Waste Stone Crushing And Lead-Zinc Conveyor Belt

11.19.2 Crushed Stone Processing and Pulverized

crusher product, normally 7.5 to 30 centimeters (3 to 12 inches) in diameter, and the grizzly throughs (undersize material) are discharged onto a belt conveyor and usually are

Conveyors Maximum Inclination vs. Product Engineering ToolBox

Maximum conveyor inclination slopes for typical products. Related Topics . Miscellaneous Engineering related topics like Beaufort Wind Scale, CE-marking, drawing standards and

进一步探索

Maximum Conveyor Angle of Inclination Mineral ProcessinConveyor Belt Inclination Conveyor Belt Maximum Slope 根据热度为您推荐•反馈

BELT CONVEYOR 911Metallurgist

2021年5月8日The belt conveyors used to transport the ore in the crushing plant commonly run at 100 to 200 ft. per min. and vary in width from 16 to 36 in. according to

11.19.1 Sand And Gravel Processing US EPA

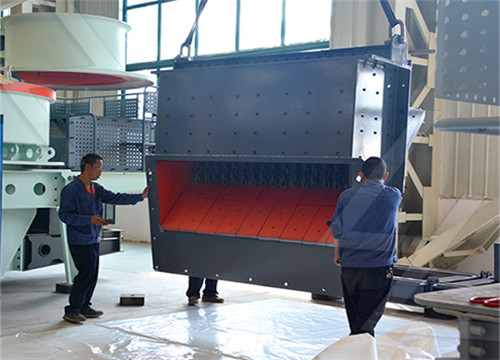

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone

Chat (mining) Wikipedia

Chat is fragments of siliceous rock, limestone, and dolomite waste rejected in the lead-zinc milling operations that accompanied lead-zinc mining in the first half of the 20th century. Historic lead and zinc mining in the Midwestern United States was centered in two major areas: the tri-state area covering more than 2,500 square miles (6,500 km ) in southwestern Missouri, southeastern Kansas, and

Comminution Multotec

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking,

sbm/sbm crushers for lead zinc orelead and zinc belt

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Environmental GUIDELINE ON STONE CRUSHING plant

The unloading area, crushers and conveyor belts to be enclosed and provided with dust suppression equipment. 2017 2017 ENVIRONMENTAL GUIDELINE ON STONE

What is a Crusher Conveyor Belt MIXING AND CRUSHING

2022年10月18日The belt conveyor is used for material conveying, using stainless steel mesh belt as the carrier, suitable for drying, dehumidification, freezing and heat

Lead-zinc ore crushing and grinding process mpl Ultrafine

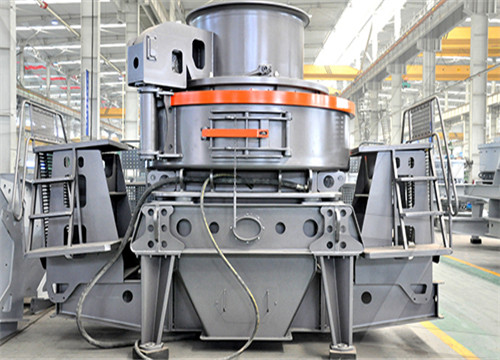

2022年6月10日The coarsely crushed lead-zinc ore is screened by a vibrating screen, and then sent to a single-cylinder hydraulic cone crusher (middle crushing) by a belt

Endless Conveyor Belts Smiley Monroe Conveyor belt

Conveyor belt experts. We are a leading global producer of endless conveyor belts and custom rubber parts for the materials processing equipment manufacturing sector. We serve 7 equipment segments: crushing, screening, recycling, washing, environmental, bulk material handling and road construction.

Aggregate Conveyor Systems Kemper Equipment

Overland Conveyors Overland conveyors can move material over sizeable distances and varying terrains while conveying as much as 6,000 TPH. Standard widths are 30 to 84 inches. These conveyors provide an economical alternative to trucking options through their reduced labor requirements.

Conveyors Maximum Inclination vs. Product Engineering ToolBox

Maximum conveyor inclination slopes for typical products. Related Topics . Miscellaneous Engineering related topics like Beaufort Wind Scale, CE-marking, drawing standards and more.; Related Documents . Angle of Repose Tipping or dumping angles for common materials like ashes, sand, earth, shingles and more.; Belt Transmissions Speed and

Smart Conveyor Control Using VFDs and Sensors Machine

2020年11月12日An AC induction motor that is being controlled by a VFD is running each conveyor A through E. In the non-digital age, all sensors were wired to a control contactor logic. Today’s digital VFDs

Rock Crusher MachinesPulverizers Williams Crusher

Then, gravity feeds the rock into the crusher where it is reduced. A belt feeder can also be used to constantly feed the rock into the crusher. Once in the crusher, rock is pressed into smaller pieces that fit through a hole. Once reduced, materials exit the crusher onto a conveyor belt, a bin, or a large pile. Different Types of Rock Crushers

Conveyor Bando USA

Pipe Conveyor Belts. Contact Daiki.Suehiro (at)bandogrp for conveyor belt information. Contact Us Today If you have questions, comments, need immediate assistance or more information, please don’t hesitate to call Bando USA at (630) 773-6600 or fill out our contact form by clicking the Contact Us Today button.

11.19.1 Sand And Gravel Processing US EPA

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone Processing." In the absence of other data, the emission factors presented in Section 11.19.2 can be used to estimate emissions from corresponding sand and gravel processing

Comminution Multotec

Crushing and grinding are common comminution processes, where the main aim is the liberation and reduction of the size of the ore. Crushing techniques make use of cone, jaw or gyroscopic crushers, yet grinding techniques are more often performed by milling, such as SAG or ball milling.

Repairing Rips and Tears in Your Conveyor Belt Flexco

2018年12月18日Here are a few best practices for rip repair in a variety of applications: For a small puncture, apply a standard bolt solid plate fastener crosswise on the belt over the damaged area. For a larger size hole, a patch of belting can be attached to the original belt using bolt solid plate fasteners. Remember to apply the corners first then the

Rock Crusher Eastman Rock Crusher

Granite is not easy to crush to sand, main equipment has PE-750×1060 jaw crusher (coarse crusher), HP300 cone crusher (fine crusher), bin, 490×110 vibrating feeder, B1000x22 conveyor belt, B1000x30m conveyor belt, B800x31 conveyor belt, 4YK2460 vibrating screen, etc. contact us!

HSE Quarries Safe operation and use of mobile jaw crushers

If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded. Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes

Chat (mining) Wikipedia

Mining and milling of ore produced more than 500 million tons of wastes in the tri-state area and about 250 million tons of wastes in the Old Lead Belt. More than 75 percent of this waste has been removed, with some portion of it used over the years. Today, approximately 100 million tons of chat remain in the tri-state area.

Home • Con Belt

About Con-Belt, Inc. Con-Belt, Inc. is a quality manufacturer of the most rugged and dependable standard conveyor belts, custom conveyor belting products, and replacement parts available. Our products are compatible and interchangeable with most major manufacturer’s conveyor equipment.

sbm/sbm crushers for lead zinc orelead and zinc belt conveyor

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Endless Conveyor Belts Smiley Monroe Conveyor belt

Conveyor belt experts. We are a leading global producer of endless conveyor belts and custom rubber parts for the materials processing equipment manufacturing sector. We serve 7 equipment segments: crushing, screening, recycling, washing, environmental, bulk material handling and road construction.

Aggregate Conveyor Systems Kemper Equipment

Our Expertise as Aggregate Conveyor Specialists. Kemper Equipment specializes in custom-designed, automated aggregate conveyor systems that bring numerous cost savings—and safety benefits—to aggregate mining operations. We've been helping quarries, mining operations, and asphalt companies improve efficiency, save money, and move

Conveyors Maximum Inclination vs. Product Engineering ToolBox

Maximum conveyor inclination slopes for typical products. Related Topics . Miscellaneous Engineering related topics like Beaufort Wind Scale, CE-marking, drawing standards and more.; Related Documents . Angle of Repose Tipping or dumping angles for common materials like ashes, sand, earth, shingles and more.; Belt Transmissions Speed and

Rock Crusher MachinesPulverizers Williams Crusher

Then, gravity feeds the rock into the crusher where it is reduced. A belt feeder can also be used to constantly feed the rock into the crusher. Once in the crusher, rock is pressed into smaller pieces that fit through a hole. Once reduced, materials exit the crusher onto a conveyor belt, a bin, or a large pile. Different Types of Rock Crushers

Smart Conveyor Control Using VFDs and Sensors Machine

2020年11月12日An AC induction motor that is being controlled by a VFD is running each conveyor A through E. In the non-digital age, all sensors were wired to a control contactor logic. Today’s digital VFDs

11.19.1 Sand And Gravel Processing US EPA

stockpiles by belt conveyors, bucket elevators, or screw conveyors. the impurities are floated in a froth and diverted to waste. The purified sand, which has a moisture screening, and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone Processing." In the absence of other data, the

Conveyor Bando USA

Pipe Conveyor Belts. Contact Daiki.Suehiro (at)bandogrp for conveyor belt information. Contact Us Today If you have questions, comments, need immediate assistance or more information, please don’t hesitate to call Bando USA at (630) 773-6600 or fill out our contact form by clicking the Contact Us Today button.

Repairing Rips and Tears in Your Conveyor Belt Flexco

2018年12月18日Here are a few best practices for rip repair in a variety of applications: For a small puncture, apply a standard bolt solid plate fastener crosswise on the belt over the damaged area. For a larger size hole, a patch of belting can be attached to the original belt using bolt solid plate fasteners. Remember to apply the corners first then the

Home • Con Belt

About Con-Belt, Inc. Con-Belt, Inc. is a quality manufacturer of the most rugged and dependable standard conveyor belts, custom conveyor belting products, and replacement parts available. Our products are compatible and interchangeable with most major manufacturer’s conveyor equipment.

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment. Stationary crushers include jaw crushers, impact

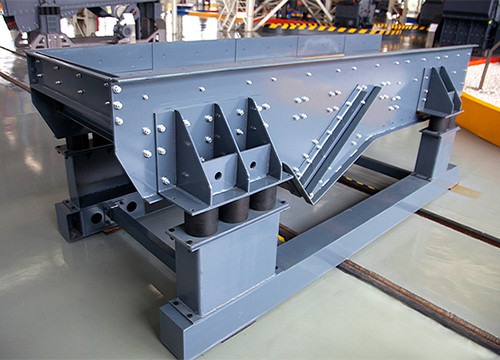

Belt Conveyor an overview ScienceDirect Topics

Recycling Technologies and Pollution Potential for Contaminated Construction and Demolition Waste in Recycling Processes. Zhao Youcai, Huang Sheng, in Pollution Control and Resource Recovery, 2017. 8.2.3.2 Belt Conveyor. Belt conveyor is necessary in the production line of gravel and construction waste, and is mainly used to connect the

Mining Tools in 2022—A Guide to Mining Equipment and

Drones. Underground mining drones, like Flyability's Elios 3, are used for visual inspections in stopes, ore passes, ventilation shafts, conveyor belts, and other areas of an underground mine.. Drone technology has allowed inspections to be conducted in areas that are unsafe for humans to enter, presenting an invaluable tool in such hazardous conditions.

What is a Crusher Conveyor Belt MIXING AND CRUSHING

2022年10月18日A crusher belt is a system that carries a belt conveyor, often referred to as a crusher belt. A crusher belt system consists of a number of belts. A crusher belt system consists of two or more pulleys with a closed loop of belts rotating around them. One or two pulley drives move the belt and material on it forward.

HSE Quarries Safe operation and use of mobile jaw crushers

If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded. Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes