Machine Installation Crusher

Crushing Equipment Superior Industries U.S.

CrushingScreening Equipment Product Handbook ? Liberty ® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm) Product Size 15″

Stedman Machine Industrial Crushing Equipment

Stedman Machine has the experience, expertise, and equipment to provide and install your ideal size-reduction solution. ReplacementUpgrades Stedman is the affordable option

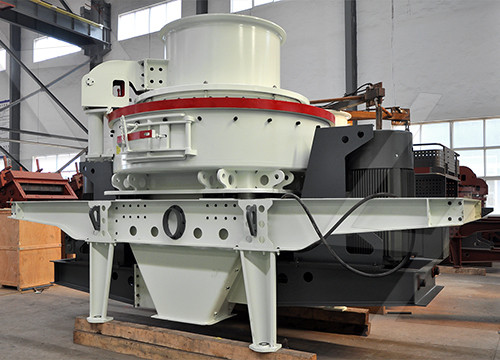

Crusher Machine Manufacturer Propel Industries

The AVC Series of Propel Cone Crusher offers the higher crushing efficiency and end product quality with lower cost per ton production. These crushers feature a unique...

进一步探索

4 Types of Stone Crushers' Maintenance and Efficient ImprCrusher Machine For Sale Types Of Crushing Machines A根据热度为您推荐•反馈

Crusher Bucket for excavators MB Crusher

The MB Crusher Bucket designed for excavators from 11,000 to 220,500 lb, transforms your heavy equipment into a real crusher. Find out how. When installed on a carrier machine, the padding buckets process

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used

Industrial Solutions Jaw crushers ThyssenKrupp

• Easy adjustment of the crushing gap using a hand-operated hydraulic device and shim plates or automatic adjust ment of the crushing gap • Crushers can be used as

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

Crusher inspections Metso Outotec

Our expert technicians are equipped with the right tools and trained to perform crusher inspections in the safest way. They can perform simple safety and surroundings inspections or do more thorough audits with

Machine Installation Manuals Crusher Mills, Cone Crusher, Jaw

Machine Installation Manuals InstallationMaintenance Haws Corporation For over 103 years, Haws has been committed to bringing the highest quality water delivery and

Crusher Bucket for excavators MB Crusher

Perfect for on-site crushing of inert materials and the first one of its kind to be introduced on the market, the MB Crusher Bucket is a piece of equipment that works by taking advantage of the hydraulic system of the

Rock Crusher MachinesPulverizers Williams Crusher

A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of the most common types of aggregates in rock crushing are sandstone, gravel, and limestone.

Industrial Solutions Jaw crushers ThyssenKrupp

• Easy adjustment of the crushing gap using a hand-operated hydraulic device and shim plates or automatic adjust ment of the crushing gap • Crushers can be used as stationary crushers or they can be integrated into wheel-mounted or track-mounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest.

Crusher Machine With The Most Reasonable Price

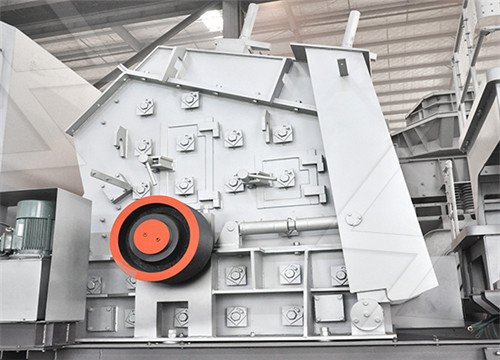

As one of the most professional crusher machine manufacturers, Aimix’s hydraulic crushing machine has many performance advantages. 1. It has a large crushing ratio and high production efficiency. 2. It uses thin oil to

Crusher Machine For Sale Types Of Crushing Machines AIMIX

What is crushing machine? It is used to crush various rocks, AIMIX, as one of the most reliable crusher machine suppliers, can provide you with a variety of crusher machines for sale, including large crusher plant for sale or small crushers.

Construction EquipmentMachinery Used in

Hydraulic-driven stone crusher is mostly used for crushing and screening in many applications, such as road construction, bridge construction, building, mining, metallurgical and energy industries, etc. Commonly

Mechanical Safety: Machinery Hazards and Control

2023年1月4日First, make sure to read the owner’s manual and follow all instructions. Second, perform regular visual inspections of all machines. Finally, keep all machines clean and free of dust and debris. By taking

COMMISSIONING and FINAL INSTALLATION REPORT

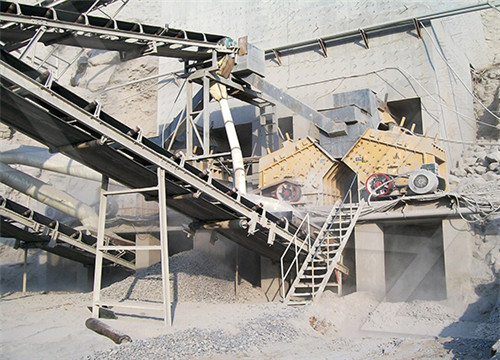

Three main bodies were involved in the installation and commissioning of the overall project. 6.1 High Voltage Engineering Europa HVEE was contracted to supply, install and commission the accelerator as supplied by them. An acceptance test with parameters agreed to by ANSTO and HVEE was performed after commissioning to allow HVEE to

Installation process of the metal shredder equipment

Install the crusher and the motor on the base made of I-shaped steel. The pulley groove of the main machine and the pulley of the motor should be consistent, and the outer end surface of the pulley should be on the same plane. In this case There is a basis for activities. When loading, you should stand on one side of the shredder or choose a

How to install crusher?

2023年1月13日Assemble the crusher: Follow the manufacturer's instructions to assemble the stone crusher. Make sure all bolts and nuts are tight and that the machine is properly aligned. Connect the power

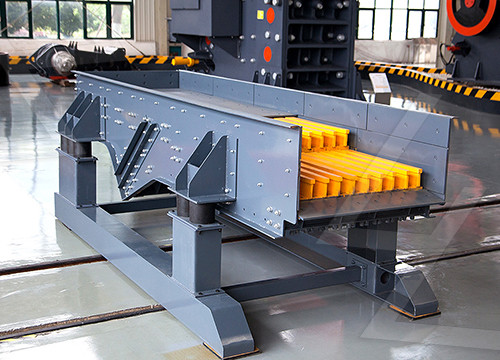

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

secondary crushers handling course materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing.

All crusher types for your reduction needs Metso Outotec

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need.

How to install a secondary crusher?

2023年1月15日Install the crusher: Set the crusher on the base and align it with the anchor bolts. Use a crane to lift the crusher into place. Connect the electrical and plumbing: Connect the crusher to the

MB CRUSHER

MB Crusher is present all over the world. 8 Branch offices support the headquarters with promoting our products and assisting our customers in all 5 continents. With a dealer network of more than 230 locations we are able to distribute MB Crusher products to more than 150 countries.

Crusher Bucket for excavators MB Crusher

Perfect for on-site crushing of inert materials and the first one of its kind to be introduced on the market, the MB Crusher Bucket is a piece of equipment that works by taking advantage of the hydraulic system of the

Industrial Solutions Jaw crushers ThyssenKrupp

• Easy adjustment of the crushing gap using a hand-operated hydraulic device and shim plates or automatic adjust ment of the crushing gap • Crushers can be used as stationary crushers or they can be integrated into wheel-mounted or track-mounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest.

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日You can install a spring anti-loosening and vibration reduction device to prolong the service life of the crushing plate. Throttling feed can maximize the production capacity and ensure that the particles

Construction EquipmentMachinery Used in

Hydraulic-driven stone crusher is mostly used for crushing and screening in many applications, such as road construction, bridge construction, building, mining, metallurgical and energy industries, etc. Commonly

Mechanical Safety: Machinery Hazards and Control

2023年1月4日The following are some common hazards associated with machinery: 1. Crushing Hazards On construction sites, crushing hazards are often caused by excavators and other heavy machinery. If an

How to install crusher?

2023年1月13日Connect the power source: Connect the stone crusher to a power source, such as a generator or electrical outlet. Make sure the machine is properly grounded. Test the crusher: Turn on the...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

secondary crushers handling course materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing.

Installation process of the metal shredder equipment

Install the crusher and the motor on the base made of I-shaped steel. The pulley groove of the main machine and the pulley of the motor should be consistent, and the outer end surface of the pulley should be on the same plane. In this case There is a basis for activities. When loading, you should stand on one side of the shredder or choose a

How to install a secondary crusher?

2023年1月15日Install the crusher: Set the crusher on the base and align it with the anchor bolts. Use a crane to lift the crusher into place. Connect the electrical and plumbing: Connect the crusher to the

Tips for Crusher Maintenance Thomasnet

2018年11月28日Check balance cylinder (s) every 30 days of operation. Keep oil and lubrication clean. Check daily, every 8 hours. Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis.

Stedman Machine Industrial Crushing EquipmentPulverizing

Stedman Machine has the experience, expertise, and equipment to provide and install your ideal size-reduction solution. ReplacementUpgrades Stedman is the affordable option for purchasing dependable, high-quality replacement wear parts and castings for multiple types of crushing equipment.

Understanding the Different Types of Crushers Agg-Net

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the setting between the two pieces of steel. Though the chamber is round in shape, the moving piece of steel is not meant to rotate.