Gyratory Mining Mill Operation Costs

Equipment Cost Calculator Costmine

Current list prices to help you determine your capital budget for equipment. Hourly operating costs itemized for overhead, overhaul parts and labor,

AMIT 135: Lesson 5 Crushing Mining Mill Operator

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding

COST ESTIMATION FOR OPEN PIT MINES: TACKLING

2015年6月24日The results show that cost uncertainties likely have a critical impact on the profitability for when the mine operates the stable

Rock Crushing Rule of Thumb Mineral Processing

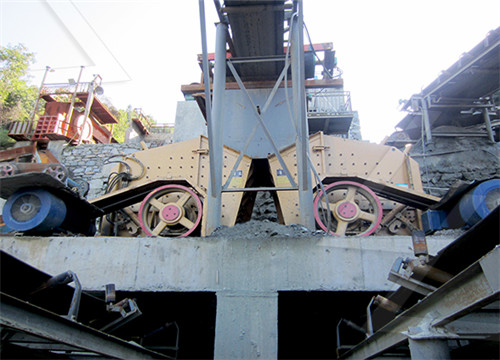

Crusher SelectionCrusher DesignCrusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application

The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreaker. For these reasons, most new installations are hydraulic, despite the higher capital c...For underground production rates less than 2,000 tpd, it may be economical to size theore underground with rockbreakers only, otherwise, an underground crusher is usually necessar The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreaker. For these reasons, most new installations are hydraulic, despite the higher capital c...For underground production rates less than 2,000 tpd, it may be economical to size theore underground with rockbreakers only, otherwise, an underground crusher is usually necessary when skip hoist...The operating cost for a stand-alone rockbreaker will be approximately 30% higher than it is for a crusher handling the same daily tonnage. Source: John GilbertThe capacity of one rock breaker on a grizzly with the standard opening (± 16 by 18 inches) is in the order of 1,500-2,000 tpd. Source: John Gilbert展开选择时,新内容将添加到焦点当区域上方在911metallurgist上查看更多信息

Operating Cost for Miners SRK Consulting

Mine cost estimation may be done at many levels. At first it may be a simple “back of the

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Better operation safety; Typical Cost of Grinding. The main costs for grinding are energy, liners and grinding media. They are different for different mill types. For tumbling mills: Diagram of cost breakdown by

Major MinesProjects Kevitsa Mine

Mining and mill throughput capaciites. Full profiles of select mines and projects. The

Agnico Eagle Mines Limited Operations Operations

Highlights of the report included planned annual production of 680,000 to 720,000 ounces

gyratory crusher operation costs conclusion about grinding

Contribute to lbsid/en development by creating an account on GitHub.

MineMill Equipment Cost Guide Costmine

The MineMill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with

Industrial Solutions Gyratory crushers ThyssenKrupp

designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-89 for iron ore.

Mineral Processing Plant Design University of Technology, Iraq

In mining operations, the layout of crushing plants and ancillary equipment and • Rising energy costs are causing owners to increase the integration of mine and mill design, so that they can identify ways of reducing overall electrical power The largest primary gyratory crushers cost US $2 million or more, while

Major MinesProjects Kevitsa Mine

Mining and mill throughput capaciites. Full profiles of select mines and projects. The Kevitsa Mine commenced mining operations in autumn 2011, Hartikainen was then contracted to mine waste from stage 1. Operating Costs: Units 2019 2018 2017; OP mining costs ($/t mined) EUR: 3.14: 2.98: 2.78: Processing costs ($/t milled)

Agnico Eagle Mines Limited Operations Operations Detour

Highlights of the report included planned annual production of 680,000 to 720,000 ounces of gold from 2021 to 2024, increasing to approximately 800,000 ounces in 2025, with anticipated all-in sustaining costs per ounce averaging $775 through 2025 and $821 over the 22-year production life.

Fuller®

With the acquisition of Traylor Engineering in 1959 came large-scale items such as kilns, mills, crushers, and other equipment suitable also for the mining industries. Fuller thereby achieved total plant capability, serving

What is the major step in the process of open-pit and underground mining?

2023年3月10日Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of access roads 4. Drilling and...

Which of the following mill used for fine grinding?

The roller mill minimizes such costs by precisely reducing feed materials with an average particle size up to 3⁄4 inch to a uniform average size typically between 100 and 2,000 microns. What is a mining mill? crushing, or cutting. Such comminution is an important unit operation in many processes. The grinding of solid materials occurs

How to start a gold ore mining business? linkedin

2023年3月6日To start a gold ore mining business, you need to understand the local laws and regulations related to gold mining, obtain the necessary licenses, develop a business plan to guide your operations

gyratory crusher operation costs conclusion about grinding

Contribute to lbsid/en development by creating an account on GitHub.

mill/sbm primary gyratory crushers in operation.md at master mill

mill. Watch 1 Star 0 Fork You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be mill /

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日The circuit has a single-line capacity of over 60,000 tpd. with the single HRC having 11.4 MW of installed power, and operating in conjunction with twin MP1250 cone crushers to feed twin 24 x 40-feet ball mills (26 MW for each of installed power).

Tips for Crusher Maintenance Thomasnet

2018年11月28日Check balance cylinder (s) every 30 days of operation. Keep oil and lubrication clean. Check daily, every 8 hours. Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis.

Gyratory Crusher Explained saVRee

Gyratory Crusher Operation Crushing action is produced by the oscillation or ‘ throw ’ (openingclosing) of the gap between the moving mantle liner, mounted on the central vertical shaft ( spindle ), and the fixed concave liners mounted on

MineMill Equipment Cost Guide Costmine

The MineMill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with

Industrial Solutions Gyratory crushers ThyssenKrupp

designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-89 for iron ore.

Mineral Processing Plant Design University of Technology, Iraq

In mining operations, the layout of crushing plants and ancillary equipment and • Rising energy costs are causing owners to increase the integration of mine and mill design, so that they can identify ways of reducing overall electrical power The largest primary gyratory crushers cost US $2 million or more, while

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日With a Gyratory primary crusher, these costs are kept at a minimum because the entire crushing circuit remains in balance. The concrete foundation may be modified for use as a surge bin. This storage

Major MinesProjects Kevitsa Mine

Mining and mill throughput capaciites. Full profiles of select mines and projects. The Kevitsa Mine commenced mining operations in autumn 2011, Hartikainen was then contracted to mine waste from stage 1. Operating Costs: Units 2019 2018 2017; OP mining costs ($/t mined) EUR: 3.14: 2.98: 2.78: Processing costs ($/t milled)

Fuller®

With the acquisition of Traylor Engineering in 1959 came large-scale items such as kilns, mills, crushers, and other equipment suitable also for the mining industries. Fuller thereby achieved total plant capability, serving

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

gyratory crusher operation costs conclusion about grinding

Contribute to lbsid/en development by creating an account on GitHub.

Which of the following mill used for fine grinding?

The roller mill minimizes such costs by precisely reducing feed materials with an average particle size up to 3⁄4 inch to a uniform average size typically between 100 and 2,000 microns. What is a mining mill? crushing, or cutting. Such comminution is an important unit operation in many processes. The grinding of solid materials occurs

How to start a gold ore mining business? linkedin

2023年3月6日To start a gold ore mining business, you need to understand the local laws and regulations related to gold mining, obtain the necessary licenses, develop a business plan to guide your operations

mill/sbm primary gyratory crushers in operation.md at master mill

mill. Watch 1 Star 0 Fork You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be mill /

Gyratory Crusher Wear Plates

OK™ Raw and Cement Mill; Mine shaft systems Mine shaft systems. Mine shaft equipment If more than one option is available, we offer cost-benefit options to make the decision-making process easier for you. Uptime is critical to the efficiency and success of your operation. The long wear life of our Gyratory Crusher Wear Plates keeps

HPGR High Pressure Grinding Rolls Mineral Processing

2016年7月13日The circuit has a single-line capacity of over 60,000 tpd. with the single HRC having 11.4 MW of installed power, and operating in conjunction with twin MP1250 cone crushers to feed twin 24 x 40-feet ball mills (26 MW for each of installed power).

Cone Crusher Explained saVRee

Introduction ‘Comminution’ is the term used to define the process that reduces materials (especially mined ore).It is the action of reducing a material to minute fragments or particles.The process is typically achieved in mining operations through stages of crushing and milling. In the past, mining activities were arduous and labour intensive.