Bronze Worm Gear Crusher Machines

Worm Gearing Design Standards, Proportions, and Materials

2 之The S.A.E. nickel phosphor gear bronze (No. 65 + Ni) contains 87% copper, 11% tin, 2% nickel and 0.2% phosphorous. Single-thread

Worm Gears Open Gearing Products Boston Gear

根据热度为您推荐•反馈

Custom Gear Blanks US Bronze FoundryMachine, Inc.

We produce gear worm blanks with centrifugal and static casting techniques. Built-in automation and controls ensure heightened precision and quality. The ability to

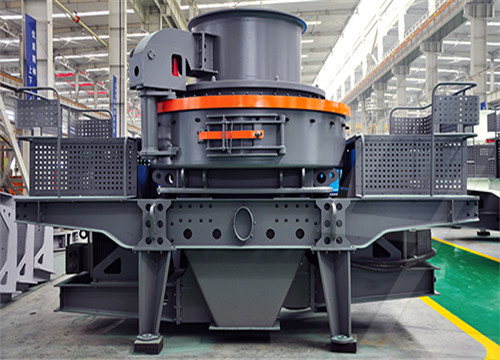

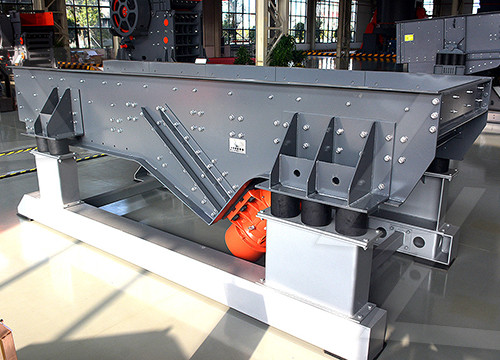

Industrial Crusher PartsCrusher Castings Manufacturer

As a leading industrial crusher parts manufacturer, we produce cast parts of all sizes. Our specialty is large cast products tailored to client specifications. We utilize static and

All About Worm Gears What They Are and How They

2 之Worm gears are power-transmission components primarily used as high-ratio reductions to change the direction of shaft rotation and to decrease speed and increase

Bronze Gears McMaster-Carr

These worms are compatible with plastic worm gears. Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases. Bronze gears

How to Make Bronze for Worm Gear Applications ASI

2018年9月5日Typically, for worm gears, we recommend tin bronze (C91700) and aluminum bronze (C95400 and C95500) due to their relatively high strength, and

Bronze Worm Gear Timing Pulley

Common Bronze Worm Gear Applications The high torque output of worm gears makes them ideal for heavily loaded machinery. Some of the most typical applications for worm

worm gear Phosphor Bronze Worm Gear Manufacturer from

worm gear worm gear We are a leading Manufacturer of phosphor bronze worm gear from New Delhi, India. Get CALLBACK Phosphor Bronze Worm Gear Get Best Quote

WormWorm Gears Crusher Applications Mining Boston Gear

Boston Gear offers worm gears manufactured from a variety of materials, such as acetal, minlon, bronze, and cast iron to suit your application's requirements. Note: Because the efficiency of a worm gear drive depends on the lead angle and number of starts on the worm, the ratio should be kept low.

Gear Materials, Classification and Application Thomasnet

1 Worm Gears: For bronze worm gears, two alternative analyses of phosphor bronze are recommended, SAE No. 65 and No. 63. SAE No. 65 (called phosphor gear bronze) has the following composition: Copper, 88 to 90; tin, 10 to 12; phosphorus, 0.1 to 0.3; lead, zinc, and impurities (max) 0.5 percent. Materials for Worm Gearing. The

Worm Gears Open Gearing Products Boston Gear

Boston Gear offers worm gears manufactured from a variety of materials, such as acetal, minlon, bronze, and cast iron to suit your application's requirements. Note: Because the efficiency of a worm gear drive depends on the lead angle and number of starts on the worm, the ratio should be kept low.

Manufacturing Single-Envelope Worm Gears Gear Solutions

2003年4月1日A bronze worm wheel is more ductile, with a lower coefficient of friction. For worm sets operated at low speed, or in high-temperature applications, cast iron may be used for the worm wheel. The worm goes through many more contact stress cycles than the worm wheel, so it is advantageous to use the harder, more durable material for the

The Effects of EP Additives on Gearboxes Machinery Lubrication

These machines have gearing composed of yellow metal (typically bronze). Certain extreme pressure (EP) additives can chemically react with these softer metals, causing premature wear and even failure. Worm gearboxes are mainly comprised of two units: the worm and the worm wheel. The worm is what actually drives the worm wheel.

Worm Gear Reducer Common Problems and Solutions

2019年10月27日The worm gear is generally made of tin bronze. The paired worm material is generally hardened with 45 steel to HRC45-55. It is also commonly used 40Cr: hardened HRC50-55, ground to the roughness RaO.8fcm by the worm grinder, and the worm is in the normal operation of the gearbox. Worm gear reducer solution to other

Industrial Crusher PartsCrusher Castings Manufacturer US Bronze

As a leading industrial crusher parts manufacturer, we produce cast parts of all sizes. Our specialty is large cast products tailored to client specifications. We utilize static and centrifugal casting techniques and have the following capabilities: Castings up to 35,000 pounds. Lengths of up to 80 inches for centrifugally cast parts.

Finding the ideal materials for gears Gear Solutions Magazine

2021年1月15日The most common stainless steel is 304 alloy. It contains 18% chromium and 8% nickel. For gearing, 303 stainless is typically used. In 303 alloy, the chromium content is reduced to 17%, and 1% of the alloy is sulfur. Because of the addition of the sulfur, 303 alloy has improved machinability compared to 304 alloy.

How to Make Bronze for Worm Gear Applications ASI

2018年9月5日Typically, for worm gears, we recommend tin bronze (C91700) and aluminum bronze (C95400 and C95500) due to their relatively high strength, and superior fatigue, friction, and wear resistance. The process of making bronze involves first heating the copper element to a specified temperature. Once the copper reaches a molten state,

Gears Look to the Future for Material Machine Design

2015年12月8日Phosphor bronze centrifugal cast has a BHN of 90 N/mm 2. AISI 9310 is a case-hardened steel alloy at 300°F used for aerospace gears that experience high loads and operate at high pitch line

All About Worm Gears What They Are and How They Work

2 之Worm gears are power-transmission components primarily used as high-ratio reductions to change the direction of shaft rotation and to decrease speed and increase torque between non-parallel rotating shafts. They are used on shafts with non-intersecting, perpendicular axes. Because the teeth of the meshing gears slide past each other,

Machine Screw Jack and Accessories Nook Industries

Machine Screw Jack. Standard model capacities from 1/4 ton to 100 tons. Metric capacities from 5 kN to 200 kN. The Inch and Metric Worm Gear Machine Screw Jacks incorporate an alloy or stainless steel worm which drives a high strength bronze worm gear (drive sleeve). The worm shaft is supported on anti-friction tapered roller bearings with

Metallurgical Analysis of Premature Failure of a Phosphor Bronze Worm

2018年10月29日Worm drives are commonly used where large reduction in speed and greater transfer of torque are required within a small space. Phosphor bronze is normally used material for this application owing to its lower coefficient of friction and good wear and fatigue properties. This work presents a failure analysis of a worm wheel. Analysis

Bronze Gears McMaster-Carr

These worms are compatible with plastic worm gears. Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases. Bronze gears have low friction and dissipate heat better than cast iron gears to provide a long service life for both the gear and the worm.

WormWorm Gears Crusher Applications Mining Boston Gear

Boston Gear offers worm gears manufactured from a variety of materials, such as acetal, minlon, bronze, and cast iron to suit your application's requirements. Note: Because the efficiency of a worm gear drive depends on the lead angle and number of starts on the worm, the ratio should be kept low.

Gear Materials, Classification and Application Thomasnet

1 Worm Gears: For bronze worm gears, two alternative analyses of phosphor bronze are recommended, SAE No. 65 and No. 63. SAE No. 65 (called phosphor gear bronze) has the following composition: Copper, 88 to 90; tin, 10 to 12; phosphorus, 0.1 to 0.3; lead, zinc, and impurities (max) 0.5 percent.

Manufacturing Single-Envelope Worm Gears Gear Solutions

2003年4月1日A bronze worm wheel is more ductile, with a lower coefficient of friction. For worm sets operated at low speed, or in high-temperature applications, cast iron may be used for the worm wheel. The worm goes through many more contact stress cycles than the worm wheel, so it is advantageous to use the harder, more durable material for the

The Effects of EP Additives on Gearboxes Machinery Lubrication

These machines have gearing composed of yellow metal (typically bronze). Certain extreme pressure (EP) additives can chemically react with these softer metals, causing premature wear and even failure. Worm gearboxes are mainly comprised of two units: the worm and the worm wheel. The worm is what actually drives the worm wheel.

The Right Way to Lubricate Worm Gears Machinery Lubrication

Worm Gear Designs. A worm gear is a non-parallel, non-intersecting axis design consisting primarily of two gear elements: the worm, which is the driving gear in the shape of a spiral or screw, and the worm gear or worm wheel, which is the driven gear in the shape of a common spur gear. Technically, the entire worm gear system should be called a

Finding the ideal materials for gears Gear Solutions Magazine

2021年1月15日The most common stainless steel is 304 alloy. It contains 18% chromium and 8% nickel. For gearing, 303 stainless is typically used. In 303 alloy, the chromium content is reduced to 17%, and 1% of the alloy is sulfur. Because of the addition of the sulfur, 303 alloy has improved machinability compared to 304 alloy.

Industrial Crusher PartsCrusher Castings Manufacturer US Bronze

As a trusted crusher castings manufacturer, U.S. Bronze FoundryMachine helps you select the best metal alloys for your application. Those we use regularly include: Bronze And Highly Leaded Bronze Copper Stainless Steel Aluminum Nickel Other metal alloys are available upon request. Crushing solutions that stand up to what’s thrown at them

Gears Look to the Future for Material Machine Design

2015年12月8日Phosphor bronze centrifugal cast has a BHN of 90 N/mm 2. AISI 9310 is a case-hardened steel alloy at 300°F used for aerospace gears that experience high loads and operate at high pitch line

Worm Gear Reducer Common Problems and Solutions

2019年10月27日The worm gear is generally made of tin bronze. The paired worm material is generally hardened with 45 steel to HRC45-55. It is also commonly used 40Cr: hardened HRC50-55, ground to the roughness RaO.8fcm by the worm grinder, and the worm is in the normal operation of the gearbox. Worm gear reducer solution to other

How to Make Bronze for Worm Gear Applications ASI

2018年9月5日Typically, for worm gears, we recommend tin bronze (C91700) and aluminum bronze (C95400 and C95500) due to their relatively high strength, and superior fatigue, friction, and wear resistance. The process of making bronze involves first heating the copper element to a specified temperature. Once the copper reaches a molten state,

All About Worm Gears What They Are and How They Work

2 之Worm gears are power-transmission components primarily used as high-ratio reductions to change the direction of shaft rotation and to decrease speed and increase torque between non-parallel rotating shafts. They are used on shafts with non-intersecting, perpendicular axes.

Machine Screw Jack and Accessories Nook Industries

Worm Gear Machine Screw Jacks Machine Screw Jack Standard model capacities from 1/4 ton to 100 tons. Metric capacities from 5 kN to 200 kN. The Inch and Metric Worm Gear Machine Screw Jacks incorporate an alloy or stainless steel worm which drives a high strength bronze worm gear (drive sleeve).

Metallurgical Analysis of Premature Failure of a Phosphor Bronze Worm

2018年10月29日Phosphor bronze is normally used material for this application owing to its lower coefficient of friction and good wear and fatigue properties. This work presents a failure analysis of a worm wheel. Analysis revealed that around 40% of the teeth of worm wheel were broken.

Quality Cone Crusher Spare PartsCrusher Machine Spare Parts

CNC Milling Machine Worm And Worm Gear High Precision Small Size; Precision Machining Copper Wear Plate For Cone Crusher Machine Cone crusher bronze friction plate, ISO 9001 and 20 years casting experience, Chinese centrifugal casting and metal casting bronze bearing, Bush, sleeve, customized crusher parts, mining casting Our