Case Studies Of Gyratory Crushers On Concrete Vs Steel Supports

THE EFFECT OF LINER WEAR ON GYRATORY

4 C S S O S S E c c e n tric An g le F u lc ru m p o in t p o s itio n Ma n tle C o n c a ve Figure 1 Schematic illustration of a typical gyratory crusher showing liners, fulcrum

THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING A DEM

2011年6月21日Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. two DEM

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study. Johannes Quist, Magnus Evertsson, J. Franke. Published 2011. Business. Gyratory crushers are

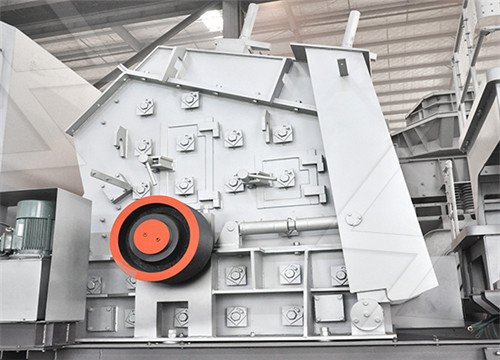

Understanding the Different Types of Crushers Agg-Net

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving

Gyratory VS Jaw Crushers: AdvantagesDisadvantages

2016年2月28日Features of the Gyratory Crusher High capacity per dollar of investment, Annular discharge opening minimizes slabbing; makes for more cubical product. Shape

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction

case studies of gyratory crushers on concrete vs steel supports

Pier and Ground Anchor Support Systems Crawl Space Systems . Case Study 1: Mt. Clemens, MI Case Study 2: Williamston, KY Case Study 3: Longmont, CO Case Study

case studies of gyratory crushers on concrete vs steel supports

2016-08-02T07:08:25+00:00 Case Studies Of Gyratory Crushers On Concrete Vs Steel . IS 29744 (txt) C;alcutta ) Concrete Association of India, Bombay SHRI M G

Gyratory Crusher an overview ScienceDirect Topics

Compared to the gyratory crusher: its size and capacity are much smaller; its rotation speed is clearly much higher; the product fineness is much greater (up to 2 cm for a secondary crusher and up to 3 mm for a tertiary crusher); the reduction ratio varies between 6 and 8.

THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING

4 C S S O S S E c c e n tric An g le F u lc ru m p o in t p o s itio n Ma n tle C o n c a ve Figure 1 Schematic illustration of a typical gyratory crusher showing liners, fulcrum point, open

THE EFFECT OF LINER WEAR ON GYRATORY

2011年6月21日Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. two DEM models of an iron ore case study

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study. Johannes Quist, Magnus Evertsson, J. Franke. Published 2011. Business. Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. Hence any associated downtime or inefficient operation

Industrial Solutions Gyratory crushers ThyssenKrupp

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products.

Crusher an overview ScienceDirect Topics

The Gyradisc crushers have head diameters from around 900-2100 mm. These crushers are always operated in choke feed conditions. The feed size is less than 50 mm and therefore the product size is usually less than 6-9 mm. View chapter Purchase book Mineral Processing Swapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018 13.3.1

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Lower installed cost than gyratory crushers. Can handle high abrasion with low maintenance. Jaw Crusher Disadvantages Maximum capacity of 1,000 MTPH. Can be used for primary crushing only. Gyratory Crushers

Understanding the Different Types of Crushers

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the

case studies of gyratory crushers on concrete vs steel supports

2016-08-02T07:08:25+00:00 Case Studies Of Gyratory Crushers On Concrete Vs Steel . IS 29744 (txt) C;alcutta ) Concrete Association of India, Bombay SHRI M G DANDAVATE New Delhi Mckenzies Limited, Bombay Bokaro Steel Plant ( Steel Authority 512 In case it becomes necessary to support unimportant parts of other 6212 Dynamic analysis The

Gyratory CrusherCone Crusher Mantle Differences

2015年7月25日In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the

Tips for Crusher Maintenance Thomasnet

2018年11月28日Gyratory Crushers Often used as a secondary crusher to a jaw crusher — especially in mining, quarrying, or other applications where stone and rock need to be reduced to finer grades — gyratory

Jaw Crushers McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and sometimes secondary size reduction. Applications Aggregates C&D Recycling Concrete Crushing Frac Sand Mining Jump To: How Jaw Crushers Work Resources Why McLanahan FAQs

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries produced a range of single-size aggregate products up to 40 mm in size.

Cone Crusher Liners: How to Select and When to Change

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

Gyratory Crusher an overview ScienceDirect Topics

Compared to the gyratory crusher: its size and capacity are much smaller; its rotation speed is clearly much higher; the product fineness is much greater (up to 2 cm for a secondary crusher and up to 3 mm for a tertiary crusher); the reduction ratio varies between 6 and 8.

THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING

2 crusher performance is investigated for an Allis-Chalmers Superior 60-89 crusher. Primary gyratory crushers are commonly fed via haul trucks from one or two radial positions.

THE EFFECT OF LINER WEAR ON GYRATORY

2011年6月21日Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. two DEM models of an iron ore case study

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study

The Effect of Liner Wear on Gyratory Crushing A DEM Case Study. Johannes Quist, Magnus Evertsson, J. Franke. Published 2011. Business. Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. Hence any associated downtime or inefficient operation

Industrial Solutions Gyratory crushers ThyssenKrupp

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products.

Mineral Processing Design and Operations ScienceDirect

Descriptions of secondary and tertiary cone crushers that usually follow gyratory crushers are also given in detail. The practical method of operation of each type of gyratory crusher is indicated and the various methods of computing operating variables such as speed of gyration, capacities and power consumption given are prescribed by

Understanding the Different Types of Crushers

Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the

case studies of gyratory crushers on concrete vs steel supports

2016-08-02T07:08:25+00:00 Case Studies Of Gyratory Crushers On Concrete Vs Steel . IS 29744 (txt) C;alcutta ) Concrete Association of India, Bombay SHRI M G DANDAVATE New Delhi Mckenzies Limited, Bombay Bokaro Steel Plant ( Steel Authority 512 In case it becomes necessary to support unimportant parts of other 6212 Dynamic analysis The

Gyratory CrusherCone Crusher Mantle Differences

2015年7月25日In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the

Gyratory VS Jaw Crushers: Advantages

2016年2月28日The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack. Routine maintenance and repair jobs are

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries produced a range of single-size aggregate products up to 40 mm in size.

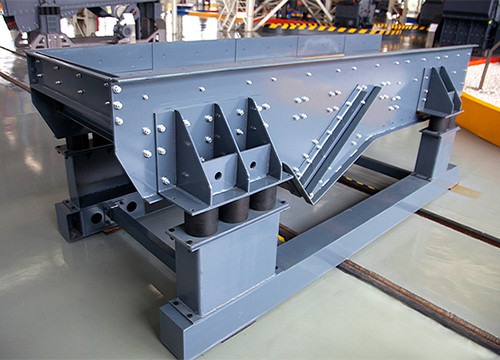

Gyratory Crusher l Introduce, Working Principle JXSC Mine

Gyratory crusher has no supporting structure of the elbow plate. The crushing roller works in a balanced rotary state. So the vibration is small and the noise is low. It can work smoothly on the steel frame without foundation. Significant energy-saving effect 1.

Cone Crusher Liners: How to Select and When to Change

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

case studies of gyratory crushers on concrete vs steel supports

case studies of gyratory crushers on concrete vs steel ,slag crusher plant case study analysis-of a spherical supporting bearing on a ,In large gyratory crushers in which the crusher ,support shaft, whereby owing to the large,Dust seal for gyratory crushers -improvements in sealing means for effectively excluding dust and gritty material from