Why Grind Size Is Important Copper Rock

Comminution an overview ScienceDirect Topics

3.2.2 Grinding3.2.2.1 Grind size and liberation of copper minerals. To isolate the copper-containing minerals into a concentrate, the ore should be finely enough ground to liberate the Cu mineral grains from the non-Cu mineral grains. The extent of grinding required to

进一步探索

COMMINUTION: Liberation, Crushing, GrindingComminution Mineral ProcessingMetallurgy(PDF) Comminution in mineral processing ResearchGateComminution WikipediaThe Importance of Comminution in Pharmaceutical Anal根据热度为您推荐•反馈

Metallographic grinding and polishing insight Struers

Grinding is the first step of mechanical material removal. Proper grinding removes damaged or deformed surface material, while limiting the amount of additional surface deformation. The goal is a plane surface with

Mineral processing metallurgy Britannica

根据热度为您推荐•反馈

Effect of P80 Grind Size on Flotation Collector

2017年10月2日The fine grind has 5.2% +210 microns while the coarse grind is 16.8% +210 microns. Six size intervals were tested: #1 being

Grain Size : What is Grain Size? How is Grain Size measured?

2020年8月21日The purpose of the analysis is to deduct the distribution of soil particle size. The analysis is carried out using two techniques. Sieve

Grinding and Polishing ASM International

face. An automatic grinding and polishing machine is shown in Fig. 4.1. Automatic grinding methodsteps are: 1. Symmetrically load three to six mounted specimens into the

Metallographic Polishing and Grinding Kemet

Abrasive belts or discs for wet grinding usually employ Silicon Carbide as the cutting media. Kemet Met Discs are plain backed and Bramet are Self Adhesive. Abrasive grit size is usually in the 120 320 range for rough

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日Evan Doran. Associate Editor. On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove

Why Is Grind Size Important? Mill City Roasters

2022年7月12日Our grind size plays a vital role in how we brew granite and significantly impacts the flavors we extract. Being able to adjust our grind size allows us to improve

Coffee Grind Size: Important Factors to Know and Why

2022年4月5日Grind size is how coarse or fine the granite beans are prepared. It is crucial because it affects the taste of your brew and how much flavor is extracted from the bean. Water is also key in the granite

Copper-processing technologies: Growing global copper supply

2023年2月17日Grind-circuit roughing, such as the CiDRA P29 system, 2 Can also be employed in a scavenger role at the end of the flotation circuit. addresses the challenge by recovering particles directly from the grind circuit. The system is based on the development of an innovative new material that acts as a so-called copper sponge, attracting and

Comminution an overview ScienceDirect Topics

Milling and grinding are the processes which serve the purpose of size reduction of solid particles of feedstock accomplished by ball mill, vibro, hammer, knife, two-roll, colloid, and propeller ( Zheng et al., 2014 ).

Metallographic grinding and polishing insight

Fine grinding produces a surface with little deformation that can easily be removed during polishing. Because of the drawbacks with grinding s, alternative fine grinding composite surfaces are available, in order to

Grain Size : What is Grain Size? How is Grain Size

2020年8月21日The purpose of the analysis is to deduct the distribution of soil particle size. The analysis is carried out using two techniques. Sieve Grain Size Analysis can measure the particle size ranging from 0.075

Grinding and Polishing ASM International

face. An automatic grinding and polishing machine is shown in Fig. 4.1. Automatic grinding methodsteps are: 1. Symmetrically load three to six mounted specimens into the specimen holder of an automatic grinding-polishing machine, with the flat sur-face of the ceramic section downward. Most manufacturers provide a

Metallographic Polishing and Grinding Kemet

Abrasive belts or discs for wet grinding usually employ Silicon Carbide as the cutting media. Kemet Met Discs are plain backed and Bramet are Self Adhesive. Abrasive grit size is usually in the 120 320 range for rough

Crushing in Mineral Processing

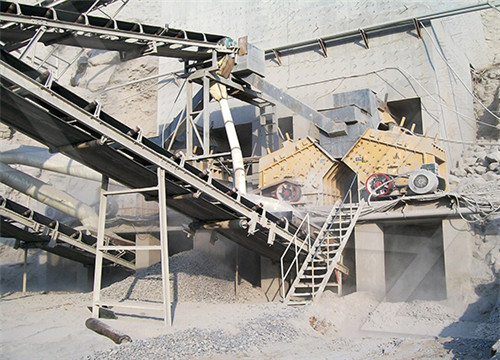

2015年12月26日In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Do's and Don'ts of Bench Grinding Wheels Norton

2013年3月1日Don’t adjust the work rest or tongue guard/spark arrestor while the grinding wheel is rotating. Don’t stand in front of or in line with a grinding wheel whenever a bench grinding machine is started. Don’t

Advantages and Disadvantages of Copper and Graphite

2002年1月1日"Particle size gives you strength, machinability and greatly influences the metal removal rate, wear and the surface finish. Graphite is made up of carbon particles that are put through a graphitizing process to produce graphite. The smaller the particle size is, the better the graphite.

Coffee Grind Size: Important Factors to Know and

2022年4月5日Grind size is how coarse or fine the granite beans are prepared. It is crucial because it affects the taste of your brew and how much flavor is extracted from the bean. Water is also key in the granite

Why Is Grind Size Important? Mill City Roasters

2022年7月12日The more open your filter is, the coarser your grind needs to be (the metal plunger on a French Press is a good example of a filter that requires a coarser grind size). Once you match your grind size to your filter, you can dial in the grind to taste. If your brew is tasting hollow, flat, or a little boring, try grinding a bit finer. If you

Metallographic Abrasive Grinding

It is an ideal abrasive for cutting and grinding because of its hardness and sharp edges. It is also somewhat brittle, and therefore it cleaves easily to produce sharp new edges (self sharpening). SiC is an excellent abrasive for maximizing cutting rates while minimizing surface and subsurface damage.

Introduction to Mineral Processing or Beneficiation Sepro Labs

2018年1月12日As the name implies, the grinding media in these mills are steel balls. The particles size of the feed usually does not exceed 2.5 cm. The grinding is carried out by balls being carried up the side of the mill such that they release and fall to the point where they impact the ore particles in trailing bottom region of the slurry.

Copper-processing technologies: Growing global copper supply

2023年2月17日Grind-circuit roughing, such as the CiDRA P29 system, 2 Can also be employed in a scavenger role at the end of the flotation circuit. addresses the challenge by recovering particles directly from the grind circuit. The system is based on the development of an innovative new material that acts as a so-called copper sponge, attracting and

Metallographic grinding and polishing insight

Fine grinding produces a surface with little deformation that can easily be removed during polishing. Because of the drawbacks with grinding s, alternative fine grinding composite surfaces are available, in order to

Grain Size : What is Grain Size? How is Grain Size

2020年8月21日The purpose of the analysis is to deduct the distribution of soil particle size. The analysis is carried out using two techniques. Sieve Grain Size Analysis can measure the particle size ranging from 0.075

SAG Mill Grinding Circuit Design Mineral

2016年6月6日Single stage AG/SAG milling. AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution. Inclusion of pebble-crushing circuits in the AG/SAG circuit. Circuits

Crushing in Mineral Processing

2015年12月26日In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Metallographic Abrasive Grinding

It is an ideal abrasive for cutting and grinding because of its hardness and sharp edges. It is also somewhat brittle, and therefore it cleaves easily to produce sharp new edges (self sharpening). SiC is an excellent abrasive

Metallographic Polishing and Grinding Kemet

Abrasive belts or discs for wet grinding usually employ Silicon Carbide as the cutting media. Kemet Met Discs are plain backed and Bramet are Self Adhesive. Abrasive grit size is usually in the 120 320 range for rough

Do's and Don'ts of Bench Grinding Wheels Norton

2013年3月1日Flange diameter must be equal to or greater than one-third the wheel’s diameter (e.g. 6 inch wheel, 2 inch flange). Do use flanges that are clean, flat, and smooth. Do make sure the bench grinder has the

Coffee Grind Size: Important Factors to Know and

2022年4月5日Grind size is how coarse or fine the granite beans are prepared. It is crucial because it affects the taste of your brew and how much flavor is extracted from the bean. Water is also key in the granite

How to Grind CoffeeDoes the Size Matter?

The grind size here wants to be somewhere between rock salt and normal salt, slightly rough to the touch and still visibly coarse. 4. Medium Coffee Grind Typically, this is the most common granite grind size you will find.

Why Is Grind Size Important? Mill City Roasters

2022年7月12日Our grind size plays a vital role in how we brew granite and significantly impacts the flavors we extract. Being able to adjust our grind size allows us to improve the quality of our cup, ensure that we can repeat the brew, experiment with extraction, create recipes, and more. Burr vs. Blade Grinders

sbm/sbm why grind size is important iron ore.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Introduction to Mineral Processing or Beneficiation Sepro Labs

2018年1月12日As the name implies, the grinding media in these mills are steel balls. The particles size of the feed usually does not exceed 2.5 cm. The grinding is carried out by balls being carried up the side of the mill such that they release and fall to the point where they impact the ore particles in trailing bottom region of the slurry.

Which Grinding Wheel Should I Choose? Norton

2018年11月21日When to select a coarse grit size: where the neatness of the surface finish is not essential to the project, a coarse grit can be used. Also, the coarser the grit, the more rapid the stock removal, which makes it more suitable for large areas of contact than fine gritted abrasives.