Ring Hammer Crusher With Greating Crushing Ratio

Hammer Crusher Eastman Rock Crusher

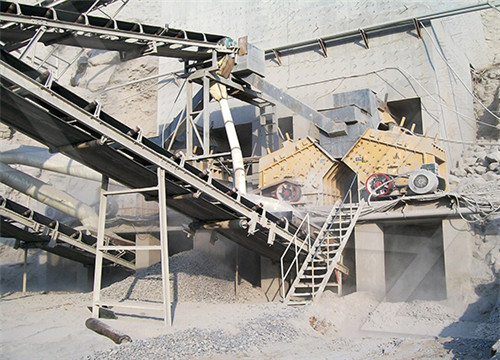

hammer Crusher Capacity 1-1120t/h Output size 10-350mm Hammer crusher is a kind of rock crusher equipment which can crush materials

Hammer Crusher Machine Big Crushing Ratio And High

Large crushing ratioand good grain shape of finished product. Because of our large hammer breaking ratio, more than 90% of the broken material is formed to less than

进一步探索

Technical Specification Of Hammer CrusherHammer Crusher Design PDF Crusher Mills, Cone Crushe根据热度为您推荐•反馈

RING HAMMER CRUSHER_ZK Ball Mill_Rotary

1. It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure, high weight and easy operation. 2. It can break material

PCH Ring Hammer Crusher Henan Turui Machinery

Get Main Advantages of PCH Series Ring Hammer Crusher 1. It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure,

What is the crushing ratio of the crusher? clirikchina

2021年8月13日2. Surface crushing ratio: the ratio of the width of the feed inlet of the crusher to the width of the outlet. Calculation formula: 1=0.85B/S (inlet width/discharge

Hammer Crusher For Sale Large Crushing Ratio, Good Crushing

What is hammer crushing machine? Hammer Crushers A variety of models are available Get the free price list! Feed particle size: ≤1200mm Capacity: 100-700T/H 【Applicable

Hammer Crusher afuruika

Hammer crusher is mainly used in medium crushing process, its structure is relatively simple, mainly composed of the engine body, head, the rotor with ring hammer, sieve,

Crusher Reduction Ratio Mineral Processing

2016年1月12日Generally, for such a case, the split would be about 3:1 to the standard machine, and 4:1 to the fine reduction crusher. Screening Crusher Feed High-Reduction-Ratio-Crusher Approximate Crusher

Crushing Ratio Competition of Different Crushers

The hammers are usually made of manganese. Uses impact and attrition to crush material. The crushing ratio is 20 to 1. These series products is character as high crushing

Hammer crusher PCH series Zhengzhou Dingsheng

Both dry crushing and wet crushing are available. The ring hammer crusher can also be applied for crushing fiber structure, scrap which has strong elasticity and toughness, waste , broken asbestos cement, etc. PCH Ring Hammer Crusher Features 1.The ring hammer crusher is designed with a simple structure, large crushing ratio and high

Hammer Crusher Henan Deya Machinery Co., Ltd.

2015年6月18日The hammer crusher is a machine that crushes materials in the form of impact and is divided into two forms: single rotor and double rotor. The single rotor is further divided into reversible and irreversible types. At present, single rotor hammer crushers and ring hammer crushers are widely used. Hammer crushers are mainly used for various

Hammer Crusher Machine Big Crushing Ratio And High

Large crushing ratioand good grain shape of finished product. Because of our large hammer breaking ratio, more than 90% of the broken material is formed to less than 50mm at one time. And the finished product has good grain shape, mostly polygons, less needles. Simple operation.

Ring Hammer Crusher|used for coal, stone crushing

Our Ring Hammer Crusher makes the crushing easy: 1) Compression Feeder helps constant feed and eliminates bulky item feed trouble. 2) Stable Horizontal Type Shedder (Heavy Duty Construction) 3) Ring-Type

Hammer Crusher ,hammer mill supplier, Walker Mining

Hammer crusher can directly crush materials with a particle size of 600-1800mm into a crusher with a size of 25 or less. The compressive strength of the crushed material shall not exceed 150 MPa. The hammer crusher can crush different sizes of raw materials into uniform particles, which is conducive to the next process.

Hammer Crusher DMW LOVOL Engineering

【 Hammer Crusher Features 】 1. High crushing ratio, the crushing ratio ranges from 10 to 25 or even higher to 50. 2. The output size can be adjustable by changing different mesh size screen, can be as fine as 1

Limestone crusher, crusging, comminution, jaw crusher, Hammer crusher

They are effective for hard and abrasive materials with low (<5%) moisture and give a reduction ratio of about 6:1. Hammer Crushers. Gyratory Crushers. operate by pressure between a gyrating cone and a stationary or spring-loaded crushing ring. Hard, abrasive materials like silcastone can be handled with reduction ratios of about 5:1.

Ring Granulator Type Coal Crusher Working

2016年11月13日Rotor assembly of crusher are statically/dynamically balanced to operate with minimum of vibration and noise. It consists of rotor shaft, end disc, arm, suspended bars, ring hammer and bearing sets.

Ring Hammer Coal Crusher China Ring Hammer Crusher and Impact Crusher

Ring Hammer Coal Crusher, Find Details and Price about Ring Hammer Crusher Impact Crusher from Ring Hammer Coal Crusher Harbin Hetai Electric Power Equipment Co., Ltd. CrushingCulling Machine. Ring Hammer Coal Crusher. FOB Price: US $ 10,000 / Piece: Min. Order: 1 Piece Min. Order FOB Price; 1 Piece: US $10,000/ Piece

Crushing Ratio Competition of Different Crushers

Uses impact to crush material. Crushing ratio is 20 to 1. The vertical shaft impact crusher is a crusher whose main mechanism rotates around a vertical axis. The rock is fed into the crusher and impacted or thrown by a table/ anvil configuration or anvil ring, and is crushed by impact either by manganese wear plates or rock-on-rock strikes.

HAMMER CRUSHER_ZK Ball Mill_Rotary Kiln_Grinding

It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure, high weight and easy operation. Hammer Crusher is a kind

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Hammer Crushers MEKA CrushingScreening

- Long lifetime Easy replacement of wear and spare parts through hydraulic opening device Broad range of applications High reduction ratio HAMMER CRUSHER TECHNICAL SPECIFICATION “Throughput capacity may vary depending on feed material size, grate opening, density, moisture content, friability and crushing application.

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日Cone crusher looks like gyratory crusher but without a steep crushing chamber. Just like jaw crusher, it is also a compression type crusher whose reduction ratio is 4:1 to 6:1. When cone crusher works, it uses the force between moveable mantle and stationary bowl liner to crush material.

Hammer crusher PCH series Zhengzhou Dingsheng

Both dry crushing and wet crushing are available. The ring hammer crusher can also be applied for crushing fiber structure, scrap which has strong elasticity and toughness, waste , broken asbestos cement, etc. PCH Ring Hammer Crusher Features 1.The ring hammer crusher is designed with a simple structure, large crushing ratio and high

Hammer Crusher Henan Deya Machinery Co., Ltd.

2015年6月18日The hammer crusher is a machine that crushes materials in the form of impact and is divided into two forms: single rotor and double rotor. The single rotor is further divided into reversible and irreversible types. At present, single rotor hammer crushers and ring hammer crushers are widely used.

PCH Ring Hammer Crusher Henan Turui Machinery

Get Main Advantages of PCH Series Ring Hammer Crusher. 1. It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure,

Ring hammer crusher > Grinding Equipment > Products > Mobile crusher

Ring hammer crusher machine can be used in both wet crushing process and dry crushing process. The suitable raw materials are coal, salt, plaster, brick and tile, limestone, etc. Ring hammer crusher not only can be used in the stone production line and sand production line, but also replace cone crusher in ore beneficiation process.

Ring Hammer Crusher|used for coal, stone crushing

Our Ring Hammer Crusher makes the crushing easy: 1) Compression Feeder helps constant feed and eliminates bulky item feed trouble. 2) Stable Horizontal Type Shedder (Heavy Duty Construction) 3) Ring-Type

Hammer Crusher For Sale Large Crushing Ratio, Good Crushing

The heavy hammer crusher has a large weight of individual hammerhead, reasonable rotor speed, and large rotational inertia of hammerhead, which can achieve the crushing effect of large feed size and small discharge size. The heavy hammer crusher for stone can be equipped with a low voltage motor, high voltage motor, and double motors.

Hammer Crusher DMW LOVOL Engineering

【 Hammer Crusher Features 】 1. High crushing ratio, the crushing ratio ranges from 10 to 25 or even higher to 50. 2. The output size can be adjustable by changing different mesh size screen, can be as fine as 1

Limestone crusher, crusging, comminution, jaw crusher, Hammer crusher

They are effective for hard and abrasive materials with low (<5%) moisture and give a reduction ratio of about 6:1. Hammer Crushers. In hammer crushers, hammers are mounted on discs strikes the stone fed into the crusher against breaking impact plates.

Ring Hammer Coal Crusher China Ring Hammer Crusher and Impact Crusher

Ring Hammer Coal Crusher, Find Details and Price about Ring Hammer Crusher Impact Crusher from Ring Hammer Coal Crusher Harbin Hetai Electric Power Equipment Co., Ltd. CrushingCulling Machine. Ring Hammer Coal Crusher. FOB Price: US $ 10,000 / Piece: Min. Order: 1 Piece Min. Order FOB Price; 1 Piece: US $10,000/ Piece

Crushing Ratio Competition of Different Crushers

Uses impact to crush material. Crushing ratio is 20 to 1. The vertical shaft impact crusher is a crusher whose main mechanism rotates around a vertical axis. The rock is fed into the crusher and impacted or thrown by a table/ anvil configuration or anvil ring, and is crushed by impact either by manganese wear plates or rock-on-rock strikes.

Demand for Coal Leads to the Development of Hammer Crusher

2013年3月21日The first step for coal production is crushing and the crushing ratio directly decides the quality and productivity of finished coal products. Therefore, choosing correct and suitable is the key point for high and stable productivity. As far as we know, ring hammer crusher is the most widely applied coal crusher and Daswell ring hammer

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Hammer Crushers MEKA CrushingScreening

Hammer Crushers. Hammer crushers of the type MHC are employed for the fine crushing of medium-hard to soft materials, like quicklime, dolomite, gypsum, limestone, diatomite, chalk. The material passes through the feed opening into the striking arc of the rotating hammers. The hammers throw the material against the breaker plates, from

Ring Hammer Crusher

1. It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure, high weight and easy operation. 2. It can break material with size of 600-1800mm directly into size of 25mm or below. Parameter Related Cases MORE >