ore magnetic separation

2020年9月8日Gravity separation process and strong magnetic separation process are mainly used to separate coarse-grained (2mm-20mm) and medium-grained weakly magnetic iron ore. Among them, coarse and extremely coarse (greater than 20mm) ores are commonly used in heavy medium or jigging gravity separation technology;

Investigations on the Reverse Flotation of Quartz/Hematite Using

2023年3月9日The adsorption morphology of pullulan on hematite was further observed by atomic force microscopy. Fig. 7a and Fig. 7b shows the AFM photographs of the hematite surface before and after the adsorption of pullulan, respectively. Fig. 7b showed the natural hematite surface with regular peaks and valleys, which were caused by the crushing

[PDF] Gravity Separation of Zinc Mine Tailing Using Wilfley

2020年1月1日The Wilfley shaking table was used to process 500 g of the tailing. Three different materials were obtained after the Separation process: Hematite concentrate, middling, and Gravity separation

Gravity Separation of Zinc Mine Tailing Using Wilfley

tion process: hematite concentrate, middling, and gravity separation tailing (GST). Gravity Separation of Zinc Mine Tailing Using Wilfley 349 residue is composed of Fe 7%, Mg 10.4%, Ca 19

Gravity Separation ScienceDirect

2016年1月1日The separation by gravity is based on the difference in settling rates or terminal velocities of particles of different density and size. However, with short distances of travel in some separation processes, particles may not have a chance to reach their terminal velocity.

Hematite Separation Process Haiwang Technology

Process Description At present, hematite typical dressing process have three kind: continuous milling-week magnetic-strong magnetic-anion reverse flotation, stage grinding-coarsefine separation-gravity-magnetic

Three-phase froth stability in hematite flotation using DDA as a

Three-phase froth stability experiment. The three-phase froth stability of quartz and hematite in the presence of DDA was evaluated by aeration. The effect of hematite or quartz particles with different particle sizes (106–45, 45–18, and −18 μm) and different particle concentrations (20, 40, 60, 80, and 100 g/L) on foam stability was

Hematite Separation Process

2015年7月16日Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle,

Hematite Processing by Flotation Mineral Processing

2016年4月19日Crushing Hematite Rock Three stage ore reduction is used with either a grizzly or vibrating screen between each crushing stage. Removing fines before putting the ore through a crusher increased the

Hematite Ore, Hematite Mineral, Hematite Beneficiation Process

The hematite separation processes mainly including the flotation process, magnetic separation process, gravity separation process and roasting magnetic separation process. 24-hour service hotline 0086 . Send us an email Hematite separation process is suitable for complex structure hematite ore, such as hematite

Magnetic and Electrostatic Separation for Mineral Processing

Magnetic separation is a process that uses a magnetic field to separate magnetic minerals from non-magnetic ones. The magnetic field can be generated by a permanent magnet, an electromagnet, or a

A Beneficiation Study on a Low Grade Iron Ore by Gravity and

2018年8月25日In this , a sample from Tange-zagh iron mine was characterized by gravity and magnetic separation methods. The mineralogical studies showed that hematite and goethite are the main iron-bearing minerals with insignificant amounts of FeO. The results indicated that spiral separation yields higher separation efficiency than

Low grade Iron Ore Beneficiation and the Process

2018年9月25日Jigging process is one of the gravity separation method in which the particles are normally of a similar size, often crushed and screened prior to being fed over the jig bed. Though there are many

How to Extract Iron from Iron Ore? Mining Pedia

2022年9月23日Hematite Roasting-Magnetic Separation Process This method is to magnetically roast hematite ore to convert hematite or martite into magnetite, and then use a weak magnetic field magnetic separator for separation. It is suitable for complex mineral components and difficult to achieve the ideal concentrate grade of hematite by other

Investigations on the Reverse Flotation of Quartz/Hematite Using

2023年3月9日The adsorption morphology of pullulan on hematite was further observed by atomic force microscopy. Fig. 7a and Fig. 7b shows the AFM photographs of the hematite surface before and after the adsorption of pullulan, respectively. Fig. 7b showed the natural hematite surface with regular peaks and valleys, which were caused by the crushing

Minerals Free Full-Text Recovery of Hematite from Banded Hematite

2022年8月29日The present study enumerates concentration efficiency (CE),which can be adopted exclusively for processing low-grade hematite ore by WHIMS—the reverse flotation route to produce a pellet grade concentrate. producing pellet-grade concentrates using gravity and magnetic separation. However, the work on the beneficiation of BHQ from