Asphalt Aggregate Crusher Plant Process

11.19.2 Crushed Stone Processing and Pulverized

11.19.2.1 Process Description 24, 25 Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50

11.19.1 Sand And Gravel Processing US EPA

11.19.1.1 Process Description1-6 produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although

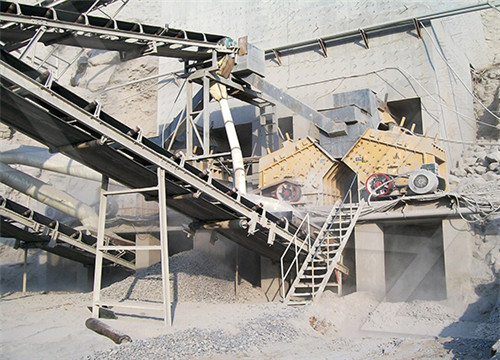

Construction Aggregate Crushing Plant

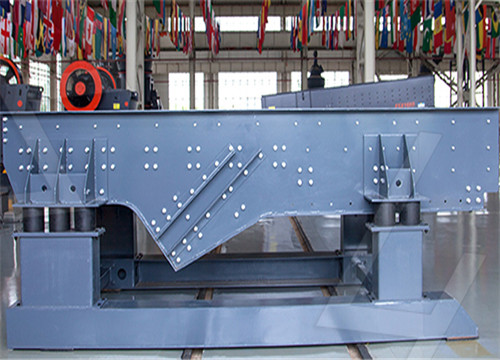

The aggregate process consists by progressive stages of crushing, screening, and washing. Aggregate production line manufactured by aims for producing

How an Asphalt Plant Works YouTube

2020年11月11日How an Asphalt Plant Works Duval Asphalt 2.29K subscribers Subscribe 558K views 2 years ago Go behind the scenes and follow the process of making hot mix asphalt at an asphalt

CrushingScreening Rentals Cat Rental Store

Choose a track crusher rental if you need to crush quarry rock or recyclable materials like concrete and asphalt. Select a screening plant rental if your project calls for screening

Aggregate Crushing Plant AIMIX Group

The material is uniformly transported into the crusher through the feeder, and after the crusher is initially broken, the closed circuit system is formed by the circular vibrating

Asphalt Batch Mix Plant Operation and Components Atlas

2017年10月7日Asphalt plants. The main components and operation of asphalt batch mix plant. It is to produce HMA known as Asphalt Batching Plant and hot mix plant. It

Chapter 2 Asphalt and Asphalt Paving Materials APAI

Table 2-2 acts as a guide to uses of asphalt in cold mixes. For additional information on asphalt and asphalt paving materials, refer to The Asphalt Handbook. Other references

(PDF) Production and Uses of Crushed Rock Aggregate

2021年10月3日The rocks will then be transported to the rock crusher, which begins the process of crushing the larger . the smaller capacity mobile plant works best for

Best Practices for Crushing, Screening RAP for HMA

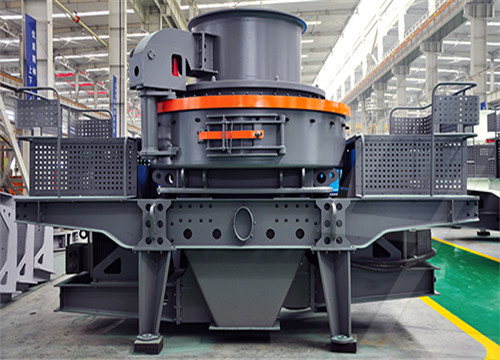

A jaw crusher in a RAP circuit is used for primary reduction, prepping it for the cone and requiring at least two crushers, and in some instances, a vertical shaft impactor (VSI) to make a spec product. An impactor in most

11.19.2 Crushed Stone Processing and Pulverized Mineral

11.19.2.1 Process Description 24, 25 Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the tertiary In dry processing systems, the mineral aggregate material from conventional crushing

(PDF) Production and Uses of Crushed Rock Aggregate from

2021年10月3日The rocks will then be transported to the rock crusher, which begins the process of crushing the larger . the smaller capacity mobile plant works best for asphalt-aggregate recycling. The

11.19.1 Sand And Gravel Processing US EPA

11.19.1.1 Process Description1-6 produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although three-stage crushing may also be performed. At some plants, after initial crushing and screening, a portion of the sand may be diverted to construction sand use.

ASPHALT PRODUCTION PROCESS Polygonmach

2022年4月21日The aggregates are dried in a dryer at a temperature of 145-160°C and then mixed with the bitumen heated at 155-160°C in a mixer. Additives such as fillers and stone mastic can also be added to the mixture. Each batch mixing time is approximately 45 seconds. Bitumen and aggregate must be completely homogenized with each other.

Machines Free Full-Text Developing and Testing of the Principle

In the current recycling process of reclaimed asphalt pavement (RAP), due to the serious damage of aggregate gradation and the large amount of aged asphalt still wrapped around the surface of the treated aggregate, the low recycling rate and poor performance of the recycled asphalt mixture are the major problems of RAP. In view of the shortcomings of

What should I know about a crusher plant? linkedin

2023年3月2日Crusher plants are used in aggregate production, mining, recycling, and in many other industrial processes. They are used to process materials such as rocks, ores, and other aggregates for...

Abdulraman S.O and Olaleye B IJSER

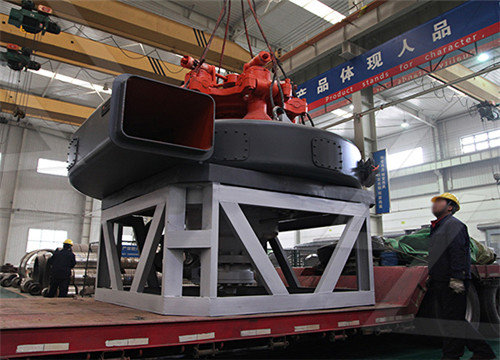

Key words: Cash flow, crushing plant, quarry products, vertical shaft impactor —————————— —————————— 1.0 INTRODUCTION 1.1 Aggregate Quarrying Process and Quarry Products Granite aggregate quarrying is a multistage process by which granite rock deposit is extracted from the ground and crushed to

Life Cycle Assessment of Greenhouse Gas Emissions from Recycled Asphalt

With the growing impact of climate change, there is an increasing need and obligation to reduce the responsible greenhouse gases (GHG) in road construction as well. Using life cycle assessment (LCA) methods, several studies have already separately analysed individual parameters of the asphalt production process and illustrated potential

Turning the water off on aggregate washing with RCAS Quarry

2023年3月9日This principle is embedded in Kayasand’s flagship V7 crushing and screening plant. It is designed to produce accurately graded concrete sand from any type of aggregate material. “We [at Kayasand] see a future where quarries can turn off the water on their aggregate washing process and replace it with dry systems that transform waste

production process of aggregates MiningQuarry Plant

2013年3月7日NW Process Equipment specializes in production, automation, weighing and control equipment and systems for asphalt, aggregate and concrete plants. Karl Marx theory of the mode of Production as a cyclical

Al-Shalawi International Co. For TradingContracting

Aggregate Crusher plants. We apply stringent process control norms to ensure that quality products are delivered to customers and to our projects. Asphalt Batch Plants. Al-Shalawi owns four Asphalt plants which are located in various places in the Kingdom such as Kharsaniyah, Dammam 2nd. Industrial Zone, Al Kharj and the Fadhli Gas Plant

Aggregate Site Project Coordinator Walbec Group

Continuously maintain, assist, and develop layouts and plans of crushing and wash plants, detailing plant layouts, material flows, screen sizes, products and TPH for quarry sites and products. Analyze equipment usage and needs, research and makes recommendations on new equipment to be purchased. Work with asphalt plant manager to coordinate

(PDF) Production and Uses of Crushed Rock Aggregate from

2021年10月3日The rocks will then be transported to the rock crusher, which begins the process of crushing the larger . the smaller capacity mobile plant works best for asphalt-aggregate recycling. The

11.19.1 Sand And Gravel Processing US EPA

11.19.1.1 Process Description1-6 produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although three-stage crushing may also be performed. At some plants, after initial crushing and screening, a portion of the sand may be diverted to construction sand use.

What should I know about a crusher plant? linkedin

2023年3月2日Crusher plants are used in aggregate production, mining, recycling, and in many other industrial processes. They are used to process materials such as rocks, ores, and other aggregates for the

Asphalt Batch Mix Plant Operation and Components

2017年10月7日Asphalt plants. The main components and operation of asphalt batch mix plant. It is to produce HMA known as Asphalt Batching Plant and hot mix plant. It blends together aggregates and bitumen to

Life Cycle Assessment of Greenhouse Gas Emissions from Recycled Asphalt

With the growing impact of climate change, there is an increasing need and obligation to reduce the responsible greenhouse gases (GHG) in road construction as well. Using life cycle assessment (LCA) methods, several studies have already separately analysed individual parameters of the asphalt production process and illustrated potential

Norwegian start-up Carbon Crusher has a way to repair roads

2022年3月17日Carbon Crusher’s road repair process uses recycled asphalt combined with a plant-based adhesive that they say is faster, cheaper, and actually sequesters carbon. A typical road is filled with

Abdulraman S.O and Olaleye B IJSER

Key words: Cash flow, crushing plant, quarry products, vertical shaft impactor —————————— —————————— 1.0 INTRODUCTION 1.1 Aggregate Quarrying Process and Quarry Products Granite aggregate quarrying is a multistage process by which granite rock deposit is extracted from the ground and crushed to

Turning the water off on aggregate washing with RCAS Quarry

2023年3月9日This principle is embedded in Kayasand’s flagship V7 crushing and screening plant. It is designed to produce accurately graded concrete sand from any type of aggregate material. “We [at Kayasand] see a future where quarries can turn off the water on their aggregate washing process and replace it with dry systems that transform waste

Al-Shalawi International Co. For TradingContracting

Aggregate Crusher plants. We apply stringent process control norms to ensure that quality products are delivered to customers and to our projects. Asphalt Batch Plants. Al-Shalawi owns four Asphalt plants which are located in various places in the Kingdom such as Kharsaniyah, Dammam 2nd. Industrial Zone, Al Kharj and the Fadhli Gas Plant

production process of aggregates MiningQuarry Plant

2013年3月7日NW Process Equipment specializes in production, automation, weighing and control equipment and systems for asphalt, aggregate and concrete plants. Karl Marx theory of the mode of Production as a cyclical

Machines Free Full-Text Developing and Testing of the Principle

In the current recycling process of reclaimed asphalt pavement (RAP), due to the serious damage of aggregate gradation and the large amount of aged asphalt still wrapped around the surface of the treated aggregate, the low recycling rate and poor performance of the recycled asphalt mixture are the major problems of RAP. In view of the shortcomings of

Aggregate Site Project Coordinator Walbec Group

Continuously maintain, assist, and develop layouts and plans of crushing and wash plants, detailing plant layouts, material flows, screen sizes, products and TPH for quarry sites and products. Analyze equipment usage and needs, research and makes recommendations on new equipment to be purchased. Work with asphalt plant manager to coordinate

The Complete Guide to Crushed Stone and Gravel gra-rock

2019年11月11日Unlike crushed stone, gravel is usually sold and used in its natural state. If it is crushed, gravel loses its unique smooth rounded texture and becomes crushed stone. It is important to note that some contractors refer to any stone in certain size ranges as “gravel,” even if it is crushed stone.

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.