Appilacations Of Jaw Crusher Uses Of Magnetic Powder In Coal Washery Process

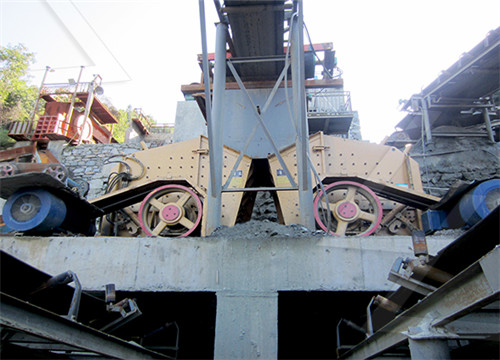

Application of 2PGL High-tenacity Double Roll Crusher in Xinghua

Apricot Xinghua Washery Preparation of the workshop process of transformation, with 2PGL-400 × 750 high-tenacity double roll crusher replacing two jaw crushers, resolved

Crushers an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator.

进一步探索

4 Types of Stone Crushers' Maintenance and Efficient ImprDifferent types of crushers for distinctive needs Metso Out根据热度为您推荐•反馈

ISO 8833:1989(en), Magnetite for use in coal preparation

In coal preparation, the mineral magnetite (FeO, Fe 2 O 3) has become the most commonly used material, not only because it fulfils all the above criteria, but also because of its

Magnetite recovery in coal washing by high gradient magnetic

Magnetite, slurried in water, is used to create an apparent heavy medium in which fine coal (0.1 to 2.4 mm) is cleaned of its mineral impurities. The magnetite is much finer in size (1

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日The gap between the two jaws narrows as the material moves through the crusher, further reducing the size. Jaw crushers are heavy duty machines and can be

applications of jaw crusher

2023年2月20日Here are some of the main applications of jaw crushers: Primary crushing: Jaw crushers are commonly used as primary crushers in mines and quarries

Jaw crusher types and applications News of Joyal Crusher

2021年6月24日Due to its simple structure, easy manufacturing, reliable work, and convenient maintenance, jaw crushers are widely used in metallurgy, mining, building

sbm/sbm use of magnetite iron ore in coal washery.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Coal crusher machine,coal grinding mill plant, mobile coal

Coal crushing plant acts as the key crushing plant in this process. Primary coal crusher works in the first stage of coal crushing process. Coal raw materials are firstly poured

Jaw Crusher an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日The gap between the two jaws narrows as the material moves through the crusher, further reducing the size. Jaw crushers are heavy duty machines and can be used in mining or quarry applications for very hard materials. Jaw crusher. Mineral sizers are one of the newer technologies to the crushing industry. They feature two rotors, each

University of Wollongong Research Online

The run-of-mine coal is reduced in size (to below ~30 mm ) by primary crushers, and after mixing with water is fed into a set of scalping screens (A in Figure 2). Large coal passes over these screens and is further processed in a dense medium cyclone plant (B), the overflow of which realises a fuel coal (26% ash) used for electricity generation.

Crushing Plant FlowsheetDesign-Layout Mineral Processing

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

applications of jaw crusher

2023年2月20日Here are some of the main applications of jaw crushers: Primary crushing: Jaw crushers are commonly used as primary crushers in mines and quarries to reduce the size of large rocks...

Need For Coal Beneficiation and Use of Washery Rejects

Workshop on Clean Coal Technology Power Plants are designed for a particular Coal Quality range and deviation in quality adversely affects the performance and efficiency of the Plant. The key area of concern are: Ash in coal As high as 45%. Inconsistency in Quality of Coal. Chemical Quality Physical Quality. These issues can by and large be addressed

Coal Washery Manufacturing Plant Detailed Project Report,

2016年5月17日In fact coal has been the world’s fastest energy source driven by Asian demand and regional abundance of fuel. Coal washery is an establishment where coal is alienated from slate and different impurities through various mechanical processes which utilize water and take gain of the difference in the specific gravity and its impurities of coal.

Coal Washery Waste Water Treatment using Natural

The process for having high quality coal requires wet cleaning process, the coal washery plants are used for washing the coals for improving its quality. In areas where there is demand for large volume of water for treating coal requires efficient recovery of water for the reuse and also for the area where is limited supply of water.

Jaw Crushers high quality and reliability from RETSCH

The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of application for a jaw crusher include building materials, mineralogy and metallurgy, ceramics and glass, materials science and environmental analysis.

Crusher an overview ScienceDirect Topics

This type of crusher is used in secondary or tertiary crushing applications. Advanced roll crushers are designed with one rotating cylinder that rotates toward a fix plate or rollers with differing diameters and speeds. It improves the liberation of minerals in the crushed product. Roll crushers are very often used in limestone, coal, phosphate

Size Reduction Equipment: Types, Applications, Construction, and

Jaw crushers vary in operating capacity and size, but as a rule, they lie somewhere in the mid of the full range of crusher size. In some instances, they may be made for portability, which is the case in most mining jaw crushers. Usually, their size is comparable to the size of a storage shed.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日The main equipment used are jaw crusher, ball mill, spiral classifier, magnetic separator, etc., and then properly configured with feeder, conveyor, etc., it can be equipped with a complete magnetic separation production line. The equipment used in this production line can be increased or decreased according to the actual situation.

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Jaw Crushers high quality and reliability from RETSCH

A jaw crusher is used for coarse and preliminary size reduction on a laboratory scale of medium-hard, hard, tough and brittle materials. This is often followed by further pulverization of the sample to analytical fineness in a laboratory mill. Typical materials include coal, ores, minerals, ceramics or building materials.

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日The gap between the two jaws narrows as the material moves through the crusher, further reducing the size. Jaw crushers are heavy duty machines and can be used in mining or quarry applications for very hard materials. Jaw crusher. Mineral sizers are one of the newer technologies to the crushing industry. They feature two rotors, each

University of Wollongong Research Online

The run-of-mine coal is reduced in size (to below ~30 mm ) by primary crushers, and after mixing with water is fed into a set of scalping screens (A in Figure 2). Large coal passes over these screens and is further processed in a dense medium cyclone plant (B), the overflow of which realises a fuel coal (26% ash) used for electricity generation.

Size Reduction Equipment: Types, Applications, Construction, and

Jaw crushers vary in operating capacity and size, but as a rule, they lie somewhere in the mid of the full range of crusher size. In some instances, they may be made for portability, which is the case in most mining jaw crushers. Usually, their size is comparable to the size of a storage shed.

Optimization of Coal Washery Tailings by Flotation Process

2019年10月17日The flotation performance was best when the amount of sodium hexametaphosphate (used as the depressant) was 4 kg/t; the recovery of clean coal was 71.88%, and the ash content was 10.64%. Flotation tailings are by-products of coal preparation plants, which do not only occupy cultivated land but also cause pollution.

Crushing Plant FlowsheetDesign-Layout Mineral Processing

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Crushers and Their Types IspatGuru

2015年4月3日Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two jaws of the crusher. Reduction ratio is usually 6:1. The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other than the bottom.

Process flow chart of Tasra coal washery ResearchGate

Raj S. Singh. Tasra coal washery has been planned in Tasra block which is located in Jharia coalfield of Jharkhand state in India. In order to predict air pollution impact because of the proposed

Coal Washery Manufacturing Plant Detailed Project Report,

2016年5月17日In fact coal has been the world’s fastest energy source driven by Asian demand and regional abundance of fuel. Coal washery is an establishment where coal is alienated from slate and different impurities through various mechanical processes which utilize water and take gain of the difference in the specific gravity and its impurities of coal.

Crusher an overview ScienceDirect Topics

When used underground, jaw crushers are commonly used in open circuit. This is followed by further size reduction in crushers located on the surface. When the run of mine product is conveyed directly from the mine to the crusher, the feed to the primary crusher passes under a magnet to remove tramp steel collected during the mining operation.

Jaw crusher parts Metso Outotec

Jaw design for your application. Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different one-piece jaws and two-piece jaws as well as cheek plates. Due to the wide range of applications and feed materials, our jaws are available in several different

How a Thickener Works Mineral ProcessingMetallurgy

2016年7月13日How a Thickener Works. Thickening or dewatering may be defined as the removal of a portion of the liquid from a pulp or slime made up of a mixture of finely divided solids and liquids. The early methods of thickening employed plain, flat-bottomed tanks into which the pulp was fed until the tank was full. The solids were then allowed to settle

Crushers an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is