Outotec Ausiron? DXBlting Process

Ausmelt® TSL Process Metso Outotec

Operation Central to the Metso Outotec Ausmelt® TSL process is the use of a vertically suspended lance submerged in the slag layer of the molten bath. Injection of fuel and process gases (air and oxygen) result in

Energy Efficiency of the Outotec® Ausmelt Process for

2017年3月27日The Outotec® Ausmelt Top Submerged Lance Process is one such example, which has been widely adopted in the modernisation

Melting furnace AusIron Outotec pit / gas / for

Description Process iron ore fines efficiently with Outotec's flexible AusIron smelting reduction process for ironmaking, a unique solution developed from Outotec’s Ausmelt Top Submerged Lance (TSL)

(PDF) Outotec Ausmelt Top Submerged Lance (TSL) Lead

2014年5月15日• T echnical Director: Ausmelt, Australia (2006-2010 taken over by Outotec in 2010) • Leader furnace control group : Mintek,

(PDF) DECARBONISATION OF THE OUTOTEC ® AUSMELT

2019年8月18日The Outotec® Ausmelt Top Submerged Lance (TSL) Process has achieved widespread commercial acceptance over the past 40 years for the processing of copper, nickel, lead, tin, zinc and precious...

outotec ausiron 3 lting process cafebonbon85.fr

Minerals and Outotec have agreed to merge to create " Outotec" a company that will

outotec ausiron© smelting process garage-auto91.fr

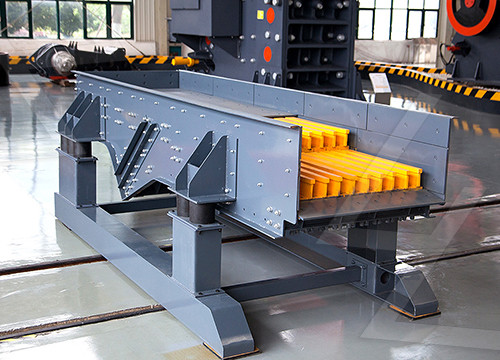

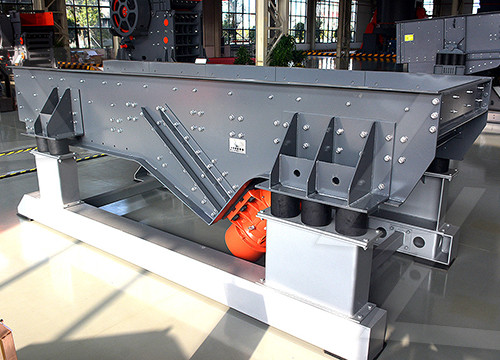

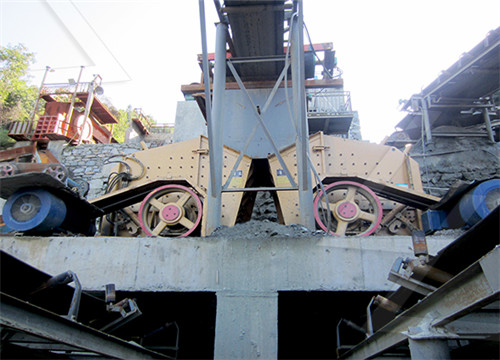

The Outotec AusIron process takes place in a purpose-built smelting reactor designed

en/outotec mining flow chart.md at main jidafang2022/en

Contribute to jidafang2022/en development by creating an account on GitHub.

Ausmelt® TSL Process Metso Outotec

Operation. Central to the Metso Outotec Ausmelt® TSL process is the use of a vertically suspended lance submerged in the slag layer of the molten bath. Injection of fuel and process gases (air and oxygen) result in

Melting furnace AusIron Outotec pit / gas / for

Description Process iron ore fines efficiently with Outotec's flexible AusIron smelting reduction process for ironmaking, a unique solution developed from Outotec’s Ausmelt Top Submerged Lance (TSL)

Sulfate Removal Process Metso Outotec

Our flexible sulfate removal process consists of a sulfate precipitation stage at pH 11–13 using lime milk and aluminum, followed by a final neutralization stage using carbon dioxide. Gypsum precipitation can be included before the sulfate removal stage when required. The process, built on easy-to-understand chemistry, can be applied to

Outotec® Pretium Calciner Optimizer Integrating Process

In this stone we present Outotec’s approach to combining process expert know-how, detailed simulation models, and operational experience with the goal of improving customer plant operation. Using our digitalization approach, the required know-how can be made available to ensure optimum plant operation 24/7. Recent success stories demonstrate

Outotec Circofer Coal-Based Reduction Plants Brochure

Based on over 60 years of experience in fluidized bed technology, Outotec has developed the Circofer coal-based process which produces pre-reduced feed material for smelting reduction reactors, such as AusIron, or electric smelting furnaces the final product being hot metal or pig iron. Contact supplier SEND

融解炉 AusIron Outotec ピット / ガス / 冶金

Outotec社の製品: 融解炉 AusIronに関するすべての情報をご覧ください。 効率的にプロセス鉄鋼の罰金Outotecのironmaking、OutotecのAusmeltの上によって水中に沈められる槍(TSL)の技術から開発される独特な解決のための適用範囲が広いAusIronの製錬の減少プ

outotec ausiron 3 lting process cafebonbon85.fr

Minerals and Outotec have agreed to merge to create " Outotec" a company that will deliver process technology and equipment to the minerals, metals and aggregates industries. The new combined company, which excludes Flow Control, has a combined sales total of €3.9 billion in 2018, or €4.2 billion including the recently

FUTURE DEVELOPMENT OPPORTUNITIES FOR THE

Process for copper matte converting at larger scale (1 t/h) was performed using a test plant at Olympic Dam that was operated in 1984 [4]. The first commercial scale application of

(PDF) DECARBONISATION OF THE OUTOTEC ®

2019年8月18日The Outotec® Ausmelt Top Submerged Lance (TSL) Process has achieved widespread commercial acceptance over the past 40 years for the processing of copper, nickel, lead, tin, zinc and precious...

outotec ausiron© smelting process garage-auto91.fr

The Outotec AusIron process takes place in a purpose-built smelting reactor designed to withstand high operating temperatures and turbulence through a combination of copper cooling elements at the bath level and boiler tubes membrane walls located at the upper part of the furnace...

en/outotec mining flow chart.md at main jidafang2022/en

Contribute to jidafang2022/en development by creating an account on GitHub.

Halmek Lithium chooses Metso Outotec's plant process

2021年6月30日Craig Guthrie. Halmek has ordered a Metso Outotec OKTOP Autoclave Plant, along with other engineering services and key equipment financial details were not disclosed. The plant is planned to have a capacity of 20,000 tons per year of lithium hydroxide monohydrate, when a first stage becomes operational in 2023, while a second

Used MiningProcessing Equipment Grinding Mills, CrushersProcess

2021年6月17日Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies. Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9

Metso Outotec to supply sustainable solvent extraction technology for

2021年12月17日By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5 degrees centigrade through climate targets certified by Science Based Targets.

Sulfate Removal Process Metso Outotec

Our flexible sulfate removal process consists of a sulfate precipitation stage at pH 11–13 using lime milk and aluminum, followed by a final neutralization stage using carbon dioxide. Gypsum precipitation can be included before the sulfate removal stage when required. The process, built on easy-to-understand chemistry, can be applied to

A New Era in Smelting Sustainability—Intensification of the Outotec

2020年1月1日The Outotec® Ausmelt Top Submerged Lance (TSL) Process has achieved widespread commercial acceptance over the past 40 years for the processing of copper, nickel, lead, tin, zinc and precious

FUTURE DEVELOPMENT OPPORTUNITIES FOR THE

Process for copper matte converting at larger scale (1 t/h) was performed using a test plant at Olympic Dam that was operated in 1984 [4]. The first commercial scale application of

Outotec® Pretium Calciner Optimizer Integrating Process

In this stone we present Outotec’s approach to combining process expert know-how, detailed simulation models, and operational experience with the goal of improving customer plant operation. Using our digitalization approach, the required know-how can be made available to ensure optimum plant operation 24/7. Recent success stories demonstrate

Thermal kiln Outotec rotary DirectIndustry

The SL/RN process was developed in the early 1960s by Outotec in collaboration with three US companies. The process principles are the basis for numerous rotary kiln plants and still represent the dominant

融解炉 AusIron Outotec ピット / ガス / 冶金

Outotec社の製品: 融解炉 AusIronに関するすべての情報をご覧ください。 効率的にプロセス鉄鋼の罰金Outotecのironmaking、OutotecのAusmeltの上によって水中に沈められる槍(TSL)の技術から開発される独特な解決のための適用範囲が広いAusIronの製錬の減少プ

utotec ausiron smelting process

The Outotec AusIron process takes place in a purpose built smelting reactor designed to withstand high operating temperatures and turbulence through a combination of copper cooling elements at the bath level and boiler tubes membrane walls located at .

outotec ausiron© smelting process garage-auto91.fr

The Outotec AusIron process takes place in a purpose-built smelting reactor designed to withstand high operating temperatures and turbulence through a combination of copper cooling elements at the bath level and boiler tubes membrane walls located at the upper part of the furnace...

outotec ausiron 3 lting process cafebonbon85.fr

Minerals and Outotec have agreed to merge to create " Outotec" a company that will deliver process technology and equipment to the minerals, metals and aggregates industries. The new combined company, which excludes Flow Control, has a combined sales total of €3.9 billion in 2018, or €4.2 billion including the recently

Decarbonizing steel production: Metso Outotec launches next generation

2021年12月7日Finding new solutions to decarbonize the steelmaking value chain is a must for the industry to become fossil-free and to help limit global warming to 1.5°C. To support the efforts, Metso Outotec is introducing the next generation of its Circored TM process for the direct reduction of iron ore fines. The game-changing process uses

Used MiningProcessing Equipment Grinding Mills, CrushersProcess

2021年6月17日Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies. Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion.

Halmek Lithium chooses Metso Outotec's plant process

2021年6月30日Instead of the more traditional sulfuric acid processing to produce lithium hydroxide, we decided to choose the Metso Outotec lithium hydroxide process as it is the most promising and environmentally sound process at the moment.

Decarbonizing steel production: Metso Outotec launches next

2021年12月7日The Circored TM process is based on the extensive fluidized bed knowledge and experience developed and applied by Metso Outotec over decades in hundreds of plants for different applications. The process applies a two-stage reactor configuration with a circulating fluidized bed (CFB) followed by a bubbling fluidized bed

otec ausiron smelting process

2022年5月24日The process, as shown in Fig. 8.11,is based on top submerged lance technology where coal, ferrous feed, flux and oxygen are injected directly into the smelter slag bath.The AusIron Process :: Total Materia Article,The AusIron process is a proprietary process developed primarily to tackle the task of directly smelting iron ore to