Hammer Of Crusher Bearing Of Crusher

Determining the residual resource of the hammer

hammer crushers. Most of these crushers have a service life of 10 to 13 years and are objects with low reliability. Mostly emergency stops occur due to the destruction of the

Hammer Crusher Parts, What You Need to Know MIXING AND

2022年9月1日Hammer crusher is a common machine in the daily crushing industry. It is composed of different hammer crusher parts, each of which plays an important role.

9 Hammer Crusher Common Faults and Solutions Fote Machinery

High temperature of bearing. a. Lack of grease or too much grease; b. The bearings were

7 Hammer Crusher Common Problems And Solutions

The hammer crusher is widely used for fine crushing of medium hardness materials because of its high productivity and easy maintenance. The

What Are The Reasons for The Large Vibration Amplitude

2021年8月16日When reaching a certain speed, the vibration of the crusher will become more intense, and even may cause the hammer crusher to lose balance.The bearing

Hammer Crusher Parts EB Castworld % Hammer Crusher Parts

Hammer Crusher is a ring granulator type crusher consists of end disc, rotor shaft, rotor arm, suspended bar, spacer, bearing, linear, screen plate, etc.. Common alias: high

Hammer Crushers General PDF Bearing (Mechanical)

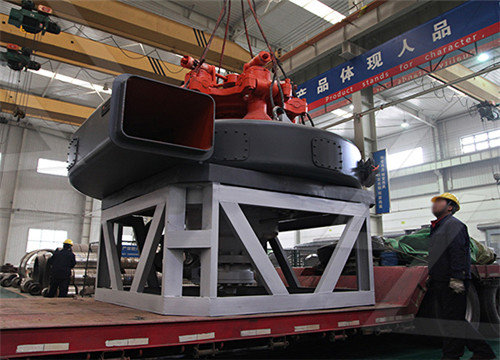

高达$3返现Hammer Crushers. The HDS rotor is a disc-type rotor, the rotor discs being removable attached to the. shaft and fixed in axial direction. The outer discs are pulled together by tension rods. Depending on the crusher

The Common Failures of Hammer Crushers JXSC Machine

2019年3月9日Design and machining defects, installation, debugging, maintenance process problems and man-made operation errors and structural wear and tear, deformation is the main source of hammer

Amazing Bearing Size of Jaw Stone Crusher Machine

2022年11月9日Amazing Bearing Size of Jaw Stone Crusher Machine || Hammer Boring Process in Local Workshop It’s cable reimagined No DVR space limits. No long-term

Knowing the Basics Leads to Better Care Timken Company

In hammer mills and horizontal crushers, spherical roller bearings in solid or split pillow block housings generally support the impactor shaft on both sides. Spherical roller bearings are a common choice because of their ability to handle the combination of radial loads and shaft misalignment that occurs during crushing.

Crushers an overview ScienceDirect Topics

Hammer crushers are used either as a one-step primary crusher or as a secondary crusher for products from a primary crusher. They are widely used for crushing hard metal scrap for different hard metal recycling processes. Pivoted hammers are pendulous, mounted on the horizontal axes symmetrically located along the perimeter of a rotor.

Hammer Crushers MEKA CrushingScreening

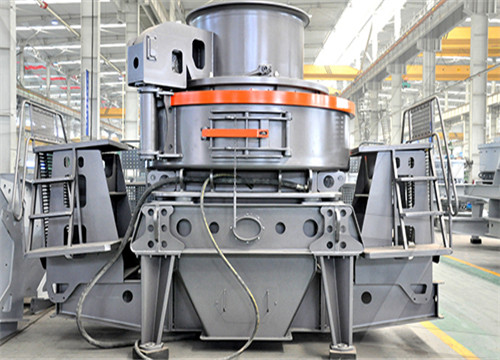

The rotors with shaft and bearings form the heart of a hammer crusher. As a disc rotor, it is equipped with freely-swinging hammers. MEKA Hammer Crushers have excellent accessibility to facilitate servicing and

Hammer crusher All industrial manufacturers

Find your hammer crusher easily amongst the 53 products from the leading brands (MEKA, Yuhang Heavy Industries, Dorr-Oliver Eimco,) on DirectIndustry, the industry specialist for your professional purchases.

Hammer Crusher Parts, What You Need to Know MIXING AND

2022年9月1日Hammer crusher is a common machine in the daily crushing industry. It is composed of different hammer crusher parts, each of which plays an important role. Last time we wrote about cone crusher parts and jaw crusher parts.

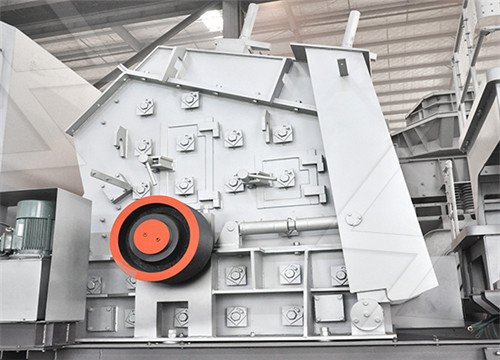

The difference between stone hammer crusher and impact crusher

2023年3月10日Hammer crushers use a single hammer to strike and break the material, while impact crushers use a combination of hammers and a crushing plate to strike and shatter the material.

Crushing Equipment PartsServices stedman-machine

For after-sales support, Stedman has a complete inventory of impact crusher wear parts and crusher spare parts including breaker bars, wear liners, bearings, electrical components, and shafts. Cage mill parts including sleeves, bands, and disks are stocked for quick cage assembly. Contact our experienced team to schedule your service.

Hammer Boring ProcessBearing Size of Jaw

2022年11月8日Hammer Boring ProcessBearing Size of Jaw Crusher Machine Fixing Up the Stone Crusher Machine.

Hammer Crushers General PDF Bearing

Hammer Crushers Method of Operation You can look inside jaw, cone and gyratory crusher while they are operating. The mechanical construction conforms to the method by which they work. These crushers operate by

Excavator accessories hydraulic crusher construction can accept

Excavator Accessories Hydraulic Crusher Construction Can Accept The Pile Breaker Provided With Bearing Q345b,Find Complete Details about Excavator Accessories Hydraulic Crusher Construction Can Accept The Pile Breaker Provided With Bearing Q345b,Skid Steer Breaker Attachment Mini Skid Steer Breaker Skid Loader Hydraulic

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by Using

2021年7月22日A coal crusher machine is used to crush the coal using hammers into the required size for better calorific value during combustion. This machine is at the heart of any thermal power plant or steel plant’s Coal Handling Unit. The pulverized coal is then fed into a furnace for combustion.

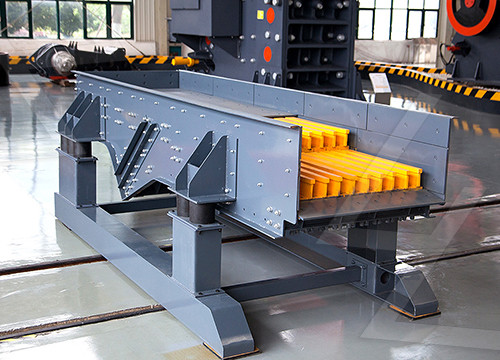

Ring Granulator Type Coal Crusher Working

2016年11月13日Rotor assembly of crusher are statically/dynamically balanced to operate with minimum of vibration and noise. It consists of rotor shaft, end disc, arm, suspended bars, ring hammer and bearing sets.

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日Impact Crushers: This division is a jaw, b cone, c mushroom, d hammer, e roller; 1 fixed cheek with the rotation axis; 2 a movable cheek; 3, 4 the eccentric shaft; 5 rod; 6 hinged rear bearing spacer cheeks; 7 spring; 8, 9 width adjustment mechanism of the discharge gap; 10 pull the lock

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

Knowing the Basics Leads to Better Care Timken Company

In hammer mills and horizontal crushers, spherical roller bearings in solid or split pillow block housings generally support the impactor shaft on both sides. Spherical roller bearings are a common choice because of their ability to handle the combination of radial loads and shaft misalignment that occurs during crushing.

Hammer Crushers MEKA CrushingScreening

The rotors with shaft and bearings form the heart of a hammer crusher. As a disc rotor, it is equipped with freely-swinging hammers. MEKA Hammer Crushers have excellent accessibility to facilitate servicing and

Hammer crusher All industrial manufacturers

HAMMER CRUSHER 750×260 is a hammer -rebound crushing machine. The fed material is crushed with repeated bumps of the hammer crusher MHC stationary abrasion wear plates. The rotors with shaft and

FT/FTE Flextooth Crushers J&B Industrial

the bearings. This ensures quick bearing removal without damaging the shaft. Hammer Design The unique crushing element (hammer) uses a cantilevered movement arm design with the movement controlled by a retainer pin. This hammer design permits the crusher to operate at relatively low speeds which minimizes fines,

Types of Crushers: What You Need to Know Machinery Partner

Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing. The hammers are attached to

Hammer Crusher Parts, What You Need to Know MIXING AND

2022年9月1日Hammer crusher is a common machine in the daily crushing industry. It is composed of different hammer crusher parts, each of which plays an important role. Last time we wrote about cone crusher parts and jaw crusher parts.

The difference between stone hammer crusher and impact crusher

2023年3月10日Hammer crushers use a single hammer to strike and break the material, while impact crushers use a combination of hammers and a crushing plate to strike and shatter the material.

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers:

Hammer Boring ProcessBearing Size of Jaw

2022年11月8日Hammer Boring ProcessBearing Size of Jaw Crusher Machine Fixing Up the Stone Crusher Machine.

Excavator accessories hydraulic crusher construction can accept

Excavator Accessories Hydraulic Crusher Construction Can Accept The Pile Breaker Provided With Bearing Q345b,Find Complete Details about Excavator Accessories Hydraulic Crusher Construction Can Accept The Pile Breaker Provided With Bearing Q345b,Skid Steer Breaker Attachment Mini Skid Steer Breaker Skid Loader Hydraulic

Crushing Equipment PartsServices stedman-machine

We have the crusher wear parts you need in stock to get you up and running fast 80% of parts orders ship same day! We electronically track your parts order from the moment it's placed, until the minute it's shipped Stedman specialists

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. When you need an Industrial Solution...

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

5 Glass Crushers to Accelerate Your Glass Recycling

2023年2月15日The glass hammer crusher is prone to blockage when processing sticky and wet glass materials, thus causing downtime (the moisture content of the materials should not exceed 10%). While crushing dry glass materials, it is easy to produce dust. Dust will enter the bearing and mix with the grease, resulting in poor lubrication and the