Good Efficient Coarse Mining Mill Coarse Crusher Machine

Types of Crushers: What You Need to Know Machinery Partner

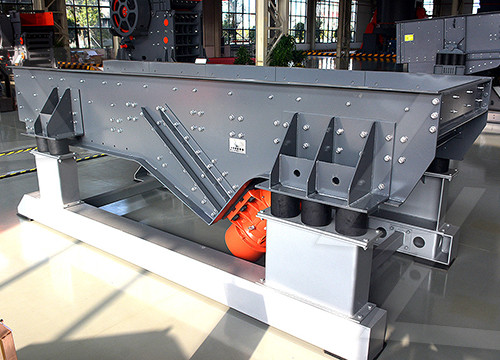

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also

进一步探索

5 Types Of Stone Crushers Application and MaintenanceUnderstanding the Different Types of Crushers Agg-NetCrushers and Their Types IspatGuruCharacteristics and Comparison of Four Types of Jaw CruDifferent types of crushers for distinctive needs Metso Out根据热度为您推荐•反馈

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller,

Coarse Jaw Crusher Crusher Mills, Cone Crusher, Jaw Crushers

Find detailed product information for High efficient coarse stone jaw crusher for quarry 750×1060 and other products from Henan Zhongke EngineeringTechnology Co

MMA mining machine,crusher,mill,sand making machine,mineral

MMA Heavy Industry specializes in the manufacture of crushers, sand making machines, pulverizers and mobile crushing stations. Crusher series: jaw crusher (jaw crusher),

Turmeric Crushing Production Line (Coarse Crusher and

2022年3月19日Turmeric crushing production line: from the raw material into the coarse crusher, and then through the mini-efficient crusher to form powder.Jiangyin Mill Po...

Coarse Powder Crusher Mills, Cone Crusher, Jaw Crushers

MXB series coarse powder Grinding mill is used to pre-crush various coarse materials. MXB grinder mill can reach up to fineness smaller than 2mm. The whole plant will

Cinnamon Crushing Production Line (Coarse Crusher and

2022年3月17日Cinnamon crushing production line: from the raw material into the coarse crusher, and then through the mini-efficient crusher to form powder.Jiangyin Mill Po...

coarse crusher ZMJ014 shenxiang (China Manufacturer) Metal

coarse crusher ZMJ014 shenxiang Products Made In China, China Manufacturer. Iron ore industrial art application Shenxiang column mill ultrfine crushing works in medium

AMIT 135: Lesson 5 Crushing Mining Mill Operator

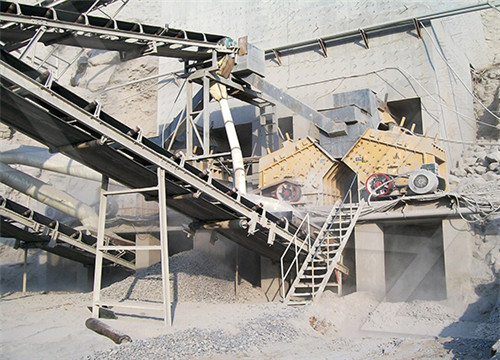

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste

Aggregates McLanahan

McLanahan’s in-house laboratory offers material testing to provide you with a machine that will fit your crushing requirements. Attrition Cells, Blade Mills, Coarse Material Screw Washers, Log Washers and Rotary Scrubbers can be used to break down and remove clay, coatings, dust, vegetation and more from a coarse aggregate feed to produce

Primary Crusher SelectionDesign Mineral Processing

2015年12月23日The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. per yard3 and having a specific gravity of 2.6. Wet, sticky and extremely hard or tough feeds will tend to reduce crusher capacities.

Types of Crushers: What You Need to Know Machinery Partner

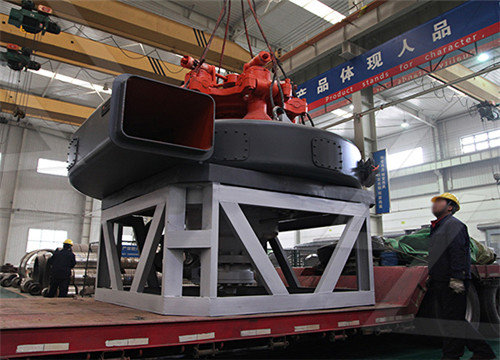

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Jaw Crushers high quality and reliability from RETSCH

Retsch. Products. Milling. Jaw Crushers. The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Benchtop Unit.

Rock Crushers Best 2023 Models 911Metallurgist

1″ x 2″ Mini Rock Crusher XRF Sample Pulveriser. US$ 6,000. Add to cart.

Crusher an overview ScienceDirect Topics

This type of crusher is used in secondary or tertiary crushing applications. Advanced roll crushers are designed with one rotating cylinder that rotates toward a fix plate or rollers with differing diameters and speeds. It improves the liberation of minerals in the crushed product.

MMA mining machine,crusher,mill,sand making machine

MMA Heavy Industry specializes in the manufacture of crushers, sand making machines, pulverizers and mobile crushing stations. Crusher series: jaw crusher (jaw crusher), cone crusher, vertical crusher and other crushing equipment. Mill: Raymond mill, trapezoidal mill, vertical mill. Tel: 400-655-1888.

Turmeric Crushing Production Line (Coarse Crusher and Mini-Efficient

2022年3月19日Turmeric crushing production line: from the raw material into the coarse crusher, and then through the mini-efficient crusher to form powder.Jiangyin Mill Po...

Cinnamon Crushing Production Line (Coarse Crusher and Mini-Efficient

2022年3月17日Mill Powder Technology 393 subscribers 2.5K views 11 months ago Cinnamon crushing production line: from the raw material into the coarse crusher, and then through the mini

Coarse Powder Crusher Mills, Cone Crusher, Jaw Crushers

Coarse Powder Mill,Coarse Powder Roller Mills for Sale,Used . Coarse powder mill manufacturer liming supplies coarse powder roller mills for sale in grinding and milling industry. Coarse Powder Mill is a kind of new high-tech milling machine to meet the requirements of coarse powder processing customers. Based on our experts’ many

mill/sbm machine for coarse slag crushing.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Roll Crusher an overview ScienceDirect Topics

The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84-inch-long (213 cm) roll crushing to pass 10 inches (25 cm).

AggregateRock Crushing Equipment Stedman Machine

RockAggregate Crushing Equipment. Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for the construction of roads, buildings, and bridges. Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, , caulking, and glass.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

Aggregates McLanahan

Attrition Cells, Blade Mills, Coarse Material Screw Washers, Log Washers and Rotary Scrubbers can be used to break down and remove clay, coatings, dust, vegetation and more from a coarse aggregate feed to produce a clean, sound aggregate product. Types of Aggregate Scrubbing Equipment Attrition Cells/Scrubbers Blade Mills

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Jaw Crushers high quality and reliability from RETSCH

Retsch. Products. Milling. Jaw Crushers. The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Benchtop Unit.

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty

Rock Crushers Best 2023 Models 911Metallurgist

1″ x 2″ Mini Rock Crusher XRF Sample Pulveriser. US$ 6,000. Add to cart.

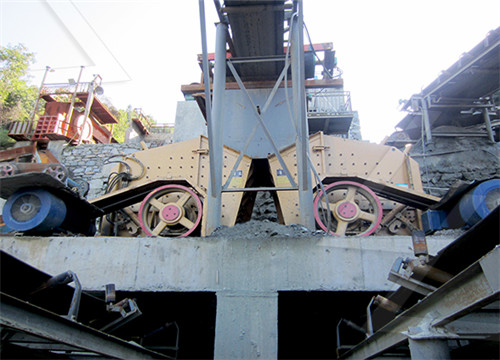

Hammer Mill CrusherGrinder Mineral ProcessingMetallurgy

2016年2月25日The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and

Coarse Powder Crusher Mills, Cone Crusher, Jaw Crushers

Coarse Powder Mill,Coarse Powder Roller Mills for Sale,Used . Coarse powder mill manufacturer liming supplies coarse powder roller mills for sale in grinding and milling industry. Coarse Powder Mill is a kind of new high-tech milling machine to meet the requirements of coarse powder processing customers. Based on our experts’ many

Cinnamon Crushing Production Line (Coarse Crusher and Mini-Efficient

2022年3月17日Mill Powder Technology 393 subscribers 2.5K views 11 months ago Cinnamon crushing production line: from the raw material into the coarse crusher, and then through the mini

Coarse Powder Hammer Mill Grinder For Sale, Hammer Mill Crusher Machine

Hammer Mill. HM Series Coarse Powder Mill is one kind of new high efficient grinding machine. This mill is mainly used for coarse powder and small size of sand producing. The output size can reach more than 90% of 0-3mm, It is used for processing coarse powder particles. Feed particle size: 0-50mm Production capacity: 3-50 tons / hour

mill/sbm good quality cheapest efficient mining cone crusher

Contribute to crush2022/mill development by creating an account on GitHub.

mill/sbm machine for coarse slag crushing.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Rock Grinder Machine Crusher Mills, Cone Crusher, Jaw Crushers

Amazon: CAB KING 8" lapidary rock grinding polishing . This is a complete machine. You start out at 80 grit and finish on the polishing pad with cerium oxide at about 30,000 grit 3/4 hp, 110v, 1800 rpm, 60hz motor, A 605 .

Roll Crusher an overview ScienceDirect Topics

Although not widely used in the minerals industry, roll crushers can be effective in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum, phosphate, and soft iron ores.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Semi-Autogenous Grinding (SAG) Mill Wet or dry Higher capacity than A-G mill grinding Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 4-12% ball charge (ball dia.100- 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material) Semi-Autogenous Mill