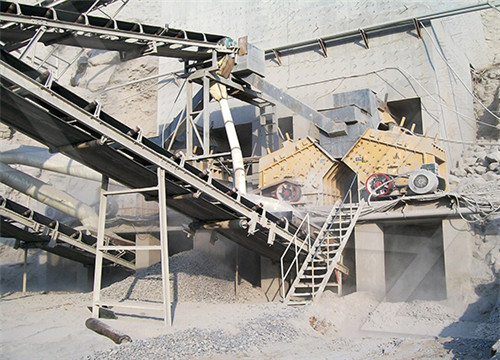

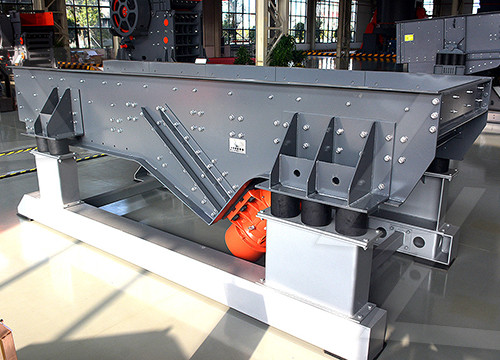

Nitriding For Roll Plates Of Stone Mining Mill

The Benefits of Nitriding and Nitrocarburizing Machine

2018年6月2日Nitriding is typically carried out at 450 to 520°C and nitrocarburizing at 540 to 580°C. These treatments are below the tempering or stress-relieving temperatures of steel, which are over 600°C.

Deep plasma nitriding and distortion control of large

2010年5月1日Article. Deep plasma nitriding and distortion control of large-sized mill slide plate. May 2010; Jinshu Rechuli/Heat Treatment of Metals 35(5):74-77

Nitriding Wikipedia

OverviewProcessesMaterials for nitridingHistorySee alsoFurther readingExternal links

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on low-alloy steels. They are also used on titanium, aluminium and molybdenum. Typical applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm comp

What is Nitriding? Benefits and Types of Nitriding Process

The main purposes of nitriding treatment are: To get high hardness on the surface. Hardness achieved in nitriding is usually higher than carburizing method. To increase

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日HPGR test results published by Grier (1992) on gold ores from the Mt. Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared

Rolling of Steel Plates in a Plate Rolling Mill IspatGuru

2021年2月8日For the rolling of the thin plate, the plate mill is required to be equipped with facilities for automatic shape control, flatness control, and gauge control. The mill

Steel Plate Rolling Services Heavy Plate Rolling

We are also capable of rolling light and heavy plate steel from 18” in diameter to 22’ in diameter. Some of the following characteristics make us stand out over the competition:

Mill liners Metso Outotec

Metso Outotec designs mill linings for optimal grinding performance. We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble

mill/sbm nitriding for jaw plates of stone crusher.md at

Contribute to crush2022/mill development by creating an account on GitHub.

Surface composition effect of nitriding Ni-free stainless steel as

2016年12月1日In order to increase the corrosion resistance of low cost Ni-free SUS445 stainless steel as the bipolar plate of a polymer electrolyte fuel cell, a nitriding surface treatment experiment was carried out in a nitrogen atmosphere under vacuum conditions, while an Ar atmosphere was used for comparison.

An Introduction to Nitriding ASM International

nitriding process as it is known today. Fry then investigated the effects of alloying elements on surface hard-ness. He discovered that the nitriding process produced a high surface hardness only on steels containing chromium, molybdenum, aluminum, 4/Practical Nitriding and Ferritic Nitrocarburizing Fig. 2 Schematic of a typical nitrided case

What is Nitriding? Benefits and Types of Nitriding Process

Nitriding is a thermochemical treatment process to enrich the surface with nitrogen for the purpose of increasing the surface’s hardness. The process is based on the low solubility of nitrogen in the ferritic crystal structure to promote the

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日By adding a Polycom high-pressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the power consumption by up to 20%. Large Polycom units provide a

12 Heat Treatment Processes: Annealing, Normalizing, Quenching

2023年1月31日The process of heating steel to a temperature that is 10-20 degrees higher than during quenching, after which quenching is performed, is referred to as quenching and tempering. After holding at high temperature, the steel is quenched, then tempered at a temperature range of 400-720 degrees.

Mill liners Metso Outotec

Metso Outotec designs mill linings for optimal grinding performance. We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills. Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, charge, expected service

Complete plate mill and meltshop for the new, 1.2 million

The plate/Steckel mill will consist of two stands: a roughing mill and a finishing/Steckel mill, also able to roll plates starting from 36” ingots. The complete design of the mill will allow the production of thermo-mechanical rolled plates and API grades, as well as high hardness wear-resistant plates up to a final plate width of 165.4

Construction Working and Maintenance of Practical Maintenance

Construction Working and Maintenance of Practical Maintenance

Products :: Cleveland-Cliffs Inc. (CLF)

Cleveland-Cliffs is the largest flat-rolled steel producer in North America and the largest supplier of automotive-grade steel in the U.S. We focus on high-quality, technologically advanced steel to meet exacting performance standards and customer requirements. We offer flat-rolled carbon steel, stainless, electrical, plate, tinplate, long

Milling ABC Hansen Africa provides, Maize Mills and Stone Mills.

The range of vertical and horizontal stone mills manufactured since 1925 in Denmark provides excellent milling quality. Diamond 300 and 500mm mills and Farmers Favorite 600 and 950mm stone mills are standard items. Stone mills are ideal for the milling of spices, because of the low milling temperature, thus preventing discoloration and loss of

Roller mill Wikipedia

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills.

1045 Steel Plate Kloeckner Metals Corporation

Advantages/Disadvantages. AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition. Because 1045’s chemical composition doesn’t include suitable alloying elements, it does not respond to nitriding.

(PDF) Hardening Roll Surface by Plasma Nitriding with

2017年5月4日Hardening Roll Surface by Plasma Nitriding with Subsequent Hardfacing View the table of contents for this issue, or go to the journal homepage for more 2017 J. Phys.: Conf. Ser. 830 012095

Surface composition effect of nitriding Ni-free stainless steel as

2016年12月1日In order to increase the corrosion resistance of low cost Ni-free SUS445 stainless steel as the bipolar plate of a polymer electrolyte fuel cell, a nitriding surface treatment experiment was carried out in a nitrogen atmosphere under vacuum conditions, while an Ar atmosphere was used for comparison.

An Introduction to Nitriding ASM International

nitriding process as it is known today. Fry then investigated the effects of alloying elements on surface hard-ness. He discovered that the nitriding process produced a high surface hardness only on steels containing chromium, molybdenum, aluminum, 4/Practical Nitriding and Ferritic Nitrocarburizing Fig. 2 Schematic of a typical nitrided case

What is Nitriding? Benefits and Types of Nitriding Process

Nitriding is a thermochemical treatment process to enrich the surface with nitrogen for the purpose of increasing the surface’s hardness. The process is based on the low solubility of nitrogen in the ferritic crystal structure to promote the

12 Heat Treatment Processes: Annealing, Normalizing, Quenching

2023年1月31日The process of heating steel to a temperature that is 10-20 degrees higher than during quenching, after which quenching is performed, is referred to as quenching and tempering. After holding at high temperature, the steel is quenched, then tempered at a temperature range of 400-720 degrees.

Complete plate mill and meltshop for the new, 1.2 million

The plate/Steckel mill will consist of two stands: a roughing mill and a finishing/Steckel mill, also able to roll plates starting from 36” ingots. The complete design of the mill will allow the production of thermo-mechanical rolled plates and API grades, as well as high hardness wear-resistant plates up to a final plate width of 165.4

Mill liners Metso Outotec

We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills. Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, charge, expected service life,

Products :: Cleveland-Cliffs Inc. (CLF)

Cleveland-Cliffs is the largest flat-rolled steel producer in North America and the largest supplier of automotive-grade steel in the U.S. We focus on high-quality, technologically advanced steel to meet exacting performance standards and customer requirements. We offer flat-rolled carbon steel, stainless, electrical, plate, tinplate, long

Our Dynamic HPGR Technology for Mineral Grinding Weir

Where HPGR technology has replaced traditional methods of crushing and grinding (e.g. SAG or ball mills), it has: Provided excellent throughput capacity and energy efficiency. Decreased energy consumption by up to 40%. Substantially reduced water consumption. Reduced recirculation and wear within crushing and grinding circuits.

Milling ABC Hansen Africa provides, Maize Mills and Stone Mills.

The range of vertical and horizontal stone mills manufactured since 1925 in Denmark provides excellent milling quality. Diamond 300 and 500mm mills and Farmers Favorite 600 and 950mm stone mills are standard items. Stone mills are ideal for the milling of spices, because of the low milling temperature, thus preventing discoloration and loss of

1045 Steel Plate Kloeckner Metals Corporation

Advantages/Disadvantages. AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition. Because 1045’s chemical composition doesn’t include suitable alloying elements, it does not respond to nitriding.